Condensate water air drying type top-mounted compression, condensation and evaporation integrated type refrigerator structure

A technology of condensing, evaporating and evaporating boxes, which is applied in the refrigeration industry, in the structural field of condensed water self-drying type upward compression condensing and evaporating integrated refrigerators, which can solve the problems of flowing, rusted equipment parts, complex structures, etc., and achieve the problem of dripping water, The effect of easy maintenance and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

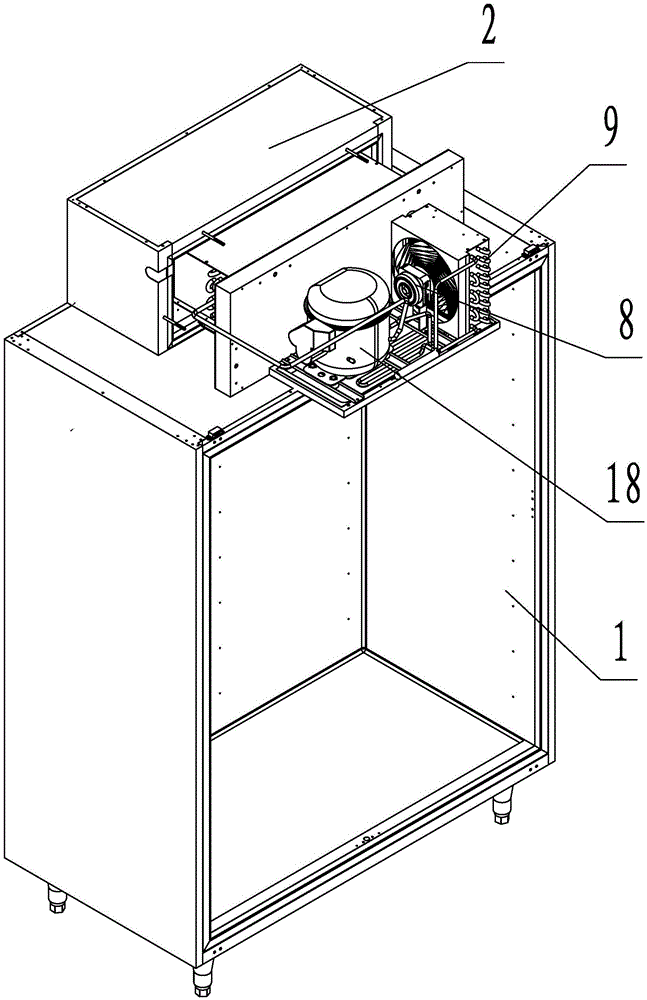

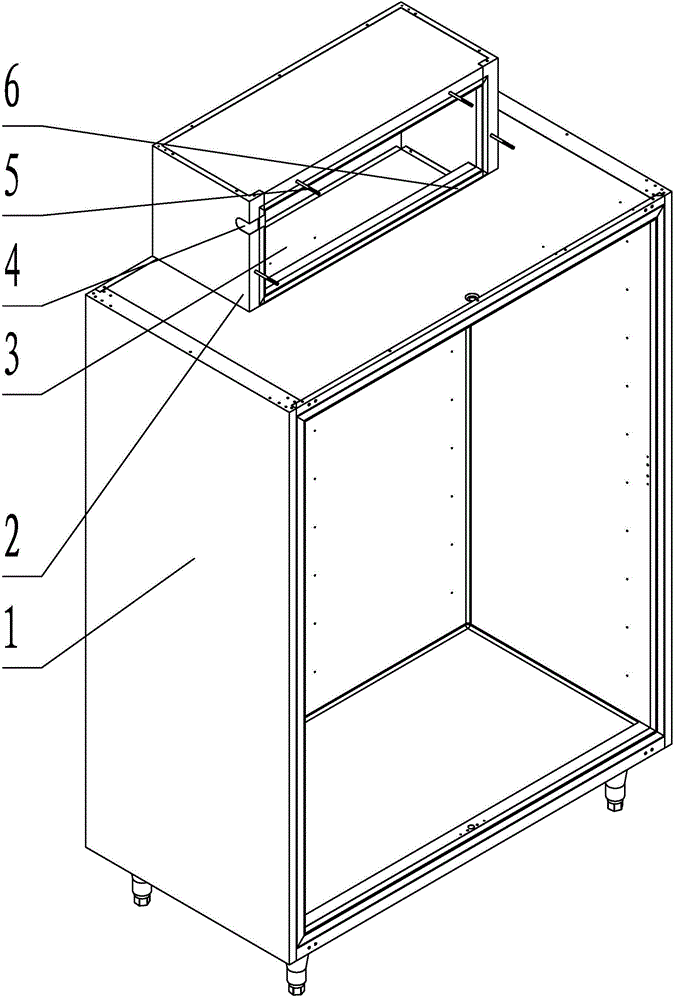

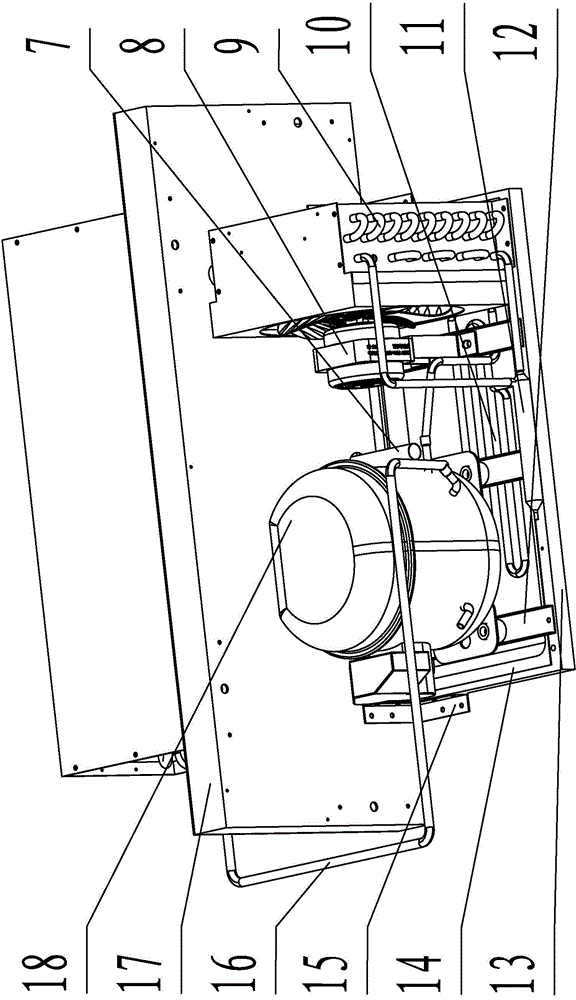

[0016] Such as figure 1 , figure 2 , Figure 5 As shown, the condensed water self-drying top-mounted compression condensation evaporation integral type refrigerator in this embodiment is composed of a cabinet and a refrigeration system. The cabinet is formed by integral foaming of the upper evaporation box 2 and the lower storage box 1. The evaporation box 2 and the storage box 1 have a through hole 3 for air circulation. The evaporating box 2 is equipped with an evaporating box cover 17, and the refrigeration system is respectively installed on the inner and outer sides of the evaporating box cover 17.

[0017] Such as image 3 As shown, the outside of the evaporator cover 17 is installed with a machine base plate 13 through a right-angled connecting bracket 15, and an evaporating pan 14 is installed on the machine base plate, and a shelf 12 is set on the evaporating pan. The heavier compressor 18, Condenser 9 and condensing fan 8 are all installed on the shelves. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com