Metal nitride material for thermistor, manufacturing method thereof, and thin film type thermistor sensor

A technology for thermistors and manufacturing methods, applied in thermistors, coated resistance materials, resistors, etc., can solve the problems of unclear thermal reliability and no heat resistance of nitride-based materials, and achieve good B Constant, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

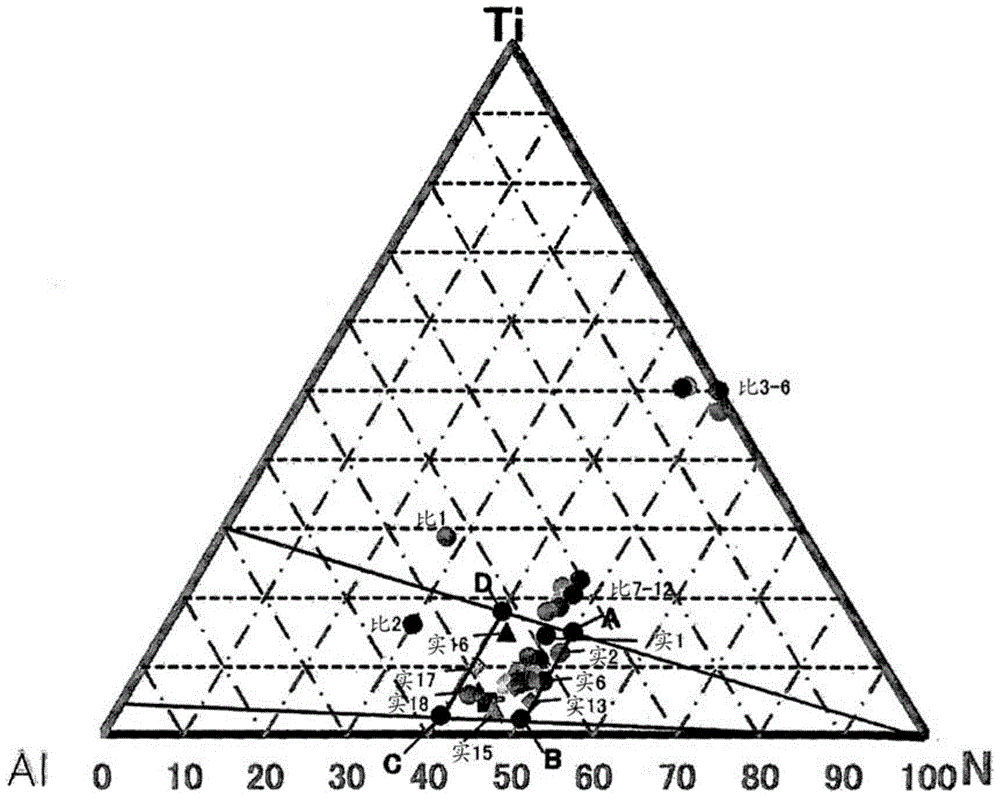

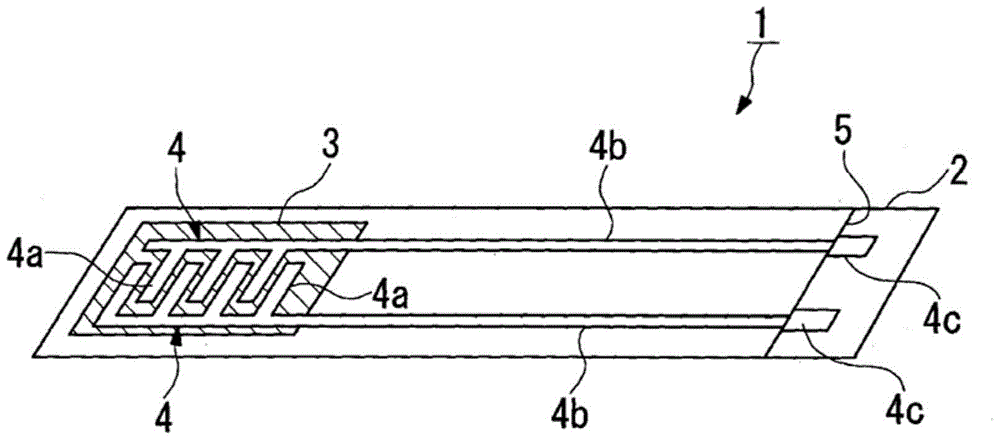

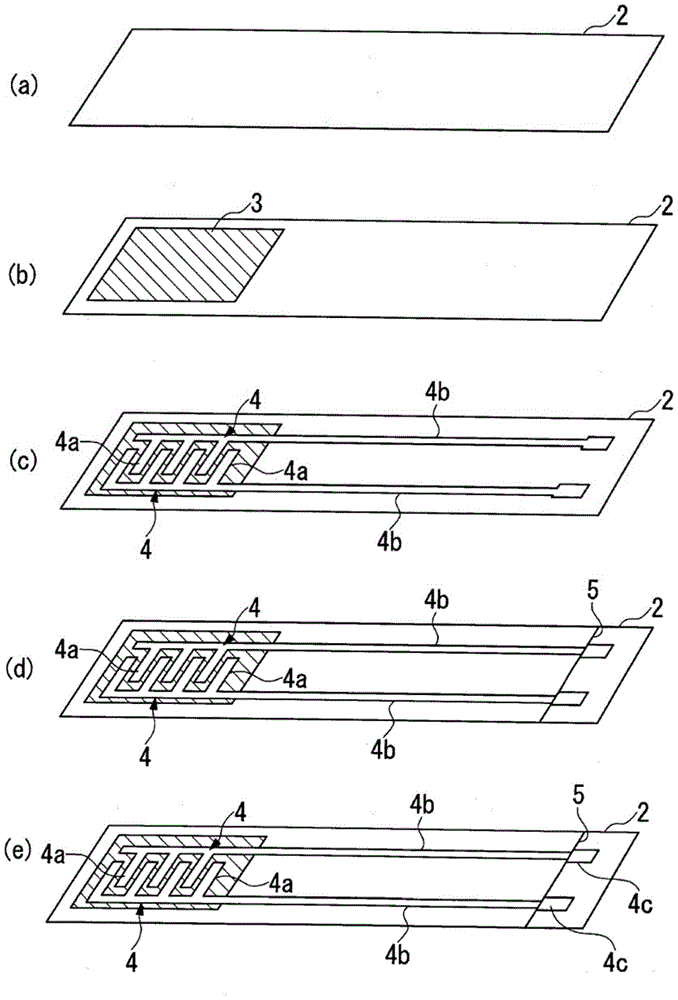

[0046] Next, regarding the metal nitride material for thermistors and its manufacturing method and thin-film thermistor sensor according to the present invention, refer to Figures 4 to 12 , and specifically describe the results of evaluation based on the examples prepared according to the above-mentioned embodiment.

[0047]

[0048] As examples and comparative examples of the present invention, the following Figure 4Element 21 is shown for film evaluation. First, Ti-Al alloy targets with various composition ratios were used to form Si wafers with thermally oxidized films serving as Si substrates S with various compositions shown in Table 1 with a thickness of 500 nm by the reactive sputtering method. The thin film thermistor part 3 of the thermistor is formed using a metal nitride material. The sputtering condition at this time is the ultimate vacuum degree: 5×10 -6 Pa, sputtering pressure: 0.1 to 1Pa, target input power (output): 100 to 500W, and produced in a mixed g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com