Solar assisted ejector synergized steam compression type heat pump circulating system and method

An auxiliary ejector and vapor compression technology, which is applied in the field of heat pumps, can solve the problems of complex equipment, small ejector working pressure difference, and low ejector efficiency, and achieve the effects of simple structure, promoting development, and improving steam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

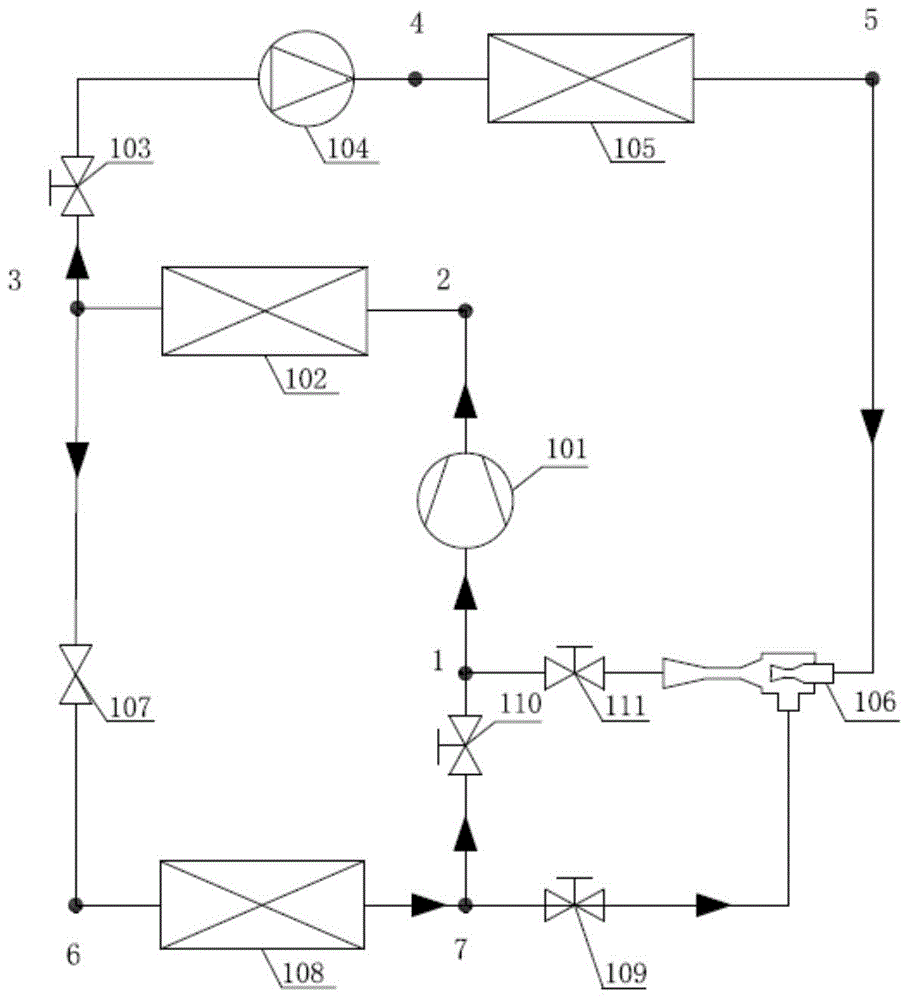

[0015] As shown in the accompanying drawings, the present invention is a vapor compression heat pump cycle system with solar assisted ejector efficiency, comprising a connected compressor 101 and a condenser 102, the outlet of the condenser 102 is divided into two paths, one path After the first cut-off valve 103 is connected with the inlet of the booster pump 104, the outlet of the booster pump 104 is connected with the inlet of the solar collector / generator 105, and the outlet of the solar collector / generator 105 is connected with the outlet of the injector 106. The inlet of the working fluid is connected; the other is connected with the inlet of the expansion valve 107, and the outlet of the expansion valve 107 is connected with the inlet of the evaporator 108; It is connected with the injection fluid inlet of the ejector 106, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com