Application of transition metal organic zinc complex in trace nitroaromatic pollutant detection

A technology for organic pollutants and nitroaromatics, applied in the field of application of transition metal organozinc complexes in the detection of trace nitroaromatic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

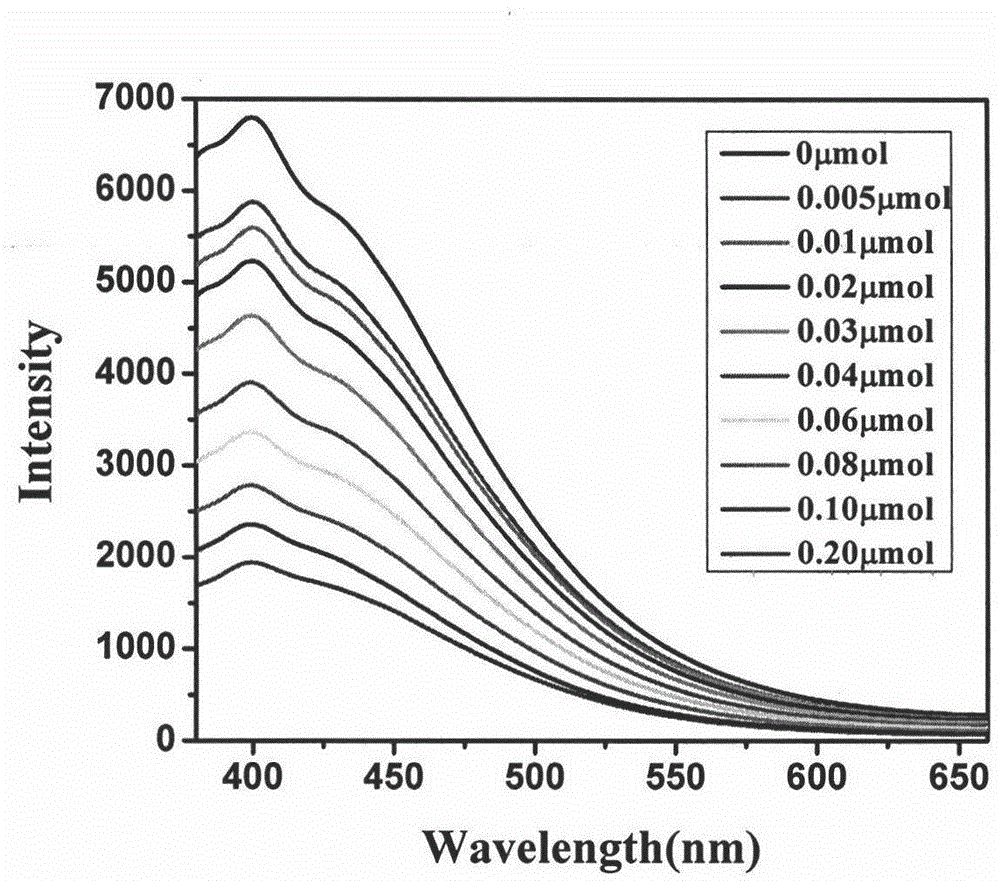

[0023] Embodiment 1 (p-nitrotoluene sensing), the process is as follows:

[0024] First measure the fluorescence intensity F of the sensing material in the absence of p-nitrotoluene 0 , and then add gradient substance amounts of diphenylamine (0 μmol, 0.005 μmol, 0.01 μmol, 0.02 μmol, 0.03 μmol, 0.04 μmol, 0.06 μmol, 0.08 μmol, 0.1 μmol and 0.2 μmol), measure the amount of different substances p-nitrotoluene exists When the fluorescence intensity F of the sensing material is measured, the curve of the fluorescence intensity F changing with the amount of p-nitrotoluene substance is drawn, see figure 1 . The test results show that the fluorescence intensity gradually decreases with the increase of p-nitrotoluene; when the added p-nitrotoluene reaches 0.20μmol, the quenching efficiency reaches 71.46%.

Embodiment 2

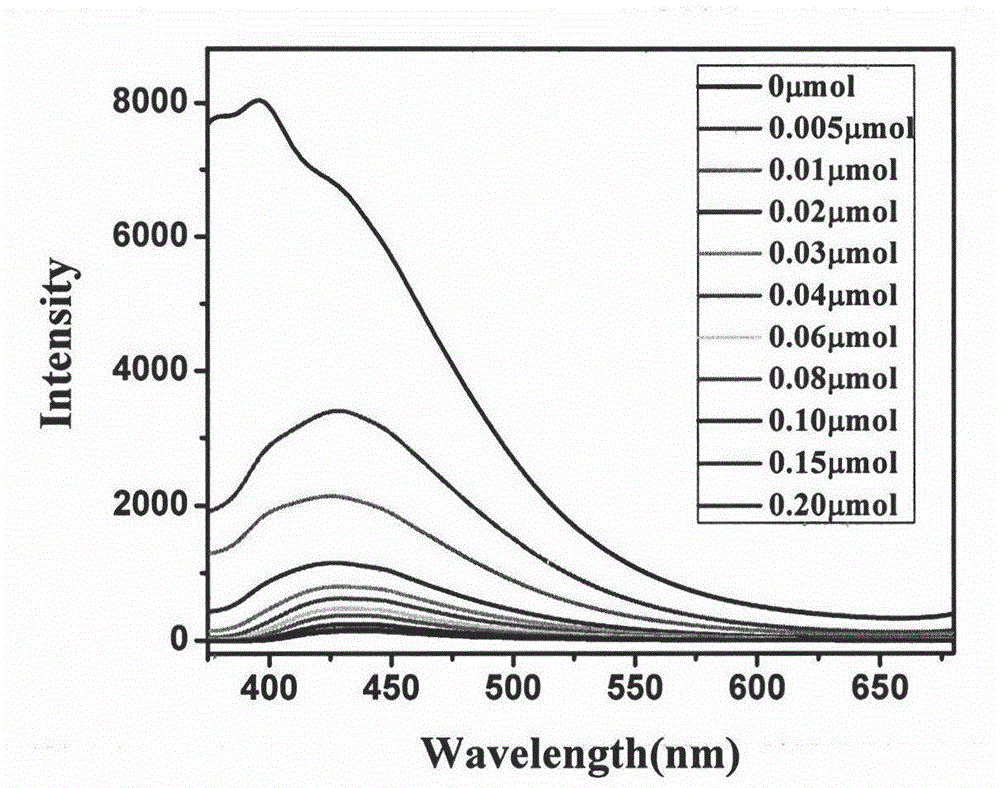

[0025] Embodiment 2 (p-nitroaniline sensing), the process is as follows:

[0026] First measure the fluorescence intensity F of the sensing material in the absence of p-nitroaniline 0 , and then add p-nitroaniline (0 μmol, 0.005 μmol, 0.01 μmol, 0.02 μmol, 0.03 μmol, 0.04 μmol, 0.06 μmol, 0.08 μmol, 0.1 μmol, 0.15 μmol, 0.2 μmol) of the gradient substance amount, and measure the amount of different substances Fluorescence intensity F of the sensing material when p-nitroaniline exists, draw the curve of fluorescence intensity F changing with the amount of p-nitroaniline substance, see figure 2 , the test results show that the fluorescence intensity gradually decreases with the increasing amount of p-nitroaniline substance; when the amount of p-nitroaniline substance added reaches 0.20μmol, the quenching degree reaches 98.76%, which shows that the sensing The sensing effect of the material on p-nitroaniline is very obvious.

Embodiment 3

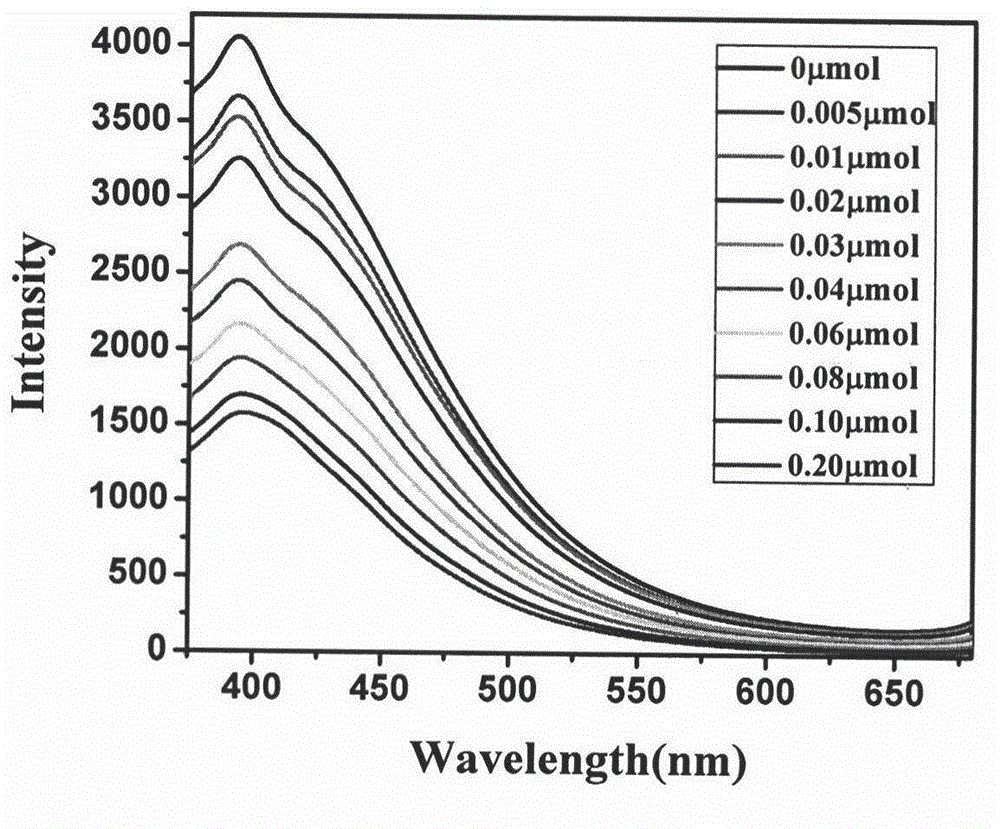

[0027] Embodiment 3 (nitrobenzene sensing), the process is as follows:

[0028] First measure the fluorescence intensity F of the sensing material in the absence of nitrobenzene 0 , and then add gradient substance amounts of nitrobenzene (0 μmol, 0.005 μmol, 0.01 μmol, 0.02 μmol, 0.03 μmol, 0.04 μmol, 0.06 μmol, 0.08 μmol, 0.1 μmol, 0.2 μmol), and measure the amount of nitrobenzene present in different substances When the fluorescence intensity F of the sensing material is measured, the curve of the fluorescence intensity F changing with the amount of nitrobenzene substance is drawn, see image 3 , the test results show that the fluorescence intensity decreases gradually with the increasing amount of nitrobenzene substances; when the amount of nitrobenzene substances added reaches 0.20μmol, the quenching degree reaches 61.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com