Analysis and rheoforming numerical simulation method for alloy semi-solid rheoforming

A technology of semi-solid rheology and analysis method, applied in the direction of CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve the problems of complex and unestablished rheological behavior of semi-solid metal paste, and achieve parameters Less, improve efficiency, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

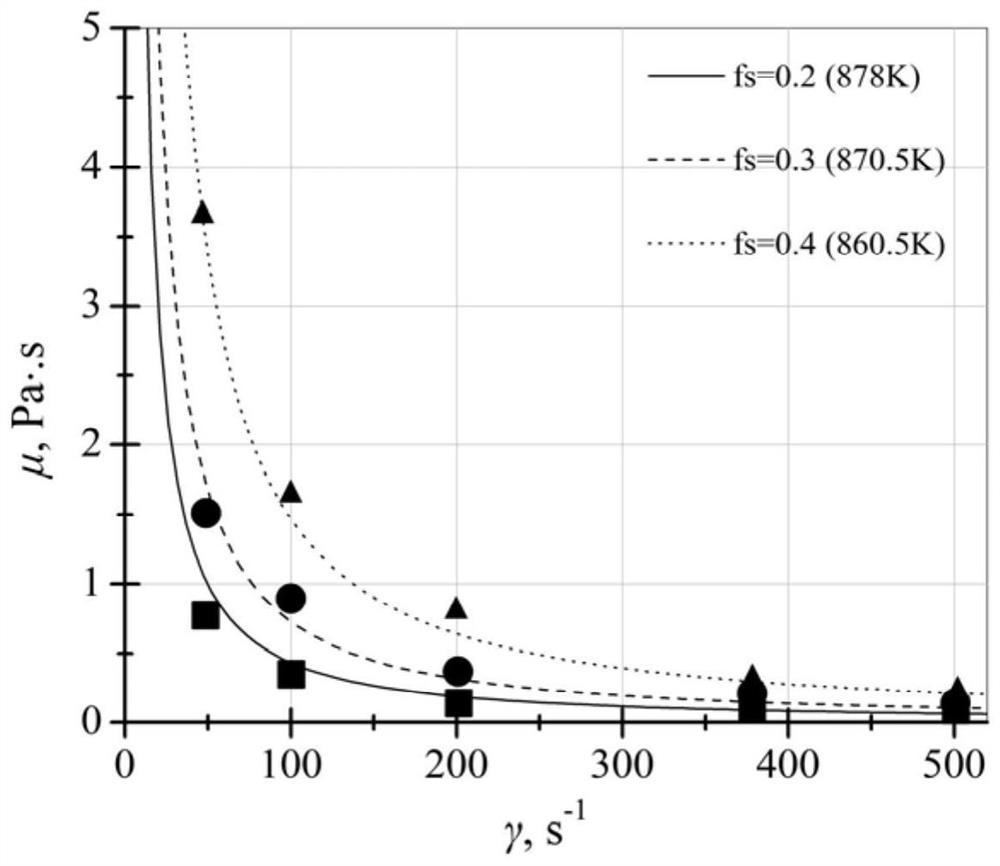

[0052] Viscometer is used to obtain the viscosity data of A356 aluminum alloy at different temperatures and different shear rates, as shown in Table 1, the data in Table 1 is fitted using the viscosity model of the present invention to obtain A356 aluminum alloy semi-solid slurry The relationship between the apparent viscosity of the material and the temperature and shear rate is shown in formula 1.

[0053]

[0054] A356 aluminum alloy melt viscosity changes with melt temperature and shear rate as follows figure 2shown. Comparing the fitted curve with the experimental values, it can be found that the data corresponding to the fitted viscosity model is in good agreement with the experimental values.

[0055] Table 1

[0056]

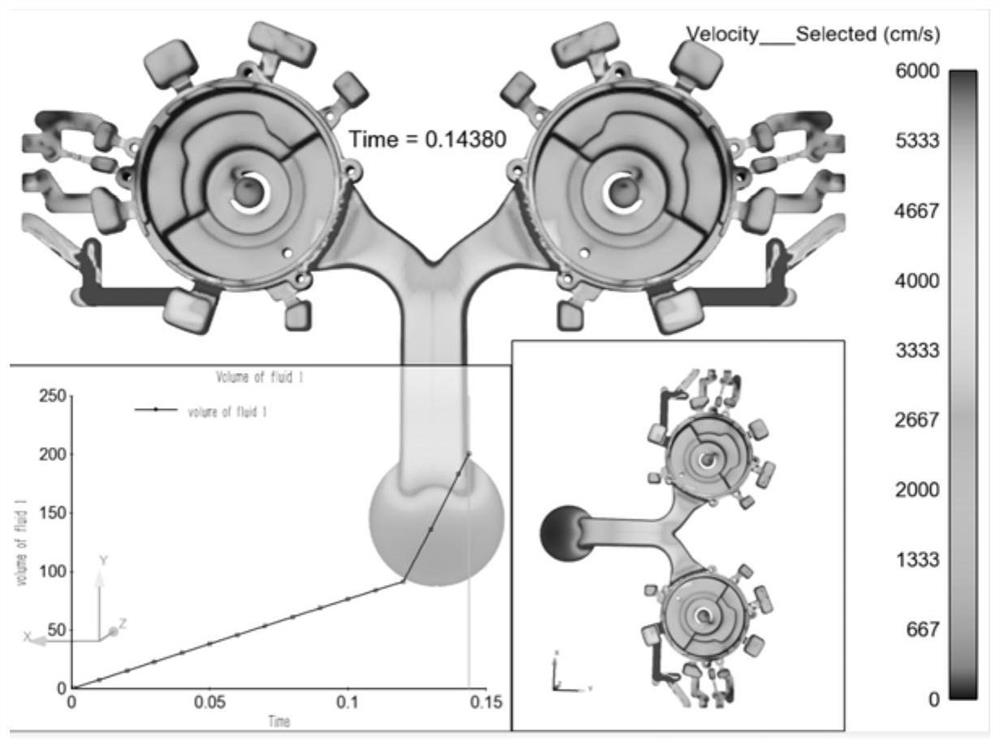

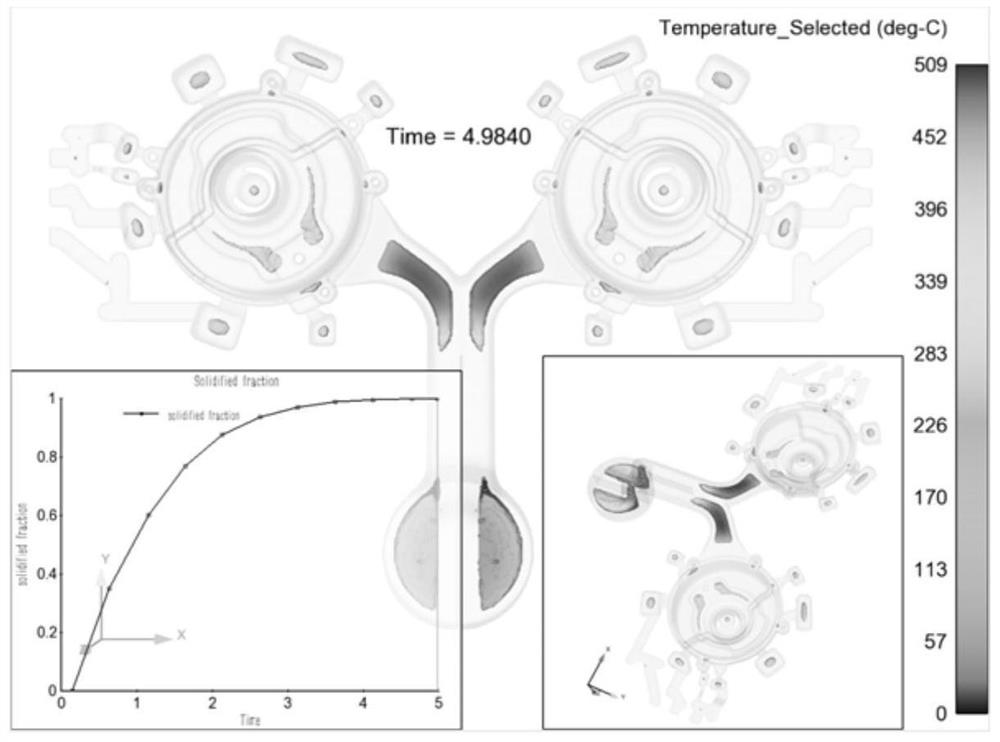

[0057] The semi-solid viscosity model of A356 aluminum alloy in Equation 1 is coupled with the basic fluid mechanics and flow equations of the simulation software, and the mathematical viscosity model of rheological deformation process is establ...

Embodiment 2

[0059] Adopt viscometer to obtain the viscosity data of AZ91D magnesium alloy under different temperatures and different shear rates, as shown in table 2, utilize viscosity model described in the present invention to figure 2 The data in is fitted, and the relationship between the apparent viscosity of the AZ91D magnesium alloy semi-solid slurry and the temperature and shear rate is obtained, as shown in formula 2.

[0060]

[0061] AZ91D magnesium alloy melt viscosity changes with melt temperature and shear rate as follows Figure 6 shown. Comparing the fitted curve with the experimental values, it can be found that the data corresponding to the fitted viscosity model is in good agreement with the experimental values.

[0062] Table 2

[0063]

[0064] The semi-solid viscosity model of AZ91D magnesium alloy in formula 2 is coupled with the basic equations of fluid mechanics and flow, and the mathematical model of rheological die-casting forming process is established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com