Wireless detecting device for rotating speed and abrasion of hobbing cutter of shield machine

A technology of hob rotation speed and wireless detection, applied in measuring devices, instruments, etc., can solve the problems of inability to realize real-time monitoring of hob wear status, lack of universality, and large error rate, so as to reduce the risk of cutter head breakage, Flexible operation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following describes the present invention in detail in conjunction with the accompanying drawings and embodiments.

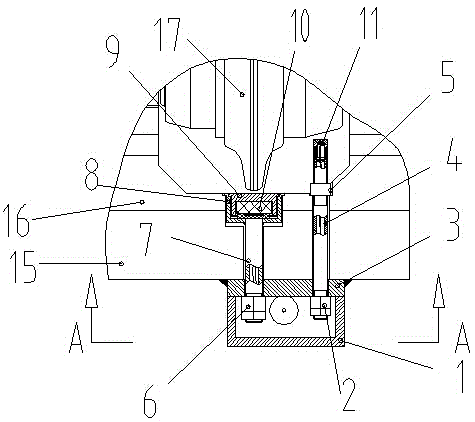

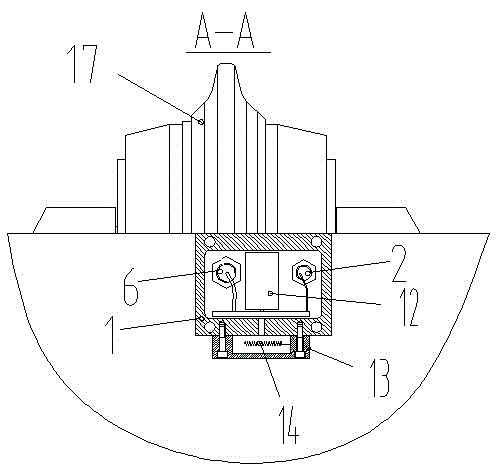

[0016] A wireless detection device for shield hob speed and wear, such as figure 1 and figure 2 As shown, it includes a protective cover 1 arranged at the lower end of the cutter head 15, and the protective cover 1 is detachable. A fixed flange 3 is provided between the cutter head 15 and the protective cover 1 , and the fixed flange 3 is welded to the cutter head 15 through accurate positioning. The protective cover 1 is fixed on the fixed flange 3 by four hexagon socket bolts around it. The size of the fixed flange 3 is 106×80×20mm.

[0017] The protective cover 1 is provided with a first nut 2 , a second nut 6 and a battery 12 . The first sleeve 4 is connected to the first nut 2 , and the first sleeve 4 passes through the third nut 5 fixed on the tool box 16 . The first sleeve 4 enters the knife box 16 after passing through the fixed flange 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com