Steel pipe combined guide bar

A steel tube and bar technology, which is applied to the bar device field of a high-speed lace warp knitting machine, can solve the problems of consuming manpower and material resources, uneven force, inability to meet demands, etc., and achieves the effect of not easily deformed and compactly connected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

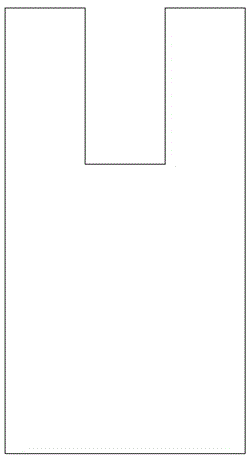

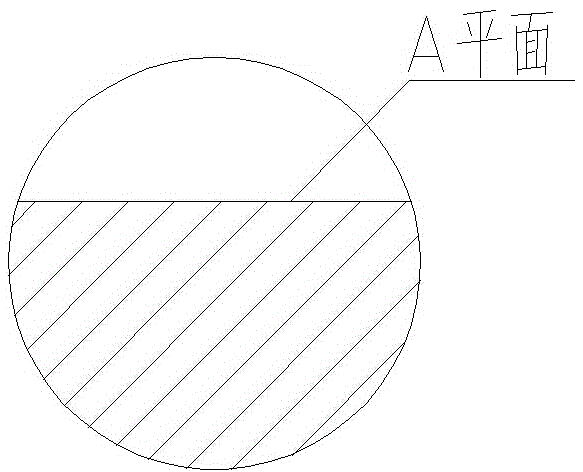

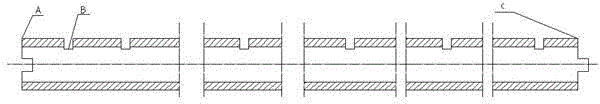

[0021] like Figure 4 Shown is the structural schematic diagram of the steel pipe comb bar, wherein Figure 4 #1 is the hook joint, #2 is the steel wire, #3 is the steel pipe, and #4 is the joint of the steel wire rope. The steel pipe #3 is set on the steel wire #4 to form a composite bar, and the length and needle distance of the bar are determined according to the groove distance on the steel pipe and the number of steel pipes. The steel pipe and steel wire are connected by glue. The steel pipe has an outer diameter of 2.0 mm and an inner diameter of 1.36 mm. The diameter of the steel wire matches the inner diameter of the steel pipe.

[0022] Figure 5 Yes Figure 4 The enlarged schematic diagram of I in the Figure 4 It can be seen that the needle distance is 2.117, that is, 24 needle distances 2, the needle distance from B to C is an even multiple of 2 needle distances, all even needle distances can be arranged, and different numbers of steel pipes are used to deter...

Embodiment 2

[0024] The stitch distance from A to B is 1.058, that is, one stitch length, and one stitch length is added to the even number stitch length to form an odd number stitch length. Any stitch length can then be obtained with any mating needle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com