Leak detection system and method for air compressor

A leak detection and air compressor technology, which is applied in liquid tightness measurement using liquid/vacuum degree, pump test, mechanical equipment, etc. It can solve the problems of low manual detection efficiency, measurement of assembly process and parts quality, and missing detection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

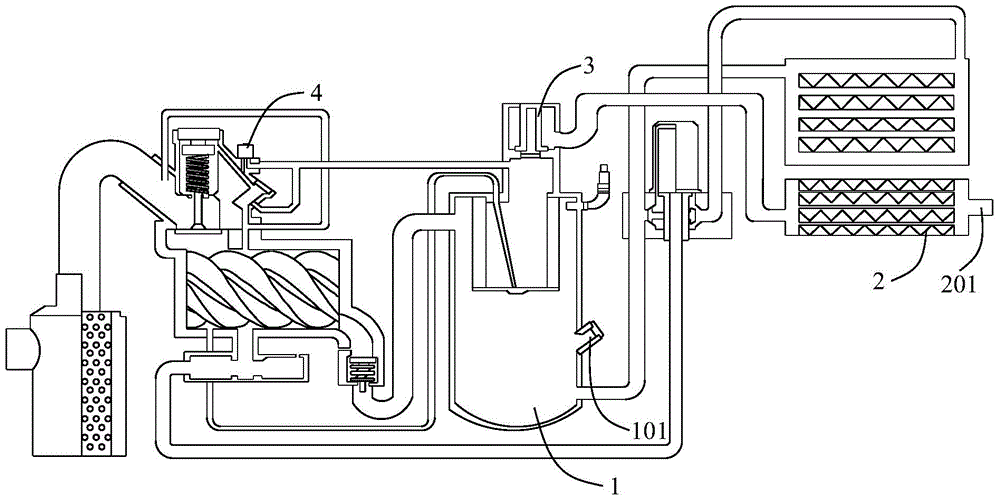

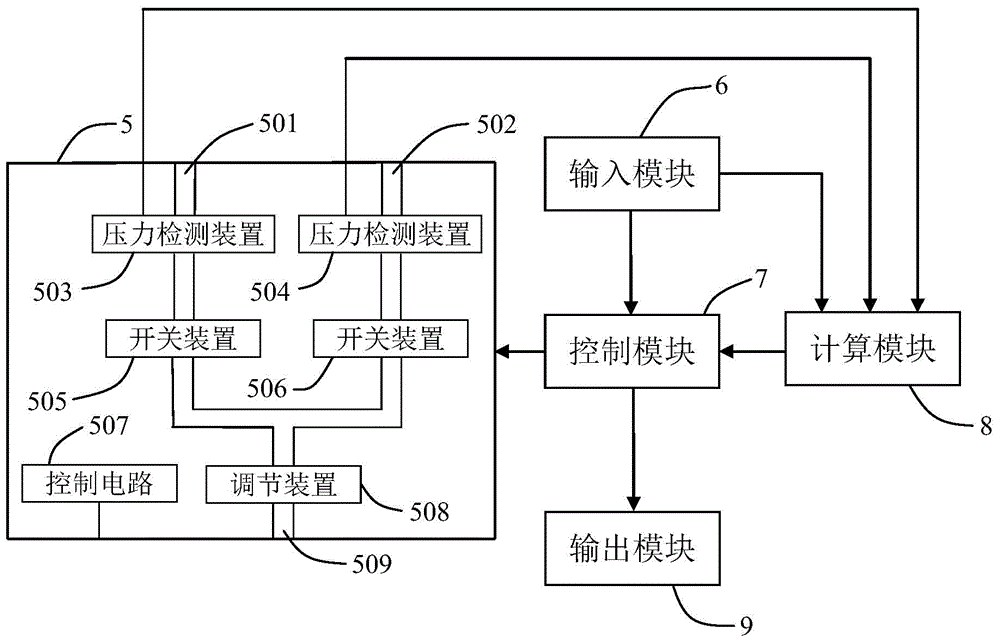

[0033] figure 1 It is a structural schematic diagram of a hollow air compressor in the prior art; figure 2 It is a structural block diagram of the leakage detection system of the air compressor of the present invention.

[0034] see figure 1 , the air compressor includes an oil-air separator 1 , an aftercooler 2 and a solenoid valve 4 for exhaust, the oil-air separator 1 has an oil inlet 101 , and the aftercooler 2 has an air outlet 201 . The leakage detection system of the air compressor of the present invention detects whether the leakage state of the air compressor is qualified. The so-called qualified leakage state means that the gas leakage of the air compressor is within the allowable range of leakage; the unqualified leakage state means that the gas leakage of the air compressor is not within the allowable range of lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com