Pneumatic tire

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, reinforcing layers of pneumatic tires, tire parts, etc., which can solve the problems of increased tire rolling resistance, decreased handling stability, and reduced carcass ply, so as to reduce rolling resistance , achieve light weight and improve the effect of delamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

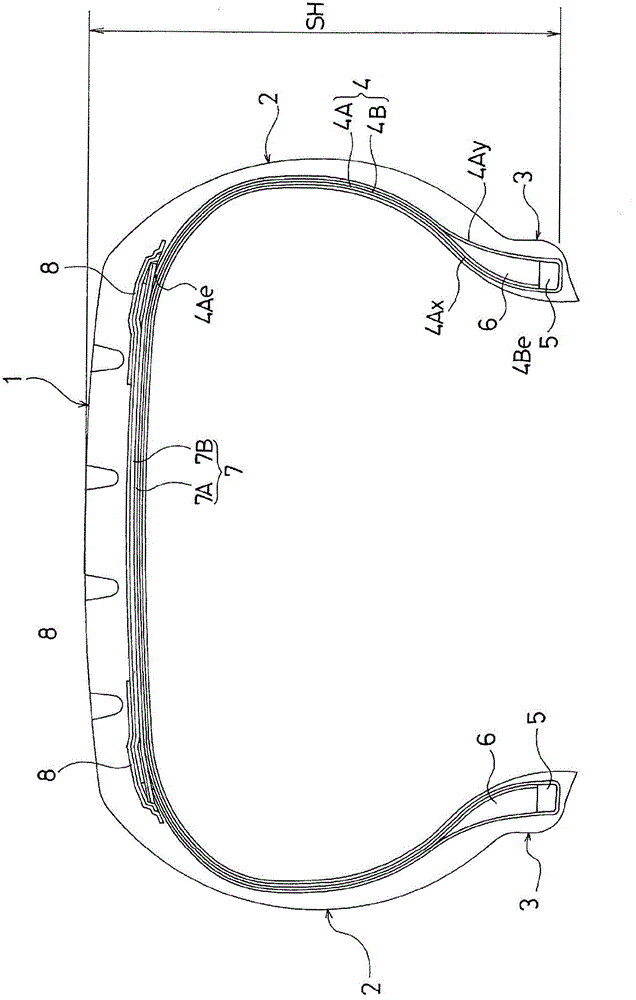

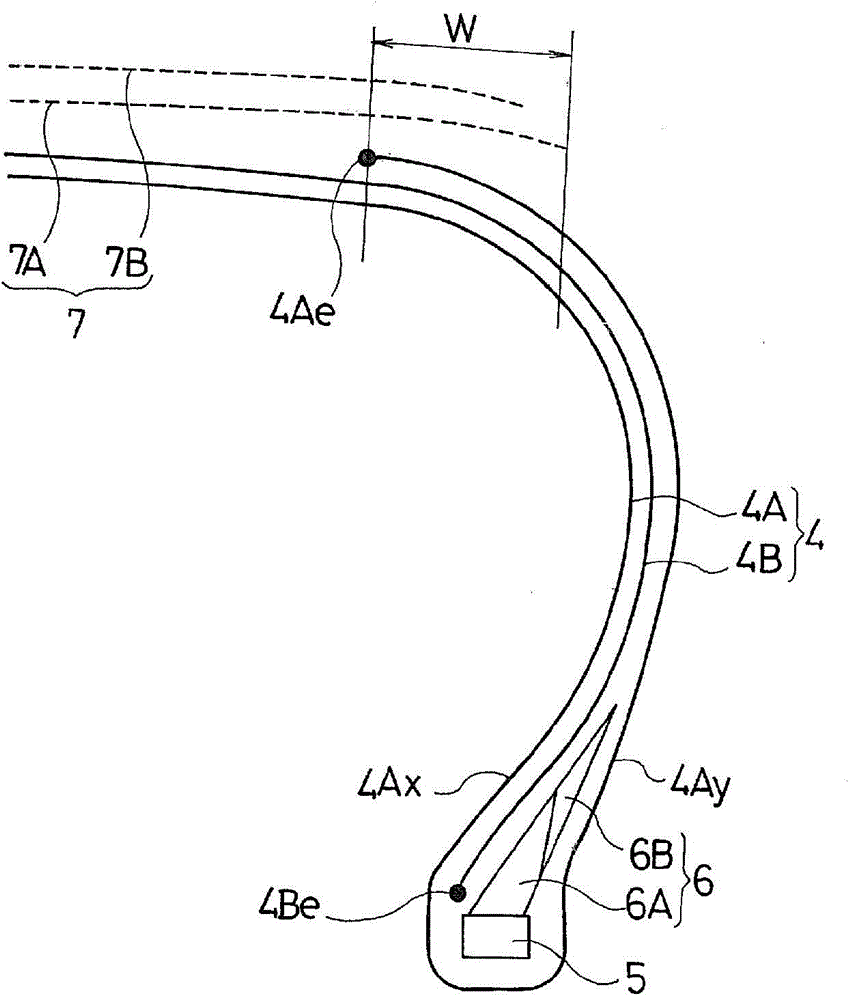

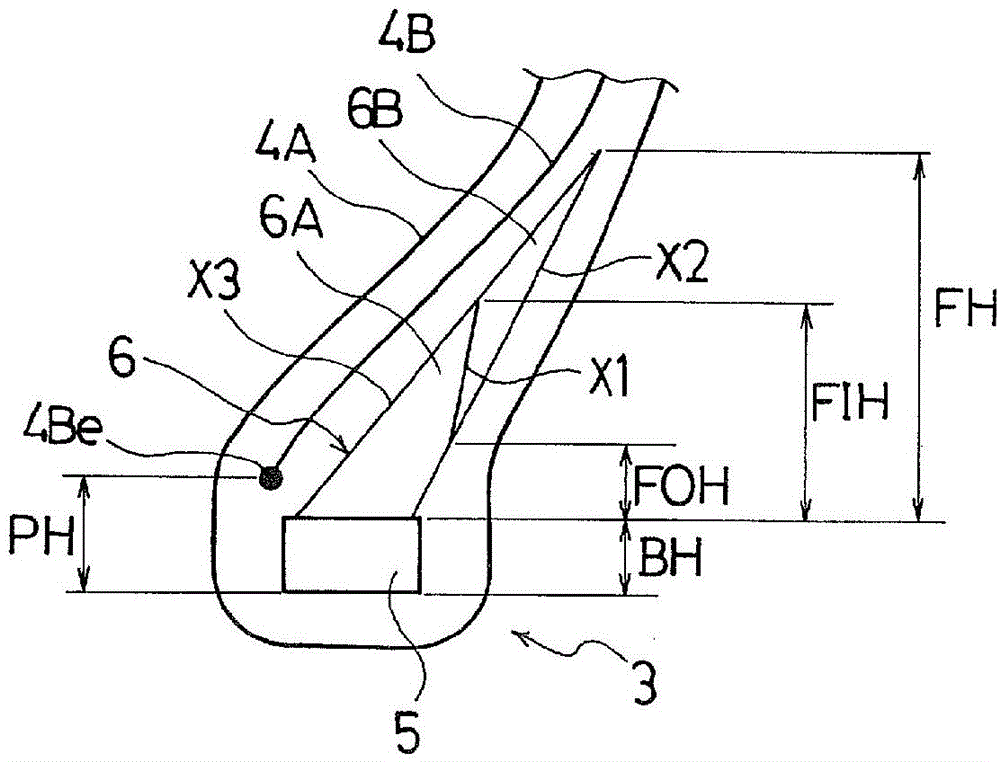

[0060] The tires of Conventional Example, Comparative Examples 1 and 2, and Examples 1 to 7 were produced. These tires are pneumatic tires, wherein the tire size is 225 / 70R16, and multiple layers including a plurality of tires are built between a pair of bead parts. The carcass ply of the body cord has a bead core and a bead filler arranged in each bead portion, and a two-layer belt layer is arranged on the outer peripheral side of the carcass ply, but the structure of the carcass ply is different. same.

[0061] The conventional tire has a structure using three layers of carcass plies (see Figure 6 ), both ends of the inner carcass ply (the first ply and the second ply) are turned back around each bead core, and on the other hand, both ends of the outer carcass ply (the third ply) The sections terminate at each bead section without turning back around each bead core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com