Two-degrees-of-freedom spherical motion platform

A motion platform and degree of freedom technology, applied in the field of mechanical structure, can solve the problems of inability to achieve 360° rotation, limited rotational movement stroke, short maintenance interval, etc., and achieve the effects of low coupling, reduced wear and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

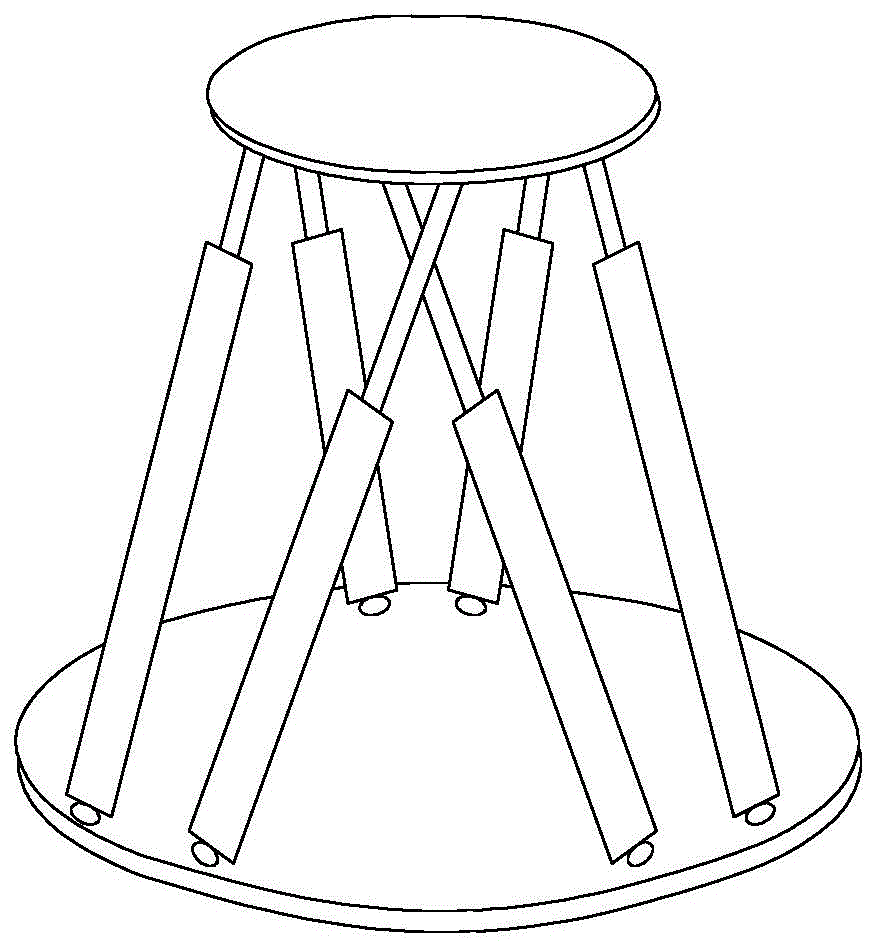

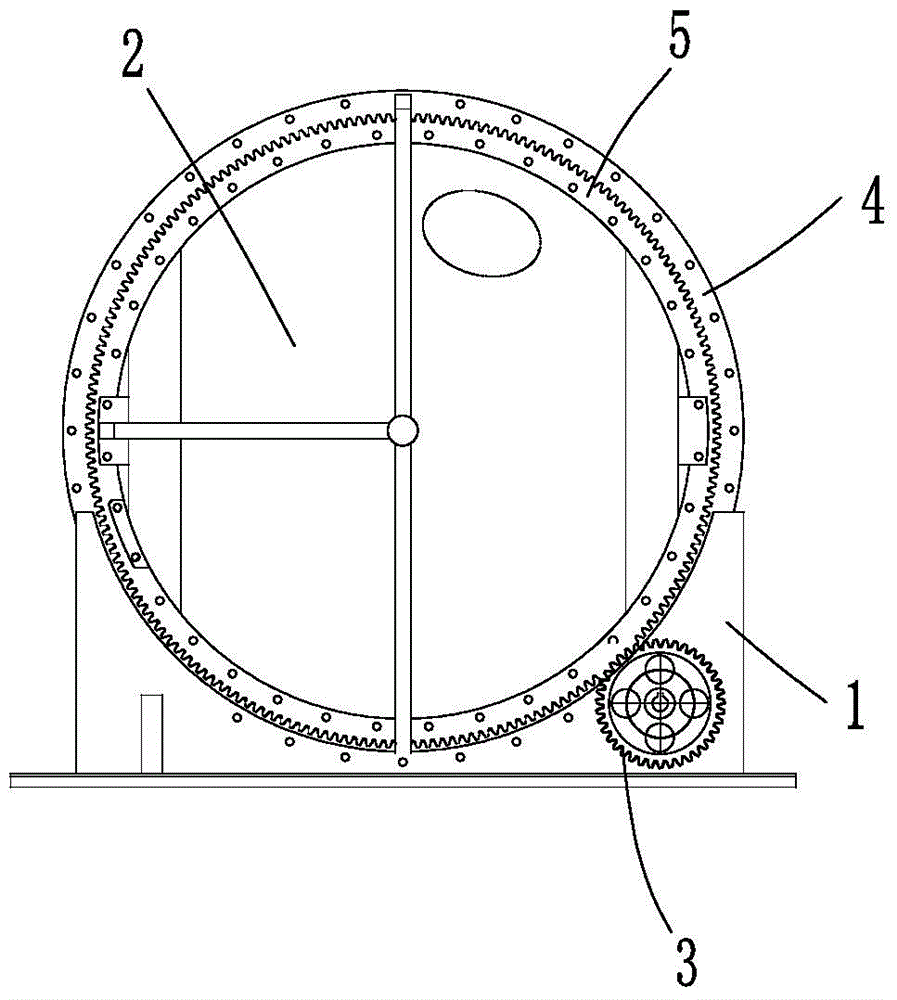

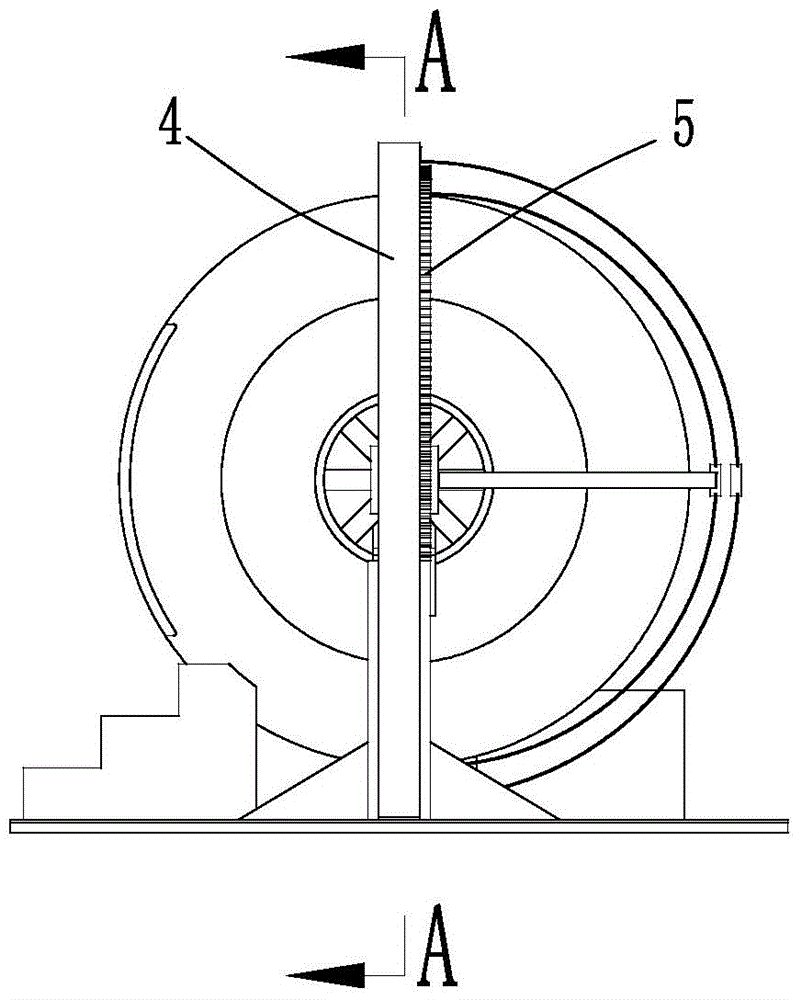

[0016] Such as figure 2 — Figure 6 As shown, a two-degree-of-freedom spherical motion platform is mainly composed of a base 1, a spherical cabin 2, a pitch driving gear 3, an annular outer ring 4, an annular inner ring 5, a rolling connection assembly 6, a bearing 7, a rolling driven wheel 8, Roll driving wheel 9, pitch drive motor (not shown in the figure), roll drive motor (not shown in the figure) etc. are formed.

[0017] The base 1 is used as the mounting seat of the entire two-degree-of-freedom spherical motion platform, and the pitch driving gear 3 is housed in it. The annular outer ring 4 and the annular inner ring 5 are arranged coaxially, both of which are annular parts, and jointly form a rotary support body as a rotary support structure of the spherical cabin 2 . The annular outer ring 4 is fixedly installed on the base 1, and the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com