A paper flower-shaped maker that is symmetrical around the axis

A maker, flower-shaped technology, applied in cardboard items, machining/deformation, etc., can solve problems such as low work efficiency and achieve the effect of saving tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

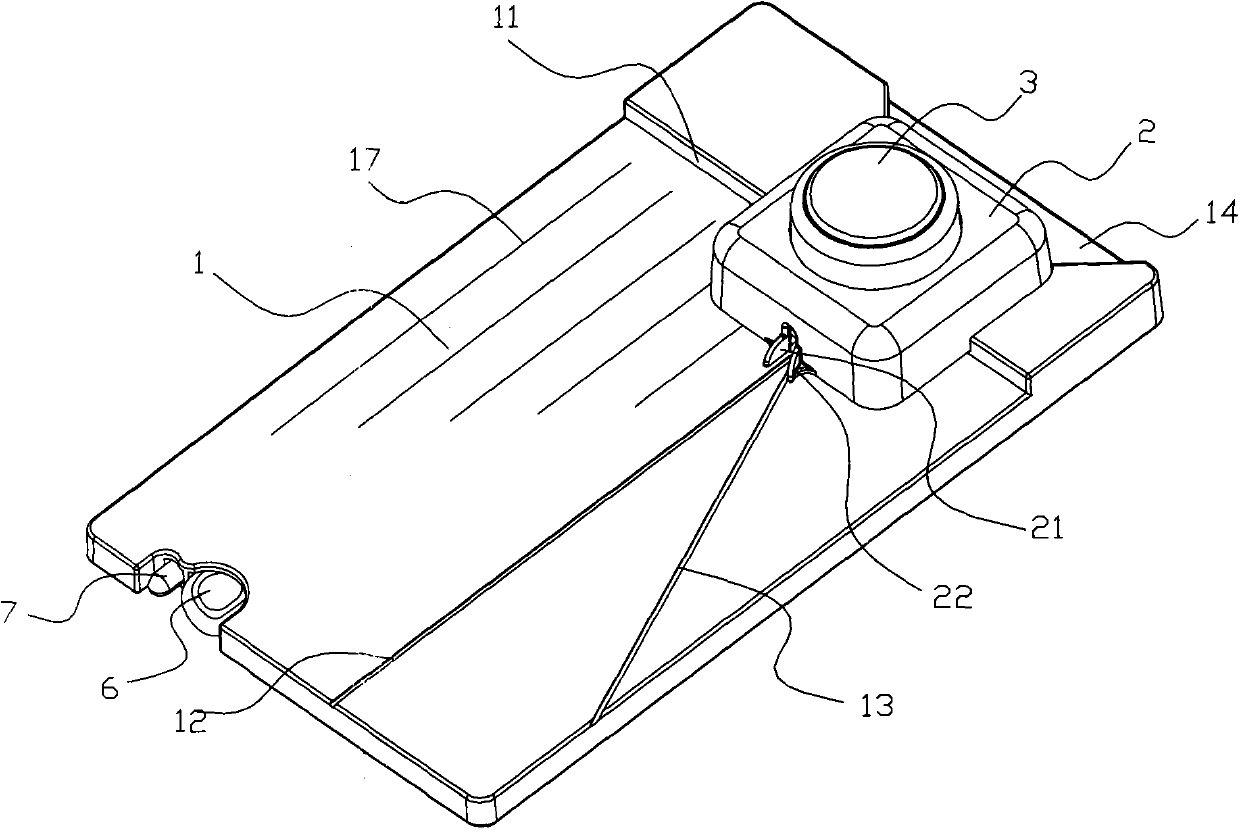

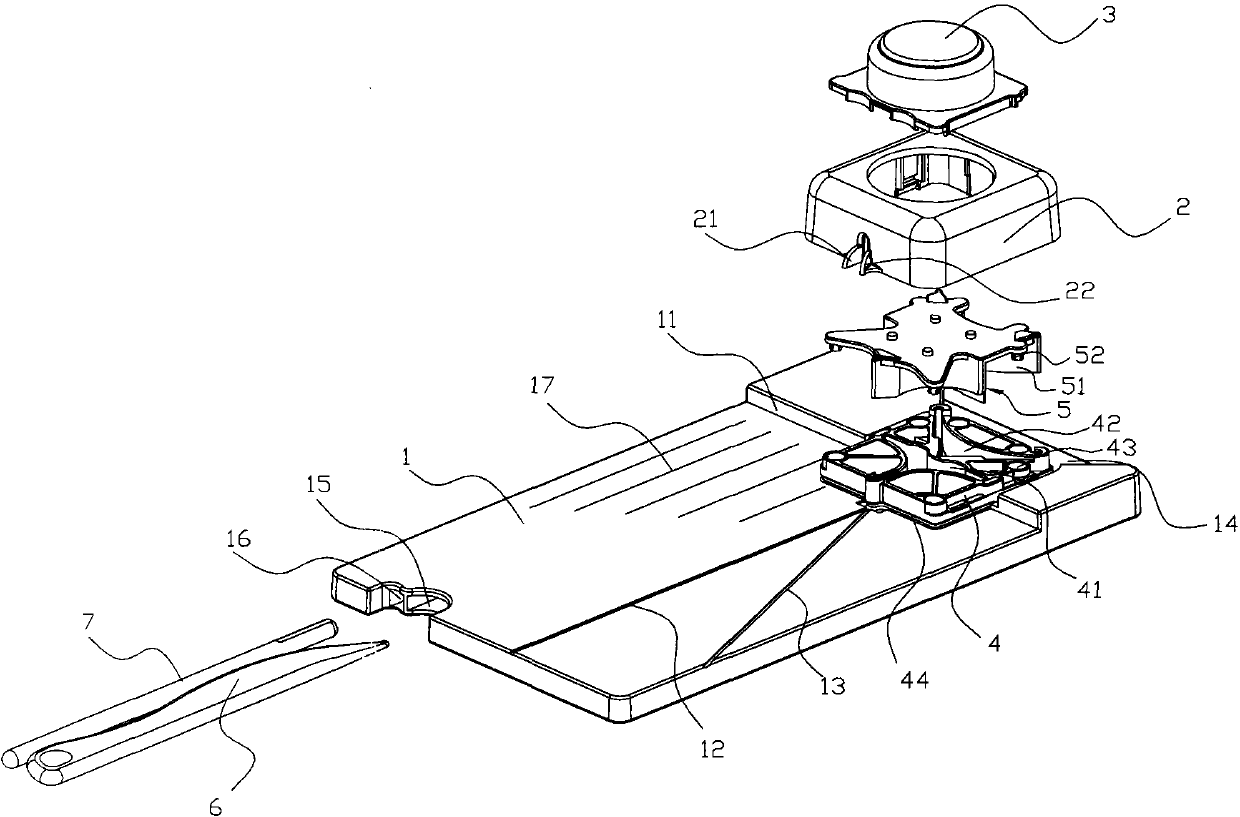

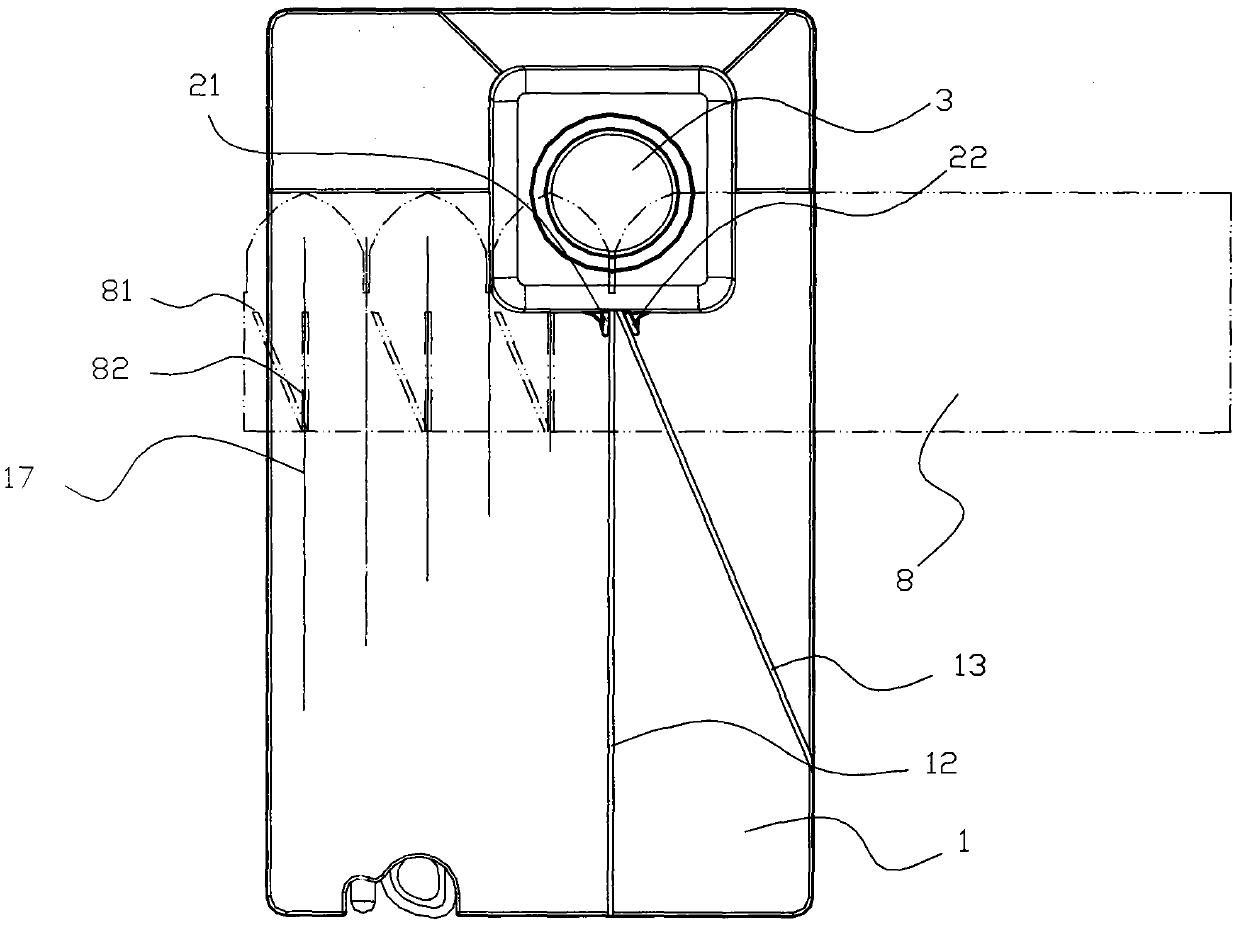

[0029] A kind of paper flower-shaped maker that is symmetrical around the axis of the present invention, such as figure 1 , 2 , 3, and 4, including a scribing board 1 and a cutter; the scribing board 1 has a raised reference edge 11 on its surface, and the flower-shaped paper 8 leans against the reference edge ( image 3 ); the surface of the marking board 1 is provided with a folded groove 12 perpendicular to the reference side and an angled groove 13 maintaining an angle with the folded groove, and the angle between the folded groove 13 and the folded groove 12 is a flower shape Petal 81 ( Figure 4 ) is half of the average angle corresponding to the number, and the number of petals 81 is eight ( Figure 4 ), the average angle of each petal around the axis is forty-five degrees, the angle between the folded groove 12 and the folded groove 13 is 22.5 degrees, the number of petals can be set according to needs, the folded groove 12 The included angle of the angled groove 13...

Embodiment 2

[0036] Such as Figure 5As shown, the difference between Embodiment 2 and Embodiment 1 is that there are three knuckle grooves 13' provided on the surface of the scribing board 1 (can be set within the range of two to six as required), and can be set according to different The flower shape of the number of petals uses the angled groove 13' corresponding to the included angle, which makes the scribing board have a larger scope of application. The disadvantage of this structure is that the surface of the scribing board is more complicated than the surface of the scribing board in Example 1 and is difficult to identify. Due to the use of multiple knurling grooves, the knurling groove guide block 22 provided on the cutter housing 2 is removed, which lacks the guiding effect on the knives working in the knuckle grooves.

[0037] The present invention can simultaneously complete the processing of flower-shaped creases and flower-shaped edge contours by setting a scribing board and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com