Scroll refrigerating compressor with scroll plates adopting micro-groove end surface sealing structures

A refrigeration compressor and end face sealing technology, which is applied in the field of compressors, can solve the problems of accelerated scroll wear, reduced sealing performance, and large friction loss, and achieves high bearing capacity of the axial seal, reduced operating frictional moment, and zero The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

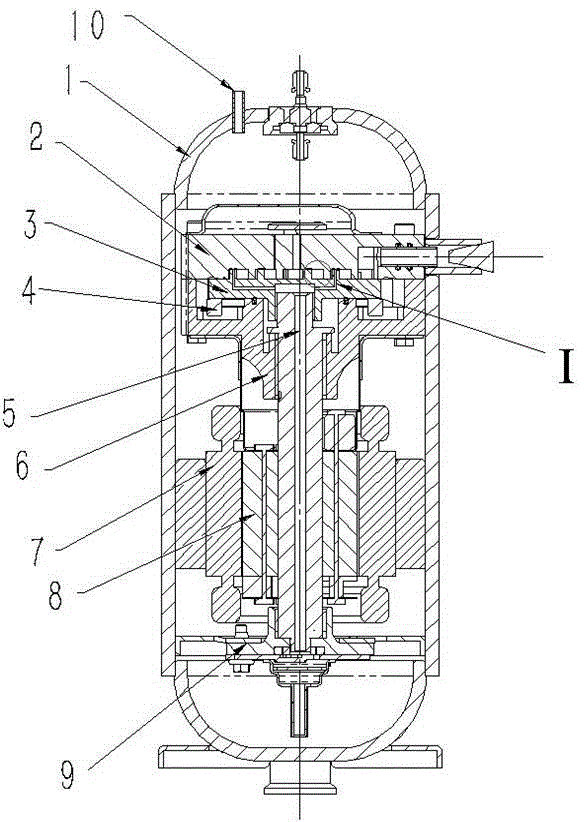

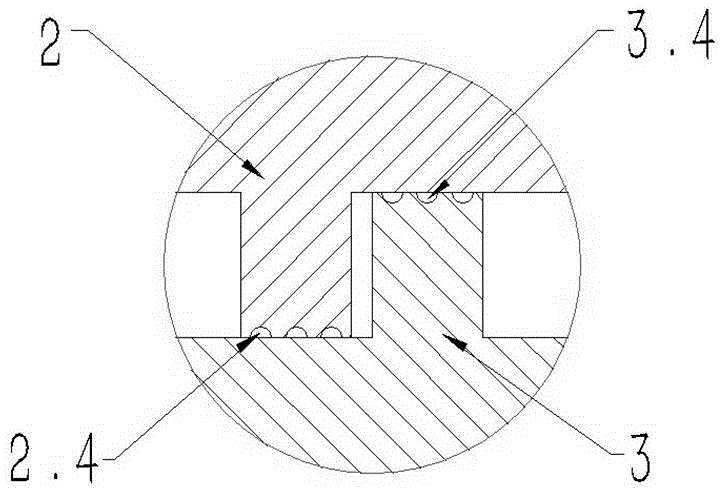

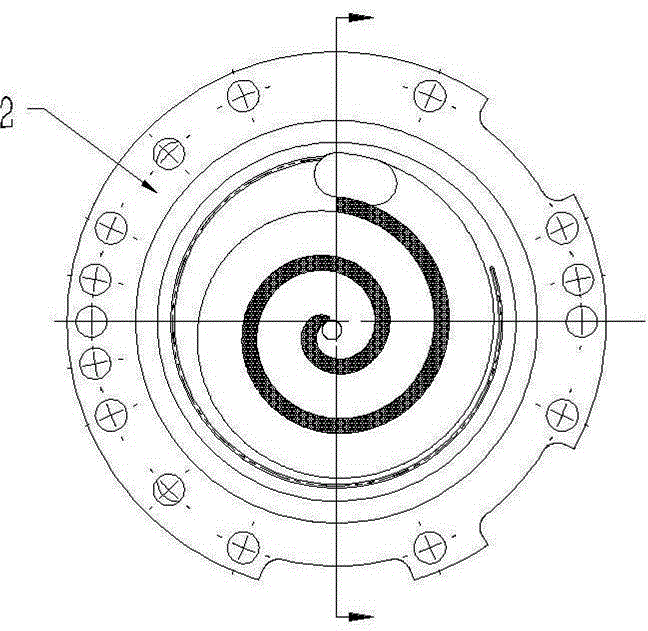

[0029] see figure 1 , the scroll refrigeration compressor with micro-groove end face seal structure scroll includes shell 1, fixed scroll 2, movable scroll 3, Oldham ring 4, crankshaft 5, upper support 6, motor, lower support 9 and exhaust pipe 10; The motor includes a motor stator 7 and a motor rotor 8. see image 3 and Figure 4 , the bottom surface of the fixed scroll 2 is provided with a fixed scroll 2.1, see Figure 6 and Figure 7 , The top surface of the movable scroll 3 is provided with a movable scroll 3.1, and the sealing is realized through the meshing of the fixed scroll 2.1 and the movable scroll 3.1. The improvements are:

[0030] see Figure 5 and Figure 8 , the tooth top surface 2.2 of the static disk scroll tooth 2.1 and the tooth top surface 3.2 of the movable disk scroll tooth 3.1 are respectively uniformly provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com