Technological parameter alarming method during starting of chemical engineering device

A process parameter and chemical technology, which is applied in the alarm field of process parameters when chemical equipment is started, can solve problems such as misoperation and low safety factor, achieve good technical effects, and prevent errors or untimely effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

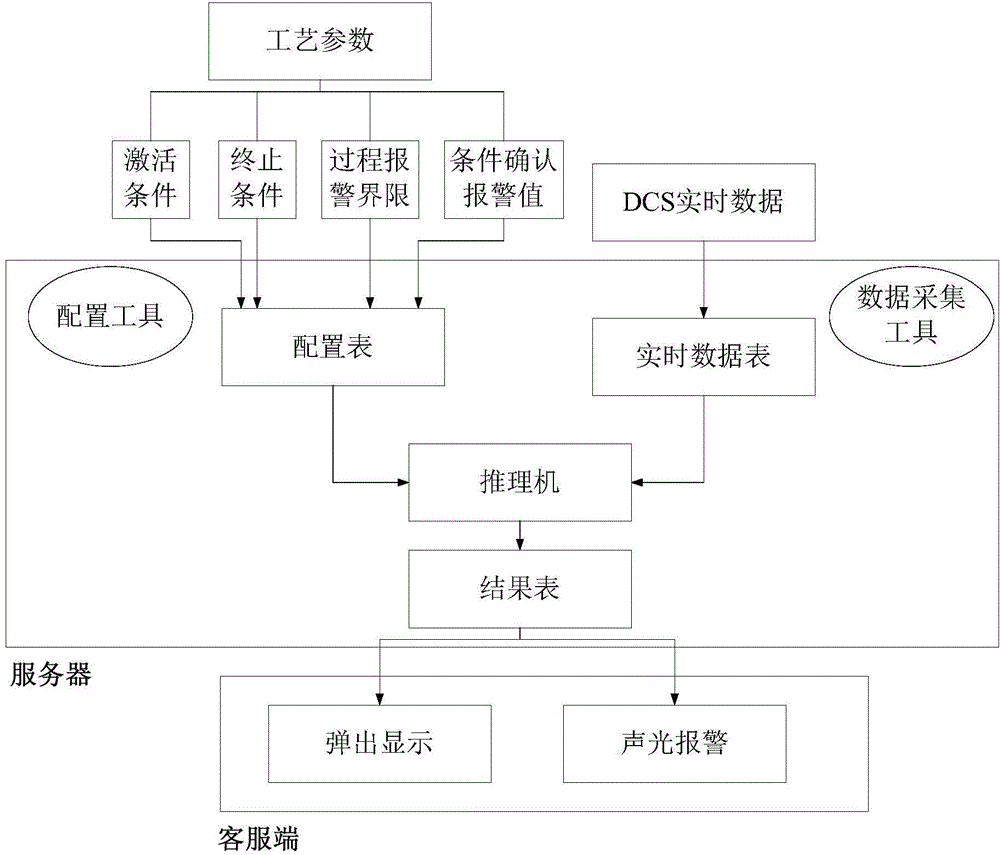

[0018] The invention relates to a method for alarming process parameters when a chemical plant is started, such as figure 1 As shown, it includes the following steps: (1) input the activation condition, termination condition, process alarm limit and condition confirmation alarm value of the process parameters into the configuration table in the server through the configuration tool; (2) input the DCS real-time data through the data acquisition tool The real-time data table of the server; (3) compare the real-time data with the activation condition, termination condition, process alarm limit and condition confirmation alarm value in the inference engine, and input meaningful comparison results into the result table; (4) The customer service end reads the data from the result table of the server, and according to the comparison result, an alarm is issued. When an alarm is issued, the consequences of exceeding the limit and handling suggestions are automatically popped up. The saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com