Thermistor, manufacturing method thereof, and film-type thermistor sensor

A technology for thermistors and manufacturing methods, applied to thermistors, resistors, thin film resistors, etc., can solve the problems of no heat resistance, uncertain reliability of nitride-based materials, and inability to ensure heat resistance, etc. , to achieve the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

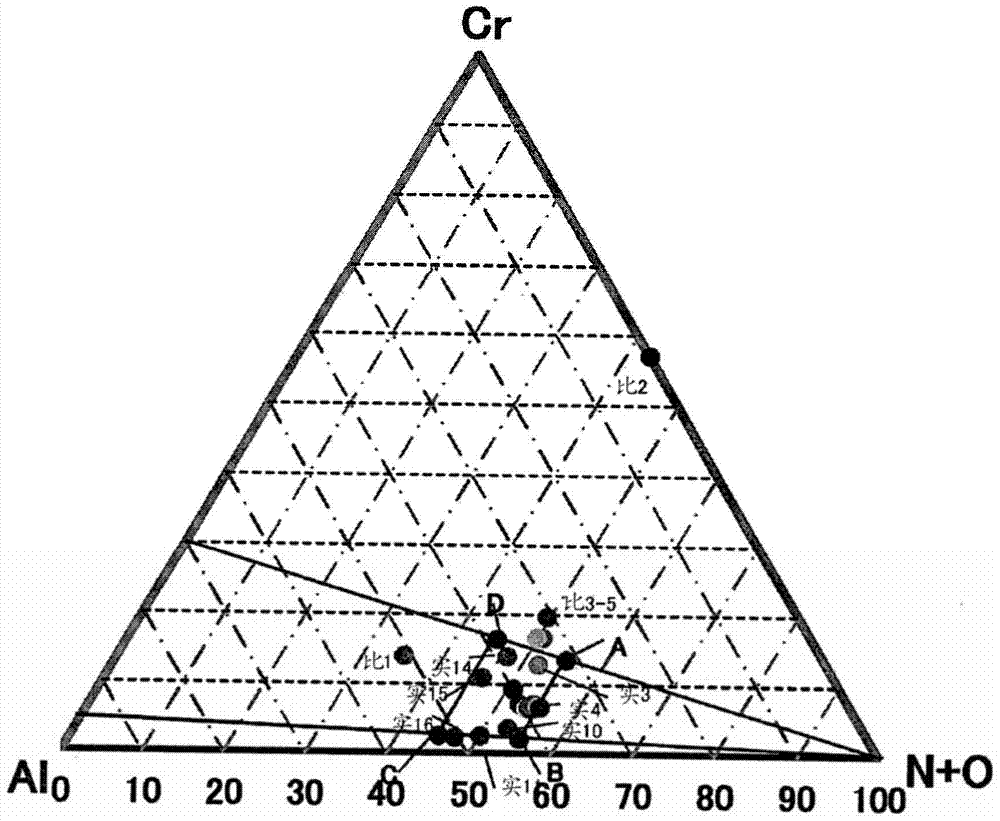

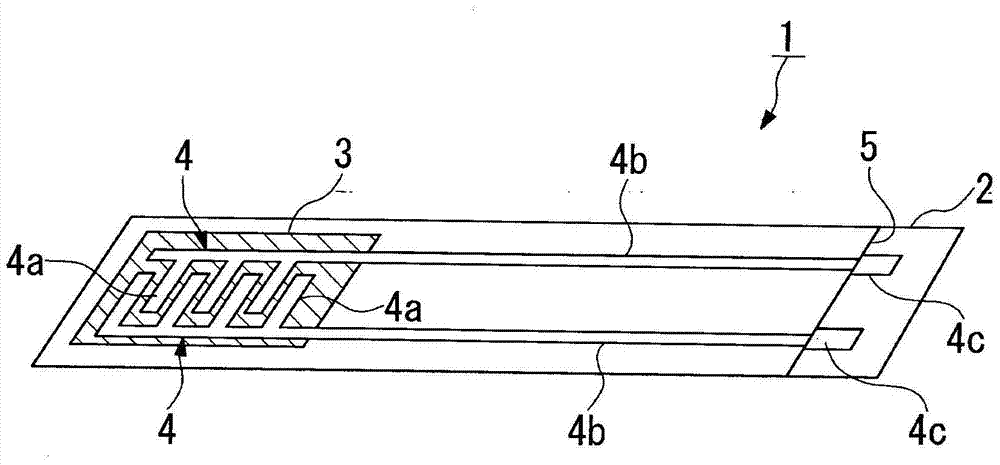

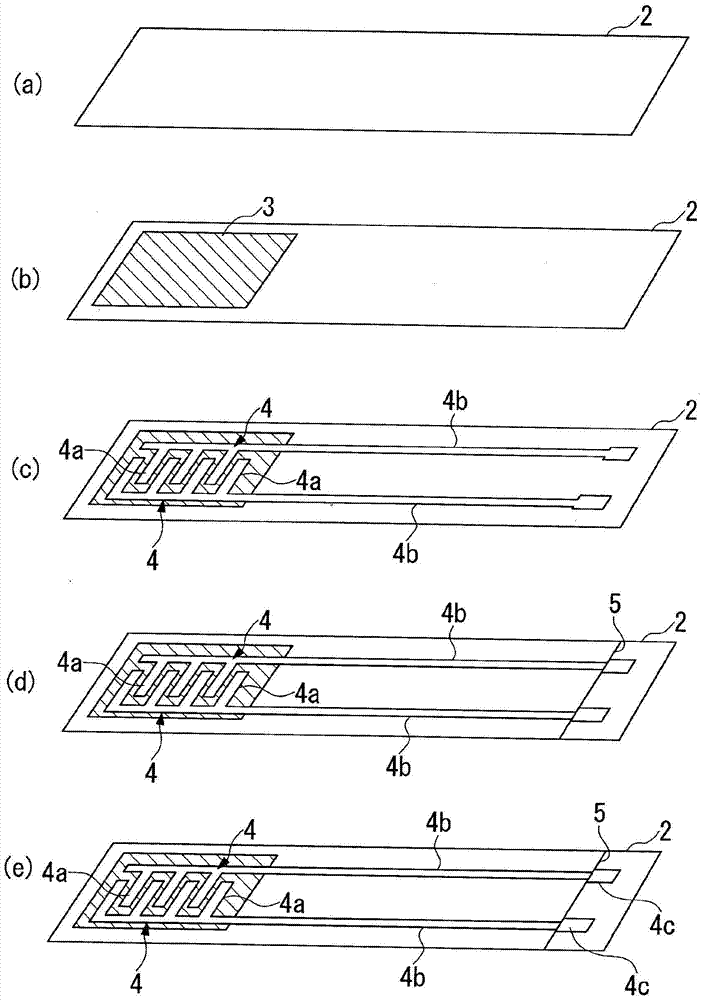

[0078] Next, regarding the metal nitride material for thermistors and its manufacturing method and thin-film thermistor sensor according to the present invention, refer to Figure 4 to Figure 13 , and specifically describe the results of evaluation based on the examples prepared according to the above-mentioned embodiment.

[0079]

[0080] As examples and comparative examples of the present invention, the following Figure 4 Element 121 is shown for film evaluation.

[0081] First, by reactive sputtering, Cr-Al alloy targets with various composition ratios were used to form Si substrates S with thermally oxidized Si wafers with a thickness of 500 nm, as shown in Table 1 and Table 2. Thin film thermistor part 3 of metal nitride material for thermistor formed in various composition ratios. The sputtering condition at this time is the ultimate vacuum degree: 5×10 -6 Pa, sputtering pressure: 0.1~1Pa, target input power (output power): 100~500W, and in the mixed gas atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com