A Predictive Control Method of Turbogenerator Main Steam Valve Opening Based on Nonlinear Disturbance Observer

A turbogenerator and disturbance observer technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as lack of robustness to parameter and model changes, non-matching uncertainty powerlessness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0106] Embodiment (1) Realize the accuracy and rapidity of turbine generator power angle tracking.

Embodiment approach ( 1

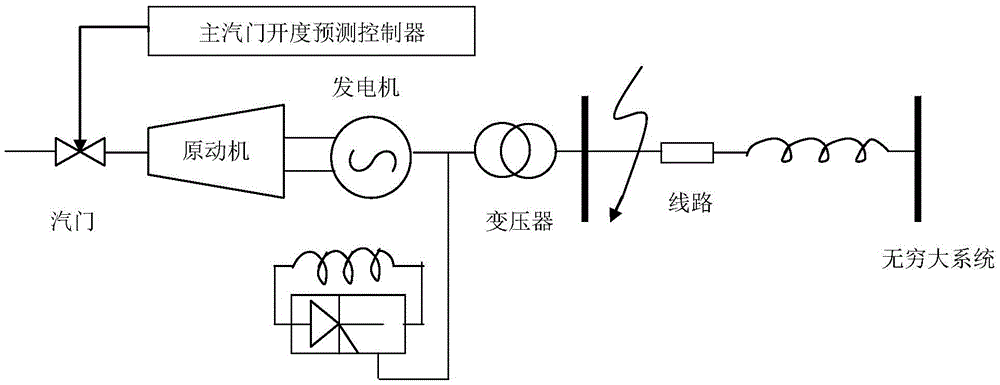

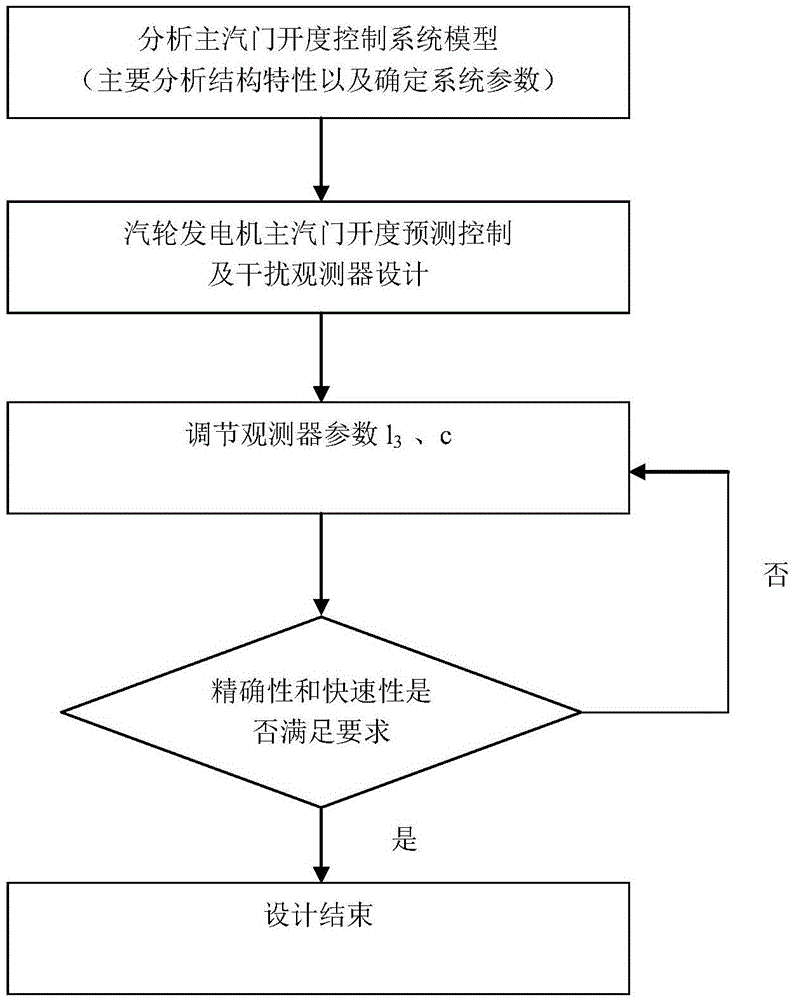

[0108] Step 1: Analysis and modeling of turbogenerator main steam valve opening control system

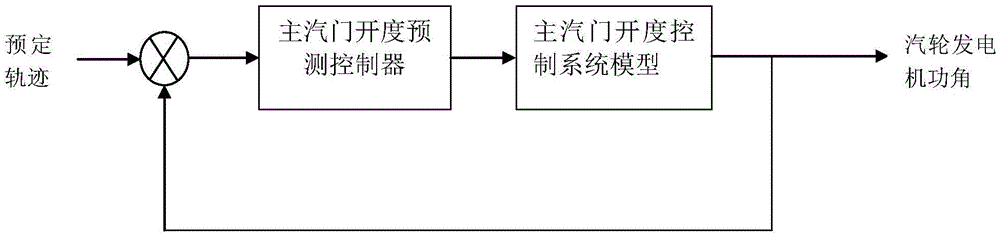

[0109] The closed-loop control system adopts a negative feedback control structure, and the output is the power angle of the turbogenerator. The designed closed-loop control system mainly includes two parts: the controller link and the system model, and its structural layout is shown in figure 2 shown.

[0110] The main valve opening control system model is described as follows:

[0111] δ · = ω - ω 0 ω · = - D H ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com