Calculation Method of Safe Thickness of Bearing Layer of Pile Foundation in Karst Area

A technology of safety thickness and calculation method, applied in calculation, special data processing application, instrument, etc., can solve problems such as not considering the influence of self-weight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0054] 1. Theoretical basis:

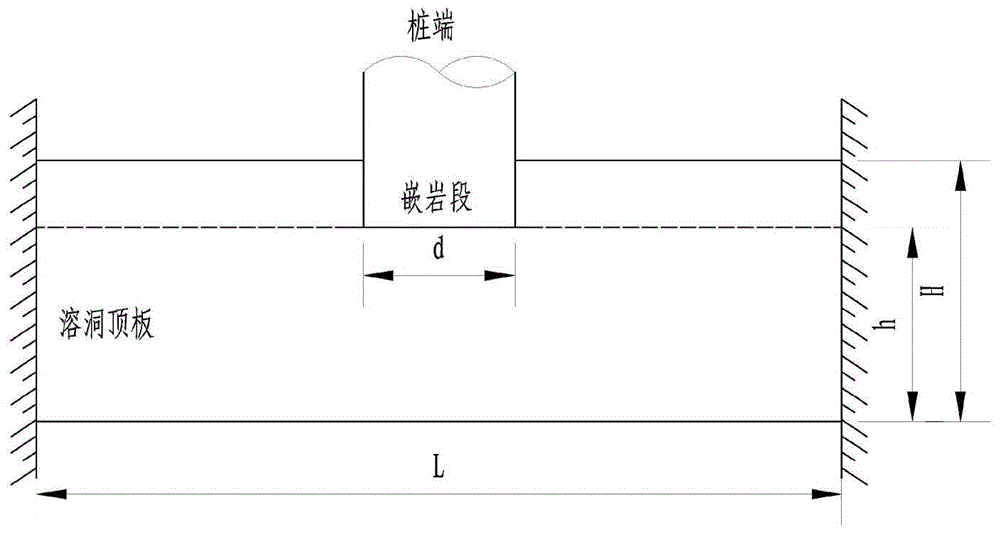

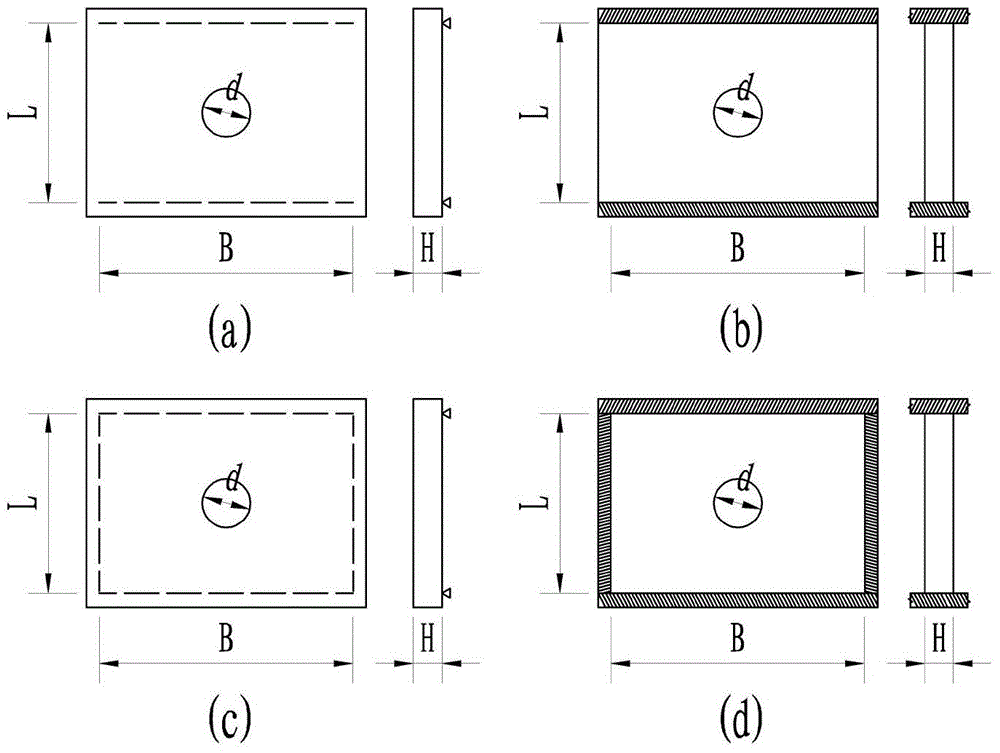

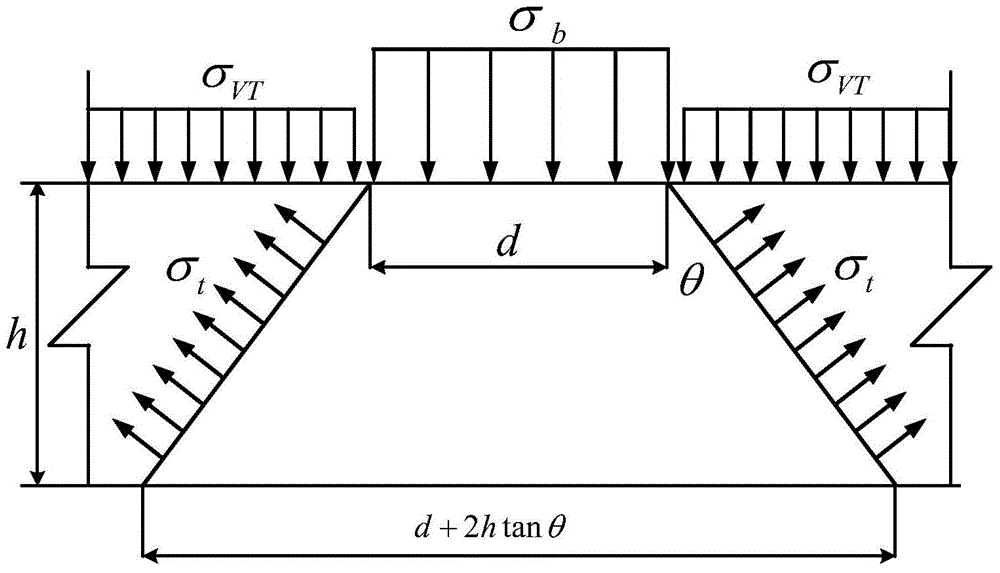

[0055] Assumption: In order to facilitate the analysis of the mechanism of action between the pile foundation and the karst roof, the two can be considered as a system. Considering that the failure of the karst roof is a typical brittle failure, which is safer, the model can be simplified to a rectangular plate subject to a mid-span concentrated load model (see figure 1), the roof strata generally may have three modes of punching failure, shear failure and bending-tension failure. And make the following basic assumptions:

[0056] (1) The rock mass around the cave is a continuous linear elastic body and the time effect is not considered, and the cave is stable in the natural state; (2) The rock mass around the cave is a uniform isotropic material; (3) The analysis does not include the The beneficial effects of fillings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com