Construction method of tunnel steel arch feet-lock bolts

A technology of locking foot bolts and construction methods, which is applied to tunnels, tunnel linings, and installation of bolts, etc. It can solve problems such as delays in the construction period, exceeding the reserved value, and increased construction costs, so as to avoid random operation and accurate Simple positioning and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

[0018] Specific embodiments of the present invention are as follows:

[0019] a. After the excavation of the tunnel is completed, first spray concrete on the rock wall of the tunnel to seal the rock face, avoid long-term exposure of the rock face, and fill the uneven rock wall generated during excavation;

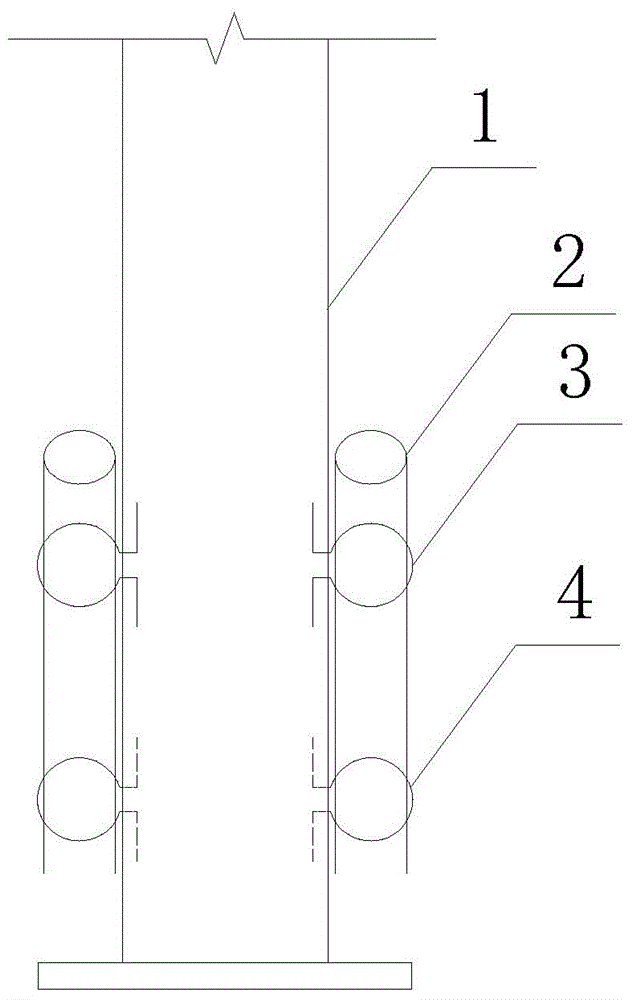

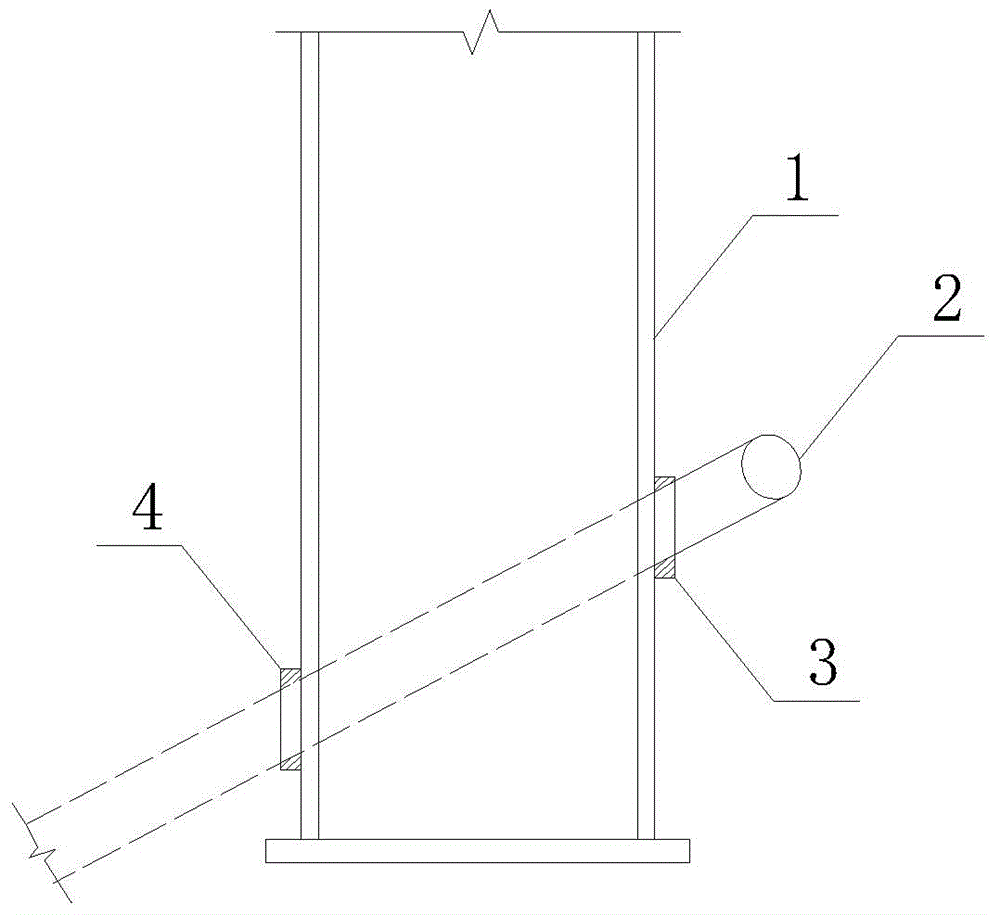

[0020] b. According to the determined angle of the anchor bolt (1) driven into the rock wall of the tunnel, two low-position positioning rings (3) are welded on one side of the steel arch (2), and two high-position positioning rings (3) are welded on the other side of the steel arch (2) 3), the positioning ring (3) is made of Φ22 steel bar and processed into an Ω shape; the distance between the high position positioning ring (3) and the connecting plate (4) is 30cm;

[0021] c. Install the steel arch (2) with the positioning ring (3) welded after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com