Method for preventing collision of pre-straightening steel plate and subsequent equipment, and steel plate head warping detection apparatus

A detection device and pre-straightening technology, which is applied in the direction of length measuring device, rolling mill control device, metal processing equipment, etc., can solve the problems of the main drive of the pre-straightening machine, the safety disconnection of the main drive, the poor reliability of the detection signal, and equipment failure. Achieve the effect of avoiding the problem of steel plate warping, reducing the probability of missed judgment, and ensuring equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

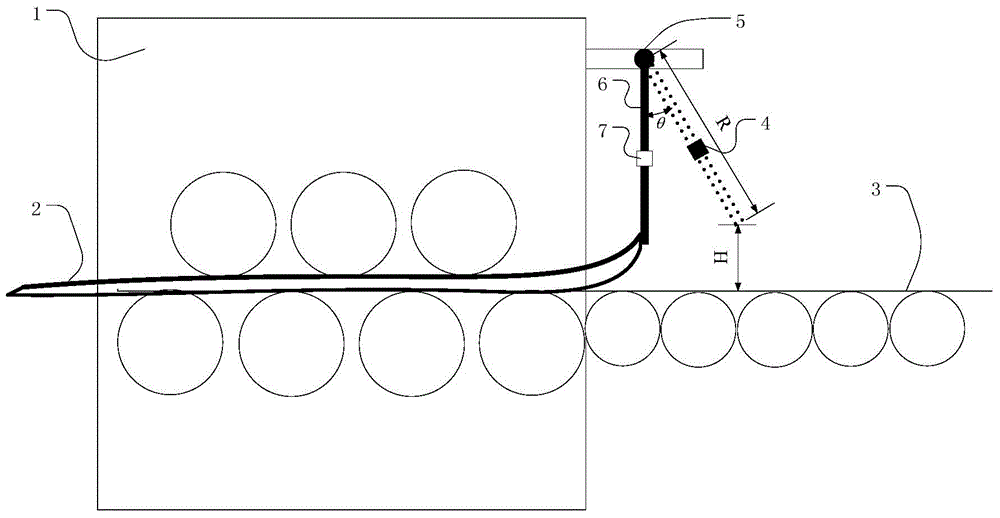

[0023] The method for preventing the pre-straightening steel plate from colliding with the subsequent equipment and the steel plate warping detection device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but they are not intended to limit the present invention.

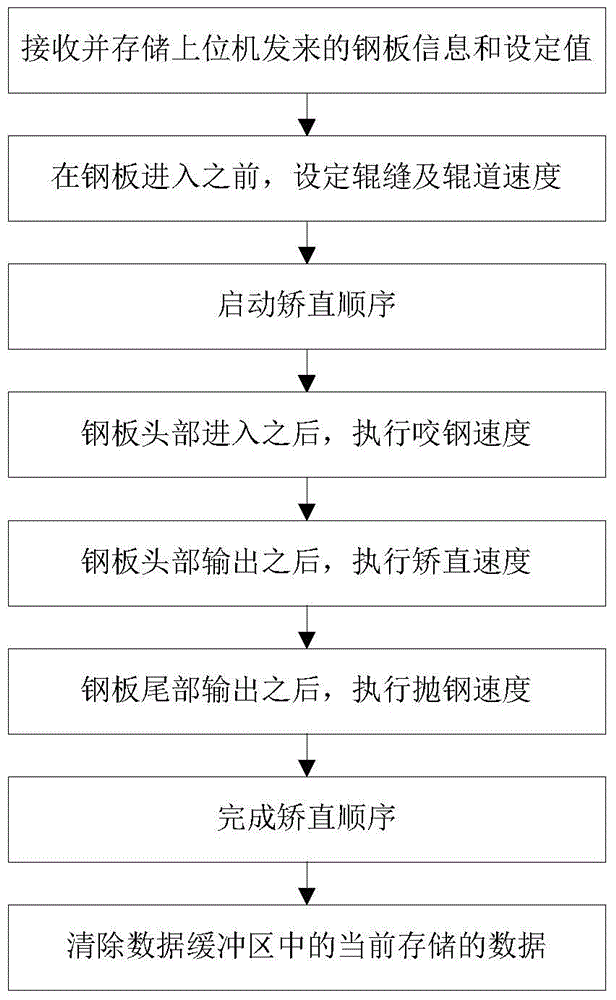

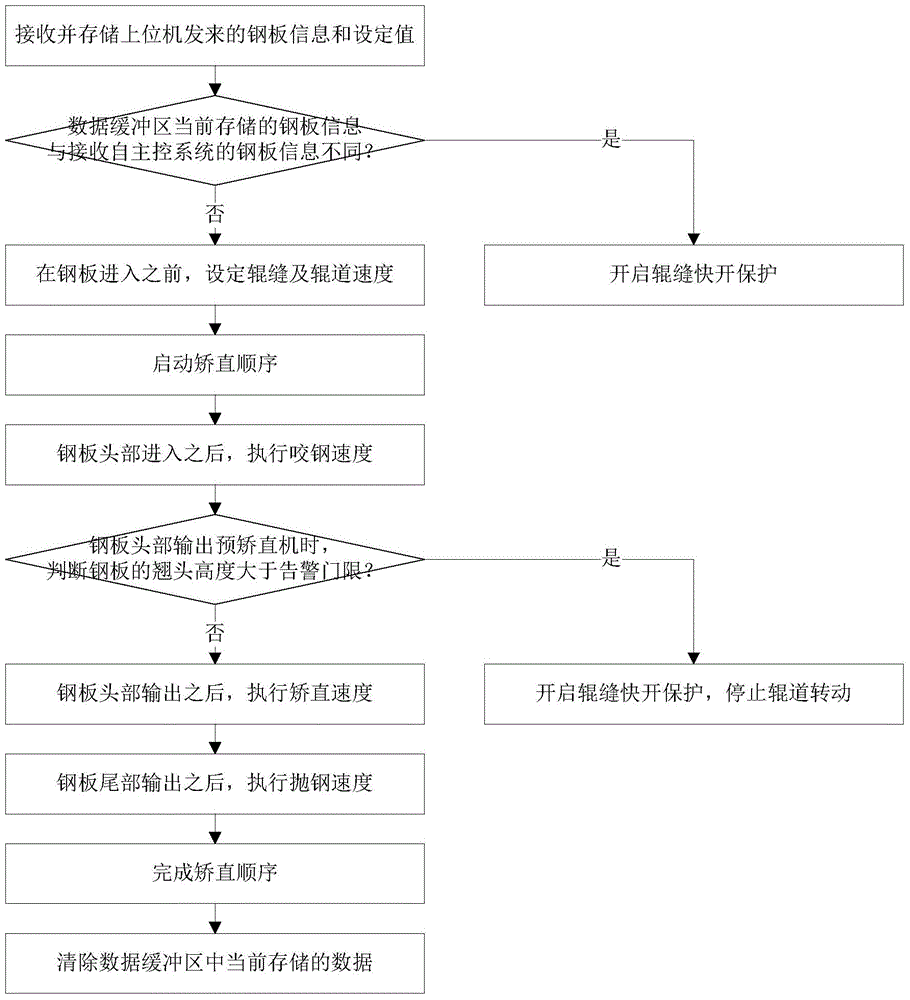

[0024] Such as figure 2 Shown is a flow chart of a preferred embodiment of the method for preventing pre-straightened steel plates from colliding with subsequent equipment in the present invention. The pre-leveler receives the steel plate information and setting values sent by the host computer and stores them in the data buffer of the pre-leveler; when it detects that there is a steel plate to be processed on the roller table at the entrance of the pre-leveler, the steel plate enters the pre-leveler Before the straightening machine, compare the steel plate information currently stored in the data buffer of the pre-leveler w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com