Polishing method and polishing apparatus

一种研磨方法、研磨装置的技术,应用在研磨装置、研磨机床、磨削机床的部件等方向,能够解决无法判断再研磨、无法获得错误晶片膜厚测定数据等问题,达到避免废弃处置的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

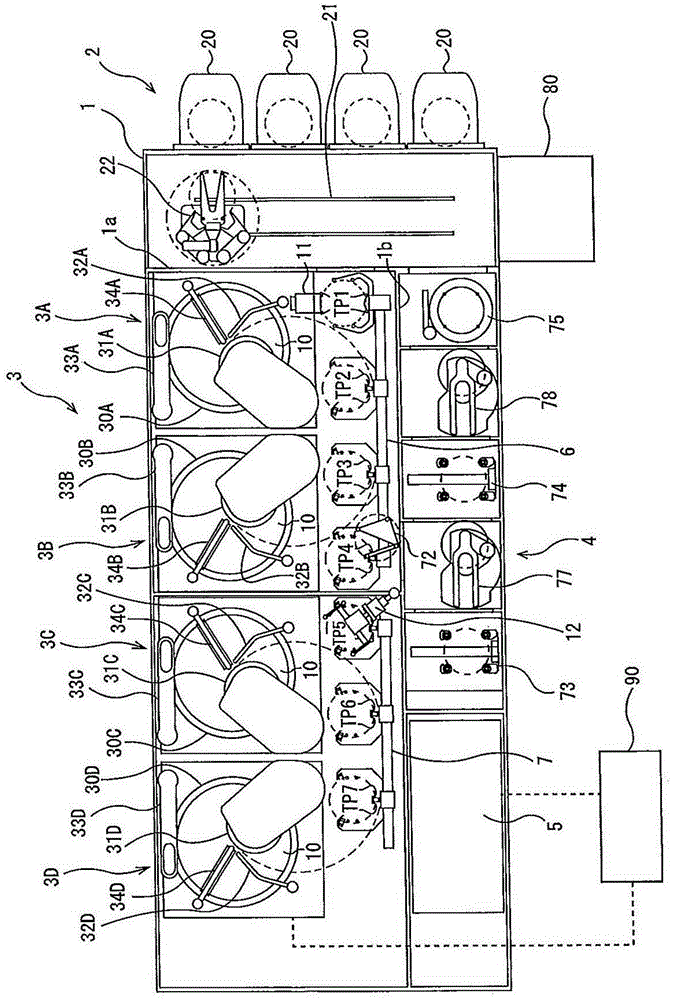

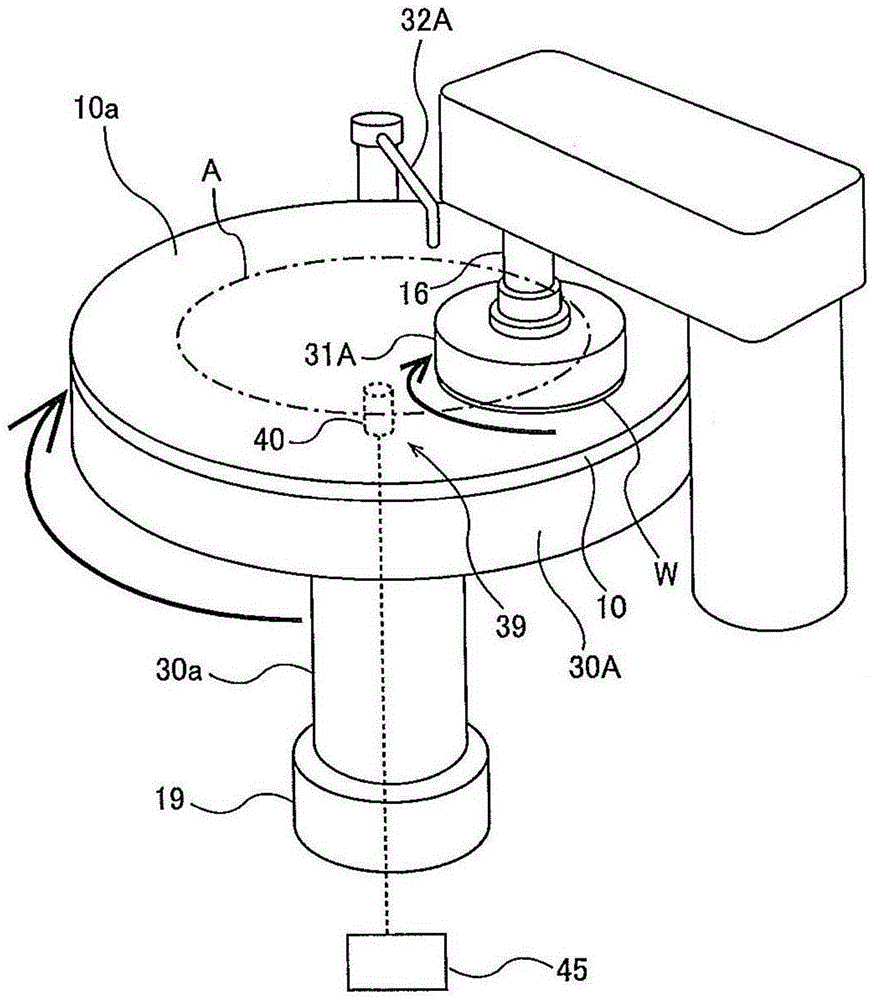

[0056] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a figure which shows the grinding|polishing apparatus which concerns on embodiment of this invention. Such as figure 1 As shown, the grinding device has a substantially rectangular housing 1, and the inside of the housing 1 is divided into a loading / unloading unit 2, a grinding unit 3, and a cleaning unit 4 by partition walls 1a, 1b. The polishing apparatus has an operation control unit 5 that controls wafer processing operations.

[0057] The loading / unloading section 2 has a front loading section 20 on which a substrate cassette storing a plurality of wafers (substrates) is placed. On the loading / unloading section 2, a traveling mechanism 21 is laid along the arrangement of the front loading section 20, and a transfer robot (loader) 22 is provided on the traveling mechanism 21 movable in the direction in which the substrate cassettes are arranged....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com