Guiding rule for quick and precise locating

A precise positioning and ruler-based technology, which is applied in the direction of multi-purpose machinery, wood processing equipment, sawing components, etc., can solve the problems of slow size adjustment, inaccurate size values, and unsuitable for large-sized rulers, etc., to achieve work Improved efficiency and work quality, precise dimensional positioning, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, three specific embodiments of the present invention will be described in detail in conjunction with the above-mentioned drawings.

[0044] Option One:

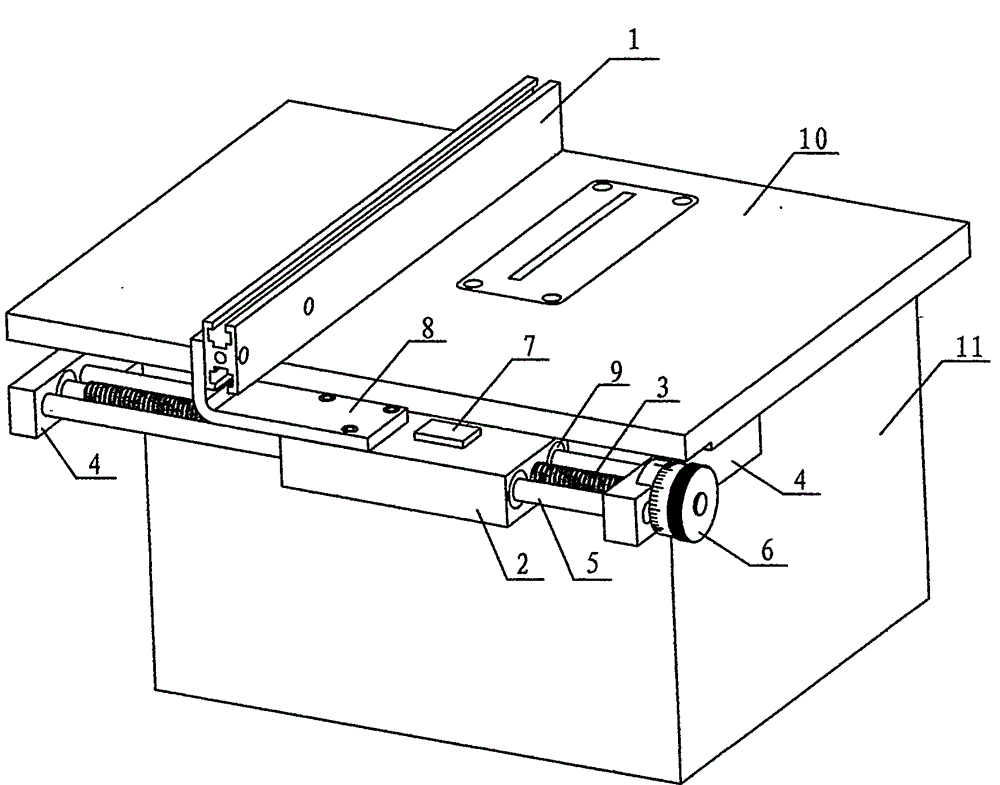

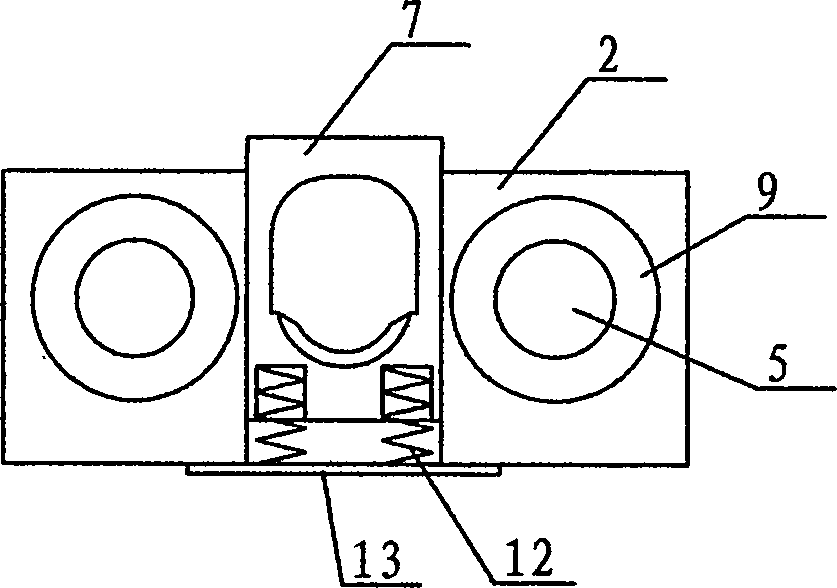

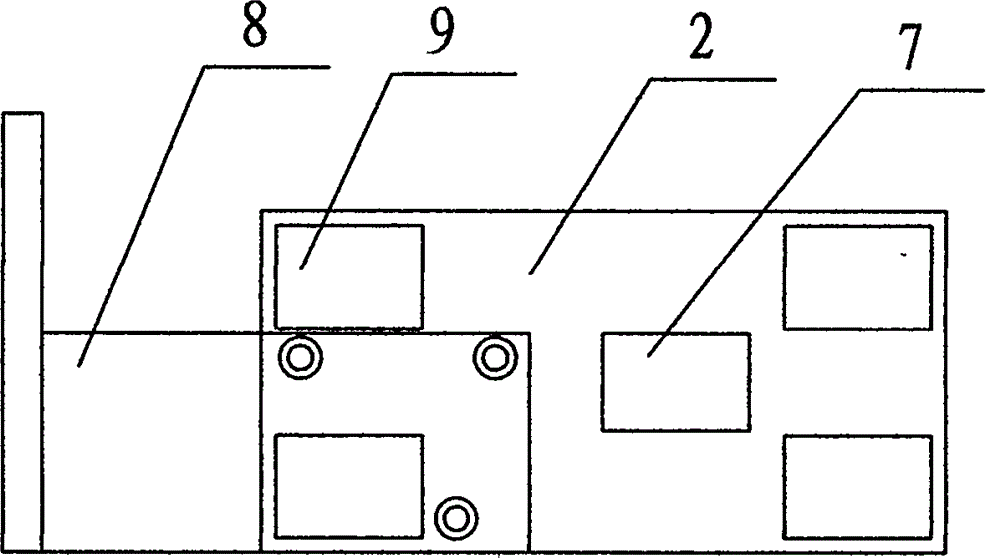

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 as shown, figure 1Drawing with the circular saw cutting machine as the prototype, the ruler (1) in the above figure is usually made of aluminum alloy profile, and the ruler (1) is fixed on the top of the sliding table (2) through the connecting plate (8) with screws, and the sliding table ( 2) Two linear bearings (9) are installed on both sides, and there is a square vertical through hole in the middle of the sliding table (2) for installing the half nut (7), and the half nut (7) is installed in it and only up and down Sliding, the half nut (7) side wall and the hole wall are sliding fit, and the half nut is a kind of nut with partial thread (14). The optical axis (5) and the screw mandrel (3) are installed between the end plates (4) on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com