Cotton collector for reinforcing three-dimensional control of fiber strand

A cotton collector and three-dimensional technology, applied in the field of cotton collectors, can solve the problems of low yarn quality, long jaw distance, reduced production efficiency of enterprises, etc., and achieve convenient operation, simple structure, spinning efficiency and yarn forming efficiency. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

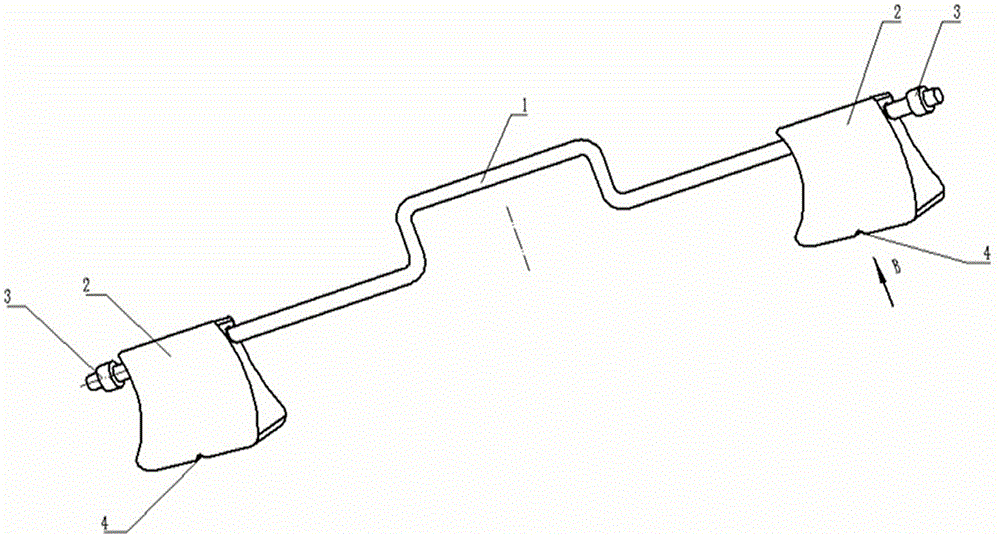

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

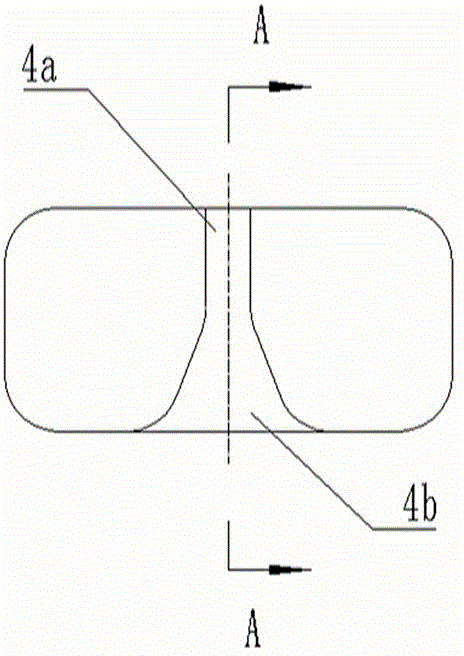

[0012] Such as Figure 1 to Figure 3 As shown, a cotton collector for strengthening the three-dimensional control of whiskers in the present invention includes a "π"-shaped support rod 1, and the two ends of the "π"-shaped support rod 1 are mirror-imaged with solid cotton collector blocks 2, so that The bottom of the solid cotton collector block 2 is respectively provided with a guide groove 4; the "π" shaped support rod 1 on the outer side of the solid cotton collector block 2 is respectively provided with a positioning card 3 .

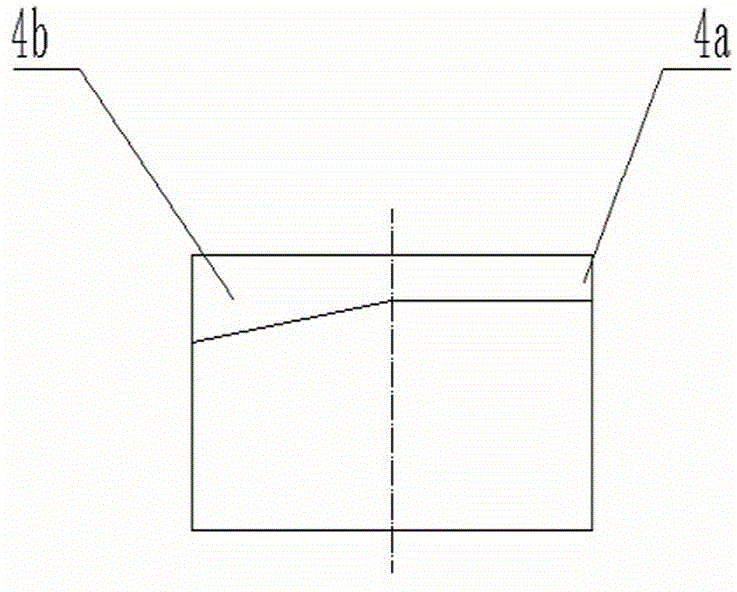

[0013] The guide groove 4 is provided with a semi-trumpet-shaped opening 4b in front and an "n"-shaped opening 4a in the rear.

[0014] The cavities from the semi-trumpet-shaped opening 4b to the "n"-shaped opening 4a are progressively arranged from large to small.

[0015] During operation, the whiskers are exported by the jaws and quickly en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com