Plant factory system

A technology for factories and plants, applied in the field of plant soilless cultivation, can solve the problems of reducing the absorption of nutrient solution, increasing the structural weight of the cultivation tank, and lacking a filtration system, and achieves the effects of improving growth efficiency, enriching cultivars, and improving transpiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

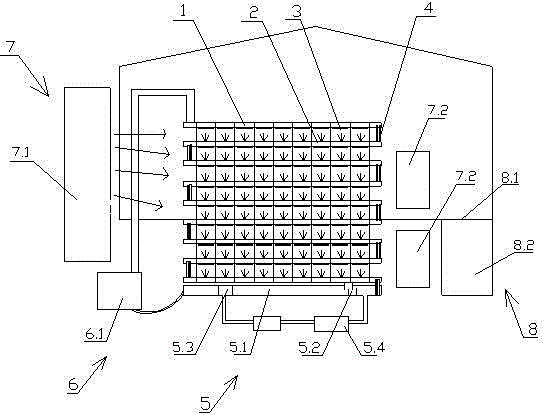

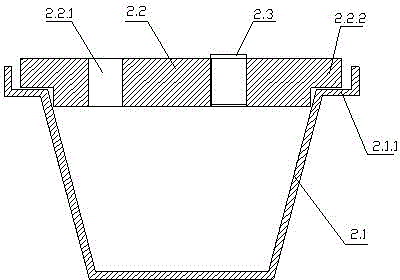

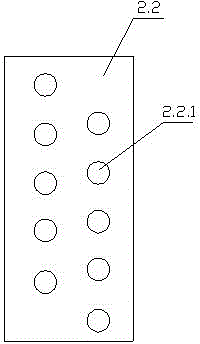

[0040] See Figure 1~10 , The present invention relates to a plant factory system. The plant factory system includes a plurality of cultivation planting racks arranged in a clean room, and the cultivation planting rack includes a cultivation frame 1 arranged in a multi-layer structure, such as figure 1 The illustrated cultivation frame 1 is arranged in a nine-layer structure, and each layer of the cultivation frame 1 is equipped with a trough-type cultivation structure 2 which includes a cultivation trough 2.1 with a trapezoidal cross-section. 2.1 Steps 2.1.1 are provided on both sides of the top opening, the cultivation plate 2.2 is provided with shoulders 2.2.2 resting on the step surface of the step 2.1.1 on both sides of the cultivation plate 2.2, and the cultivation plate 2.2 is provided with multiple planting holes 2.2.1, the planting hole 2.2.1 is embedded with a planting basket 2.3, the planting basket 2.3 is stuffed with a sponge 2.4, and the top of the sponge 2.4 is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com