Novel multistage centrifugal pump

A centrifugal pump, a new type of technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of easy formation of air binding, poor sealing performance of multi-stage centrifugal pumps, low output efficiency, etc., to ensure the sealing performance , Reduce gas entry and liquid leakage, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

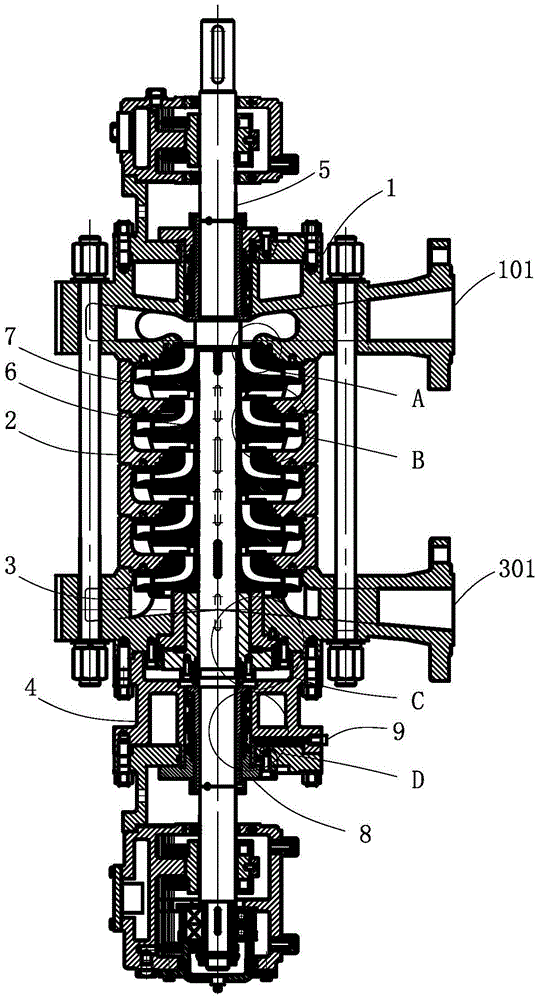

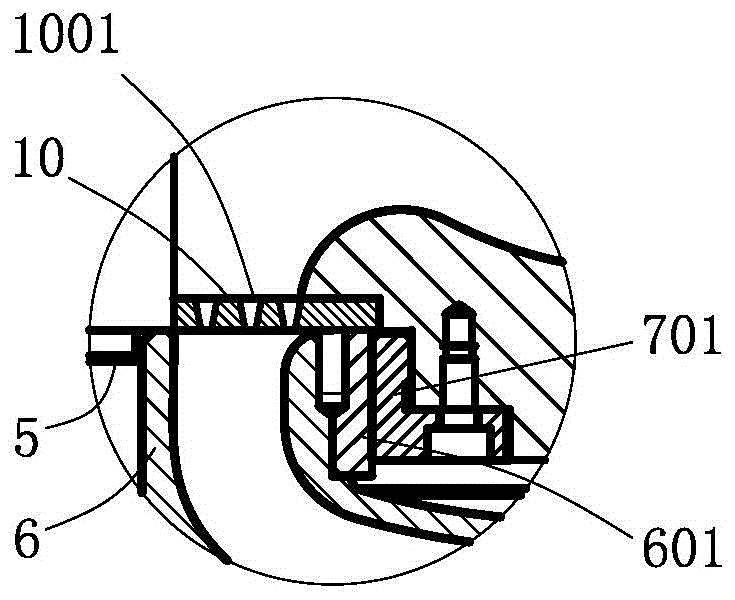

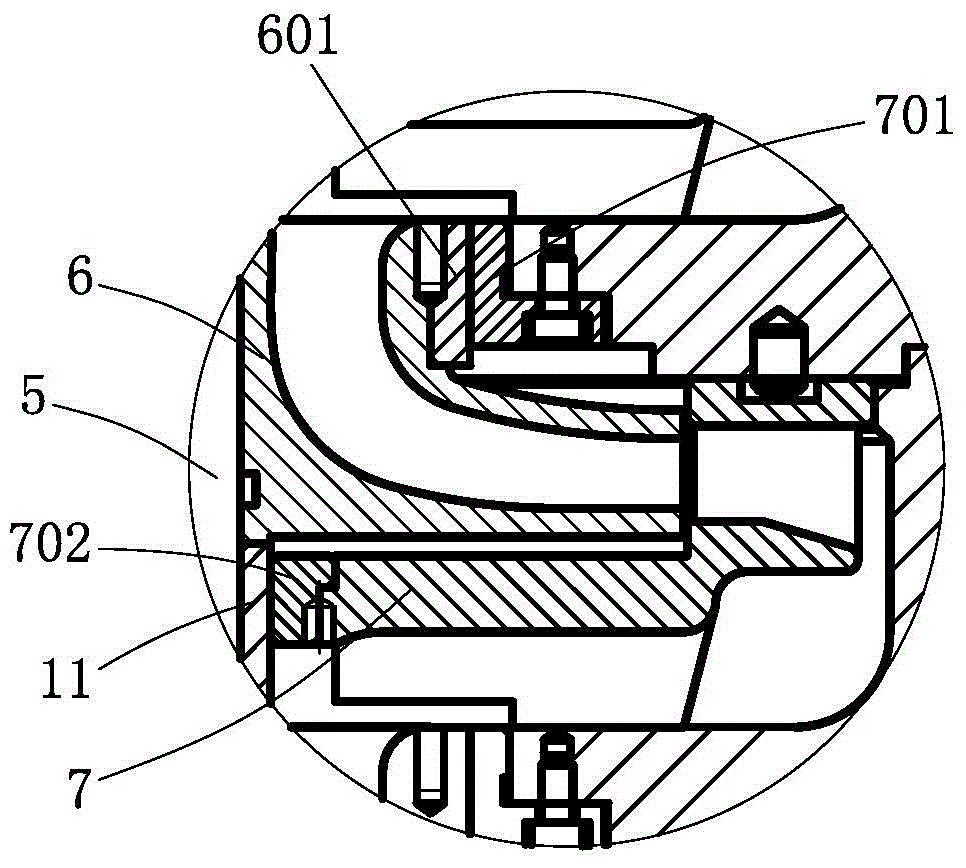

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Commonly shown, the present invention provides a multi-stage centrifugal pump, including a pump body, in which a drive shaft 5 is rotatably installed, and the pump body includes a suction section 1, a middle section 2 and a discharge section 3, and the middle section 2 is arranged on the suction section 1 Between the discharge section 3, the suction section 1 is provided with a suction port 101, and the discharge section 3 is provided with a discharge port 301. A number of impellers 6 are fixedly installed on the transmission shaft 5 located in the middle section 2, and the middle section 2 is provided with corresponding impellers 6. The guide vane 7 is provided with a suction sealing mechanism between the suction section 1 and the transmission shaft 5. Because it is negative pressure suction, the sealing mechanism of the suction section 1 can choose commonly used methods such as labyrinth seals and mec...

Embodiment 2

[0043] Such as Figure 6 shown, and refer to Figure 2 to Figure 5 , the present invention provides a multi-stage centrifugal pump, the structure of which is basically the same as that of Embodiment 1, the difference is that the pressure compensation channel 21 is not provided with a thrust rod 20, but the pressure compensation channel 21 is directly connected to the spout through a pipeline 28 The outlet 301 naturally balances the pressure on both sides of the sealing gasket 26 through the liquid pressure of the outlet 301, and automatically adjusts with the pressure change of the outlet 301, which is more convenient and accurate than using the thrust rod 20 to adjust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com