A new method of manufacturing wire-wound inductors

A production method and technology of inductance, which is applied in the field of inductance, can solve the problems of power capacity and rated current that cannot meet the requirements of use, easy damage of winding and pin connections, poor performance indicators of color-coded inductance, etc., so as to facilitate installation into the circuit On the board, avoid winding displacement, the effect of large inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

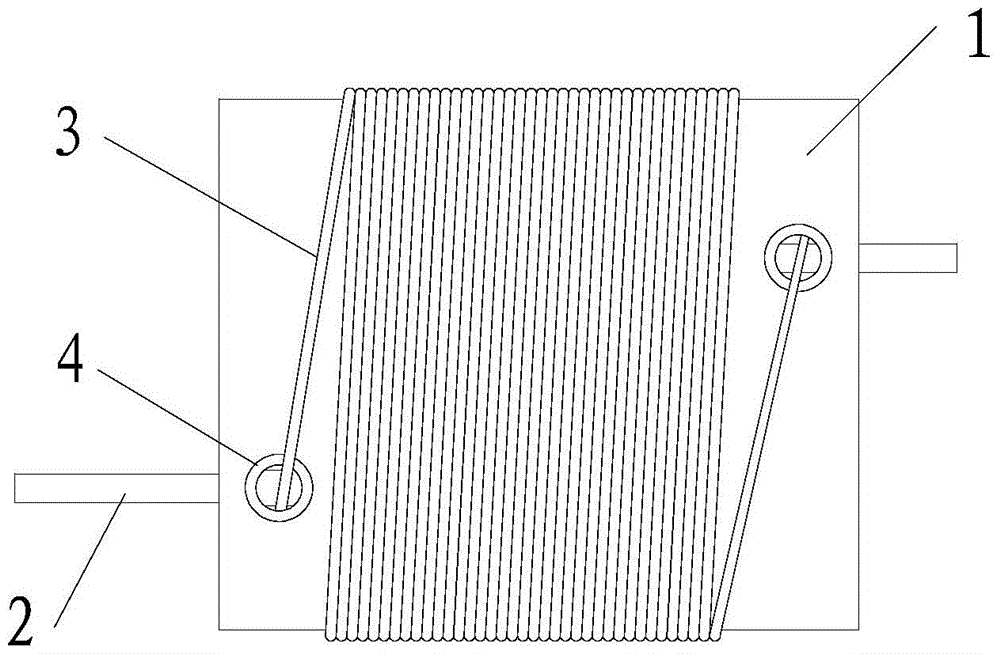

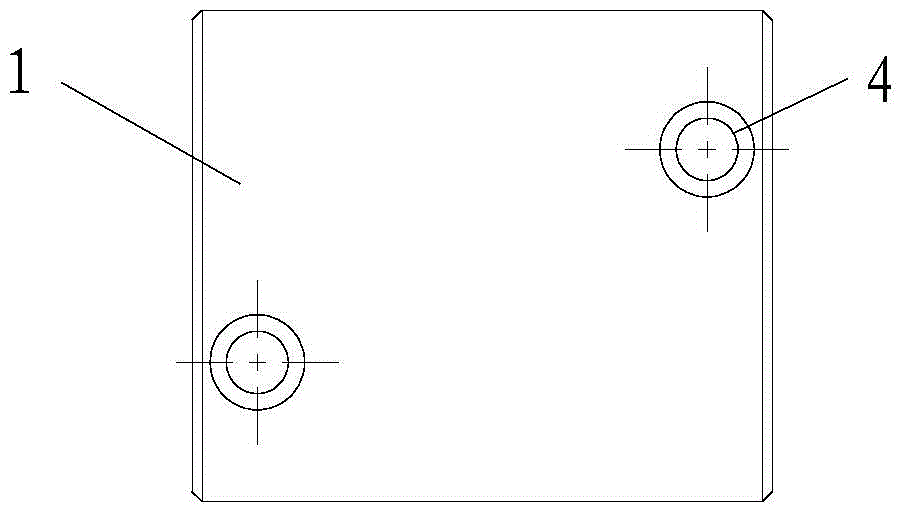

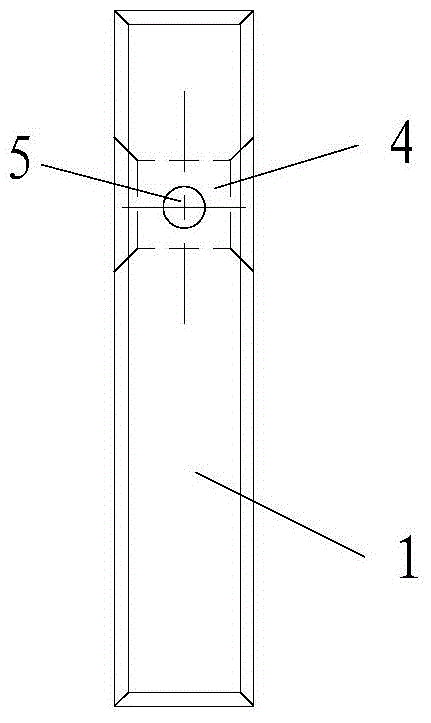

[0039] In this embodiment, the wire wound inductor has a structure such as figure 1 Shown; Inductor includes skeleton 1, winding 3 and two pins 2. Skeleton 1 is flat. figure 2 is a schematic diagram of the structure observed from the main view plane; image 3 It is a schematic diagram of the skeleton viewed from the right side. There are two wiring holes 4 on the front of the framework 1, and pin holes 5 are respectively opened on the two sides of the framework 1; each pin hole 5 communicates with the wiring hole 4 respectively; The connection between 5 and wiring hole 4 extends to the outside of frame 1 along pin hole 5 .

[0040] The winding 3 includes a main body and two positioning parts; the main body is wound on the skeleton 1; one end of the two positioning parts is respectively connected to the main body, and the other ends of the two positioning parts respectively extend into the wiring holes 4 to connect with the lead wires. The pins 2 are wound to form a conducti...

Embodiment 2

[0045] The wire-wound inductor in this embodiment includes a skeleton, a winding wire and two pins; the skeleton is flat; two wiring holes and two pin holes are provided on the skeleton; each pin hole is connected to the wiring hole; Each pin extends from the connection between the pin hole and the wiring hole to the outside of the skeleton along the pin hole; the winding is wound on the skeleton, and the two ends of the winding are respectively extended into the wiring hole to connect with the pins to form a conductive structure.

[0046] The frame of the inductor in this embodiment is flat, with less material and high mechanical strength, which can provide a larger winding space; compared with the traditional inductor, the inductor winding of this embodiment is wound along the flat frame, and the winding length Longer, it is beneficial to make an inductor with a large inductance; the skeleton is provided with wiring holes and pin holes for fixing the winding and pins, which ...

Embodiment 3

[0048] The structure of the inductor in this embodiment is as follows Figure 4 As shown, the difference from the first embodiment is that the frame 1 is provided with a positioning slot 1 6 and a positioning slot 2 7 communicating with the wiring hole 4 . The other ends of the two positioning parts of the winding wire 3 respectively extend into the wire routing hole 4 through the positioning groove one 6 to be wound with the pin 2 . The positioning groove 16 can effectively fix the position of the winding wire 3, so that the winding wire 3 is tightly wound, avoiding looseness, and improving the mechanical strength of the inductor; at the same time, it is convenient for processing.

[0049] The winding 3 also includes two reinforcing parts; one end of the two reinforcing parts is respectively connected to the other end of the two positioning parts, and the other ends of the two reinforcing parts extend to the outside of the skeleton 1 along the positioning groove 7 and are wou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com