Assembly and welding technology of connector

A technology for assembling welding and connectors, which is applied in the direction of connection, circuit/collector parts, electrical components, etc. It can solve the problems of easy entanglement of core wires, inconvenient welding, and unsightly appearance, and achieve good welding quality, easy welding, The effect of neat wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

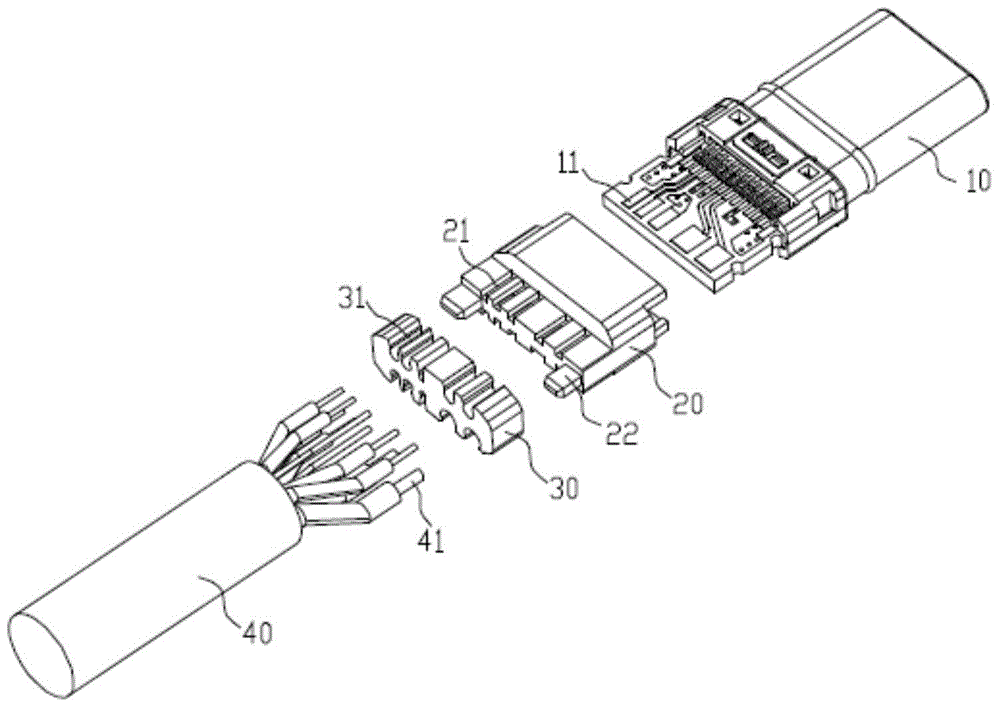

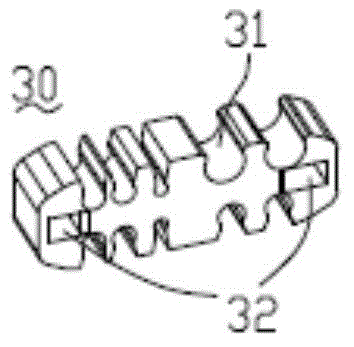

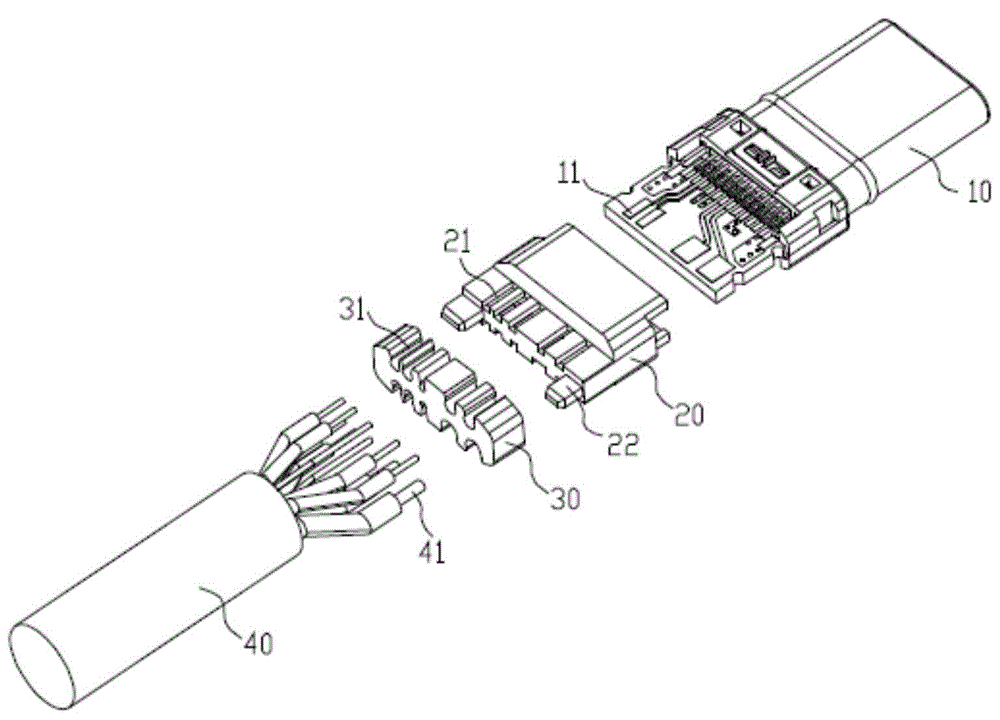

[0020] See Figure 1 to Figure 5 As shown, a connector assembly welding process, the connector includes a connector body 10, a pad clip 20 sleeved on the connector body 10 is provided with a printed circuit board end, and the pad clip 20 The fixed wire clamp 30, the pad clamp 20 and the wire clamp 30 are formed by injection molding. The printed circuit board of the connector body 10 is provided with a plurality of pads 11, and a tin layer is coated on the pads 11; the pad clip 20 is provided with an opening 21 and a convex portion 22, so that The openings 21 are arranged in one-to-one correspondence with the pads 11 on the connector body 10, and the convex portion 22 is fixedly arranged on one end surface of the pad cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com