Metal nitride material for thermistor, manufacturing method thereof, and thin film type thermistor sensor

A technology of thermistor and manufacturing method, which is applied in the thermistor, metal material coating process, resistor, etc., can solve the problems of lack of heat resistance and unclear reliability of nitride-based materials, and achieve high resistance thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

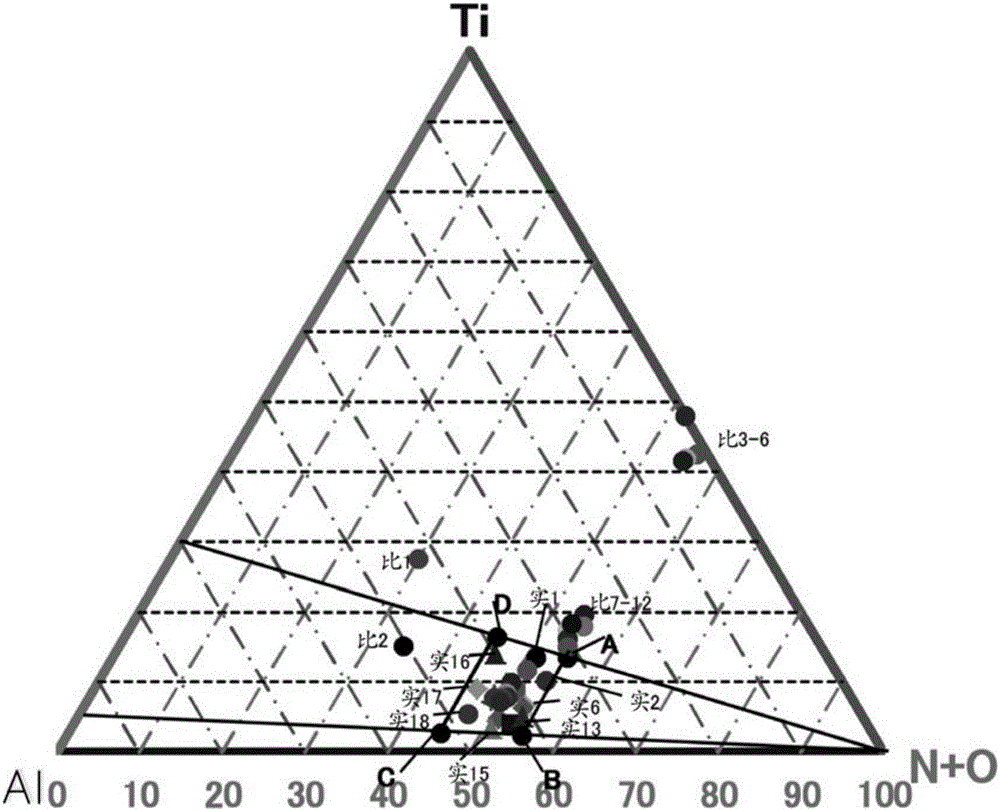

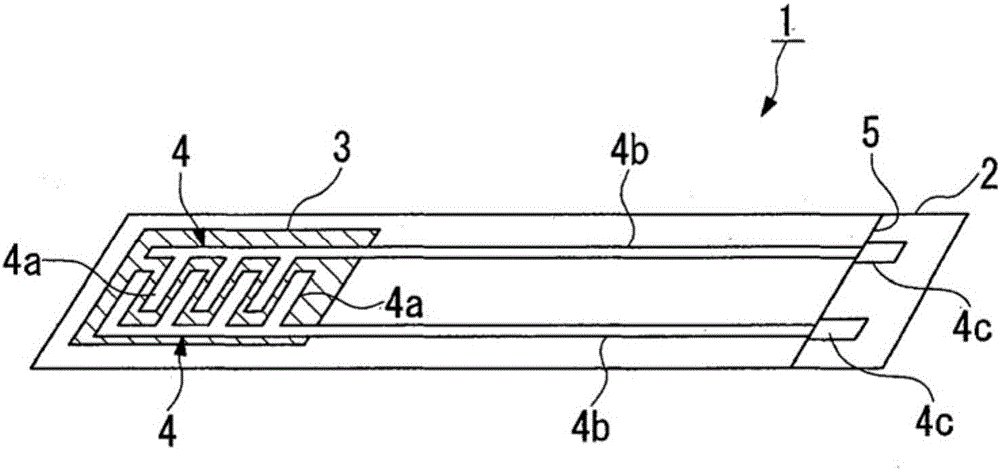

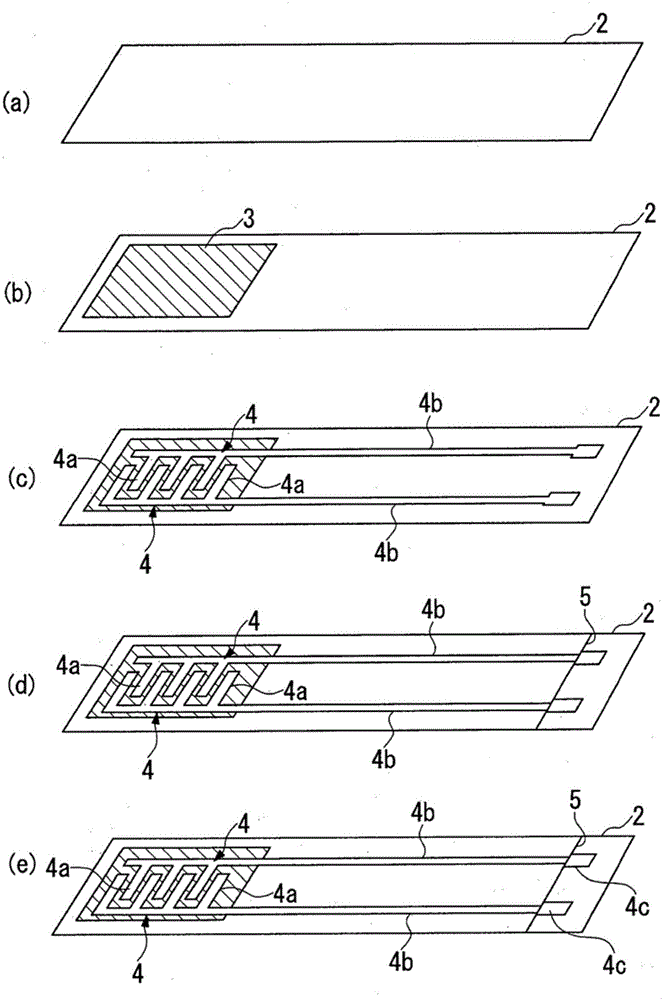

[0047] Next, regarding the metal nitride material for thermistors and its manufacturing method and thin-film thermistor sensor according to the present invention, refer to Figures 4 to 13 , and specifically describe the results of evaluation based on the examples prepared according to the above-mentioned embodiment.

[0048]

[0049] As examples and comparative examples of the present invention, the following Figure 4 Element 21 is shown for film evaluation. First, by reactive sputtering, Ti-Al alloy targets with various composition ratios were used to form Si wafers with thermally oxidized films to form Si substrates S, as shown in Table 1 and Table 2, with a thickness of 500 nm. Thin film thermistor part 3 of metal nitride material for thermistor formed in various composition ratios. The sputtering condition at this time is the ultimate vacuum degree: 5×10 -6 Pa, sputtering pressure: 0.1~1Pa, target input power (output): 100~500W, and in the mixed gas atmosphere of Ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com