Intelligent gear defect analysis method based on fractional wavelet transform and BP neutral network

A BP neural network and wavelet transform technology, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as the inability to characterize the local characteristics of the signal, and the inability to simultaneously achieve the resolution of the instant domain and the fractional domain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

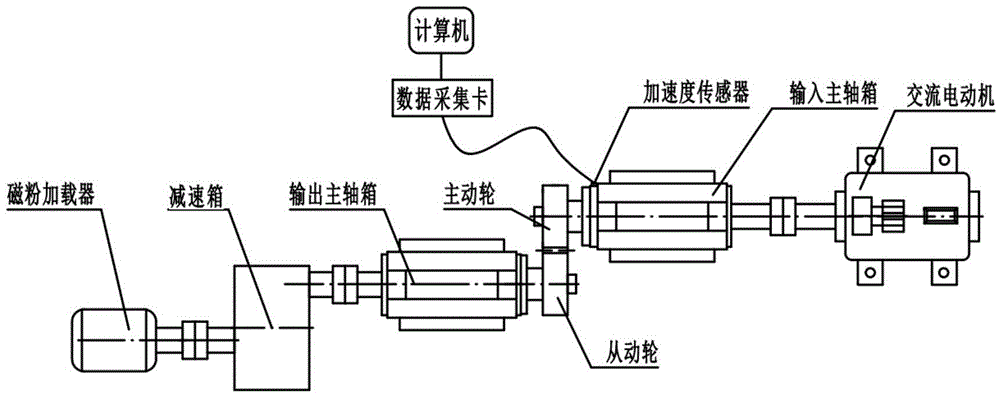

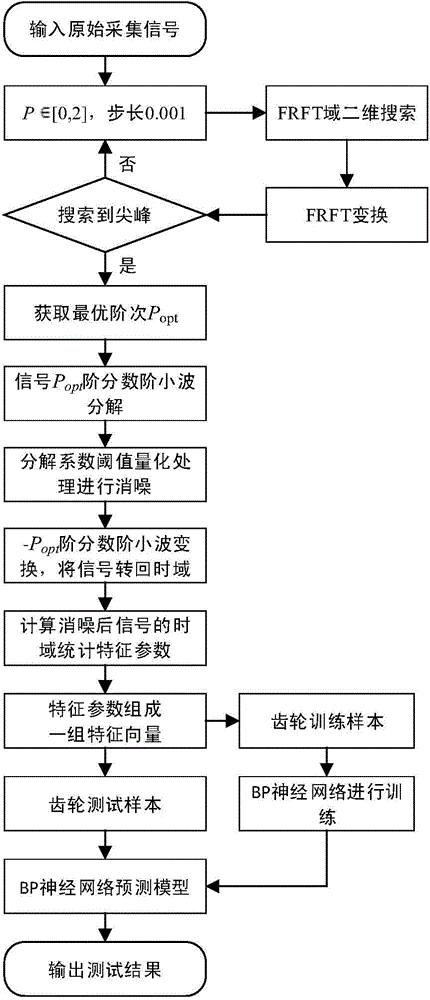

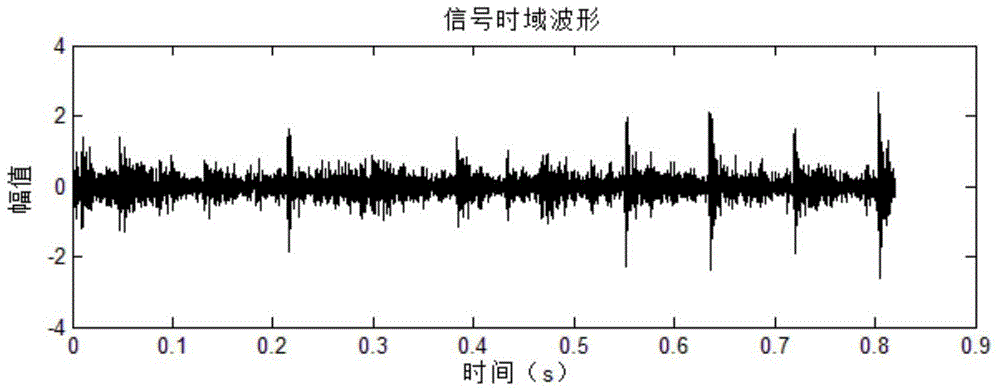

[0052] In the experiment, the attached figure 1 The experimental bench shown is used for gear vibration signal acquisition during the speed-up phase, because the gear vibration signal during the speed-up phase is similar to a chirp signal, which is conducive to fractional wavelet denoising, and the vibration signal is collected using an acceleration sensor. attached figure 2 It is the flowchart of intelligent analysis of gear defects. The time-domain and frequency-domain diagrams of normal meshing gears, gears with large meshing gaps and gears with small meshing gaps are shown in the attachment Figure 3a-3f As shown, the illustration shows that the three different modes of gears cannot be distinguished by observing the vibration signal waveform or spectral line, so the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com