Predictive control method and predictive control device for piezoelectric ceramic actuator based on fuzzy TS (Takagi-Sugeno) model

A technology of predictive control and piezoelectric ceramics, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as large amount of calculation, influence of inverse model accuracy, difficulty in applying response speed to piezoelectric ceramic actuators, etc. , to achieve the effect of reducing the amount of calculation, reducing the burden of calculation, and real-time precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

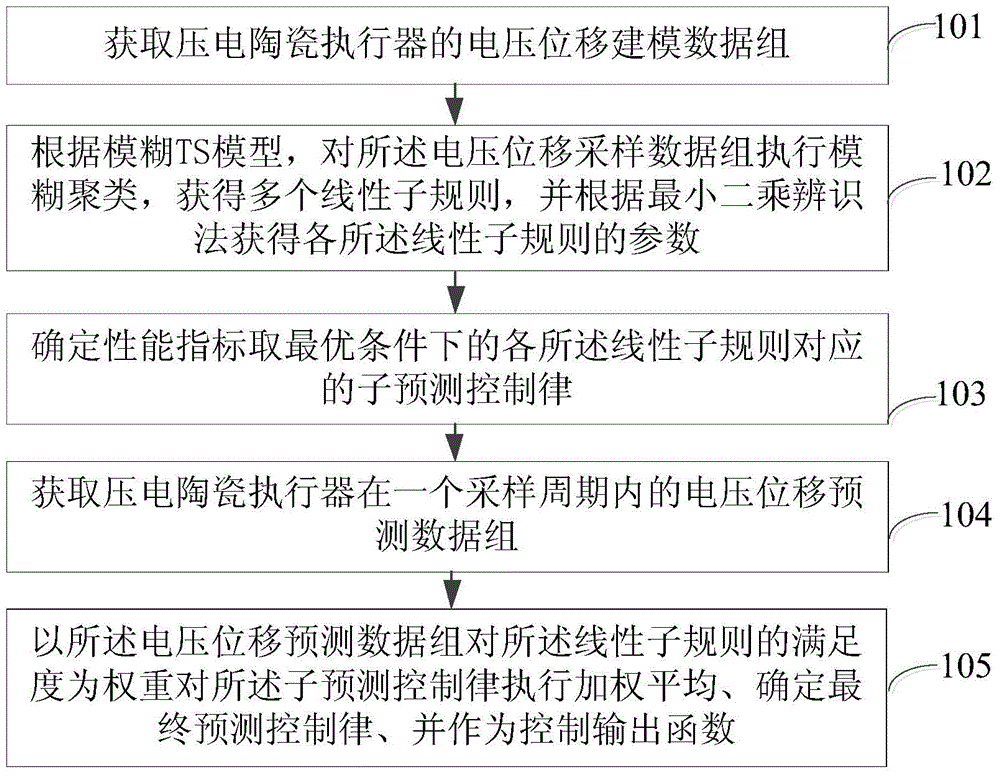

[0022] figure 1 It is a flow chart of Embodiment 1 of the predictive control method of the piezoelectric ceramic actuator based on the fuzzy TS model of the present invention, such as figure 1 Shown, the present invention is based on the predictive control method of the piezoelectric ceramic actuator of fuzzy TS model, comprises:

[0023] S101. Obtain the voltage displacement modeling data set of the piezoelectric ceramic actuator, preferably, including:

[0024] Obtain the voltage and displacement of the piezoelectric ceramic actuator, and express the voltage displacement data group in the form of the preceding vector:

[0025] X=[y(t-1),y(t-2),...,y(t-n y ),u(t),u(t-1),…,u(t-n u )]∈R p (1)

[0026] where n y is the maximum delay corresponding to the output y, n u is the maximum delay corresponding to the input quantity u, and the acquisition of the voltage and displacement of the piezoelectric ceramic actuator includes:

[0027] Converting the voltage excitation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com