An anode inlet nozzle for high power gas laser

A gas laser, air intake nozzle technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of poor gas turbulence, machine leakage rate, high gas consumption requirements, etc., to increase discharge stability The effect of reducing gas temperature and increasing gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

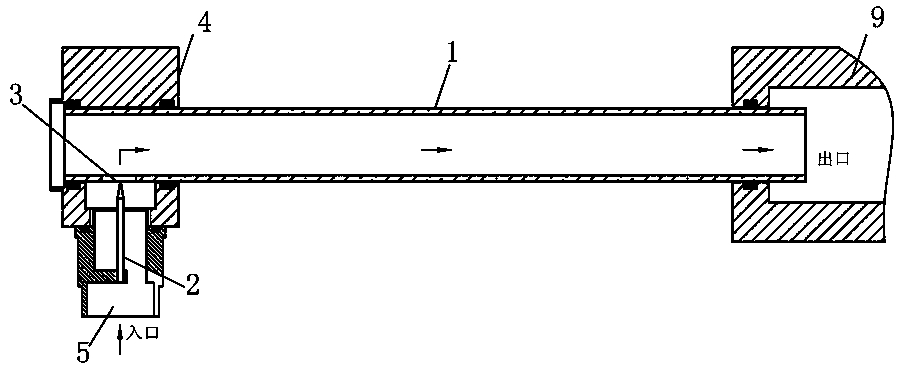

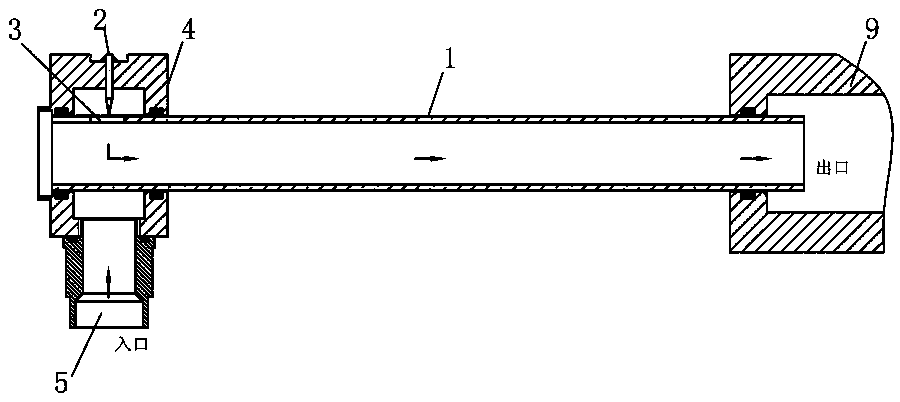

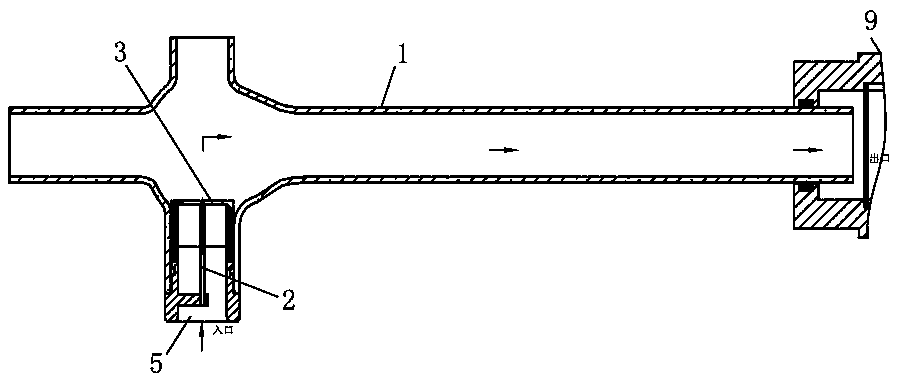

[0030] Example: such as Figure 4 to Figure 6 As shown, an anode intake nozzle for a high-power gas laser of the present invention includes a cross-shaped discharge tube 1, which also includes an anode needle seat 4, an anode needle 2 and a ceramic porous nozzle 7, and the anode needle seat 4 is fixed on ten At the gas inlet 5 of the glyph discharge tube 1, the ceramic porous nozzle 7 is fixed on the anode needle seat 4 and faces the cross-shaped cavity 8 of the cross-shaped discharge tube 1, and the anode needle 2 is fixed on the anode needle seat 4 and corresponds to the gas turbulence hole 3 provided on the ceramic porous nozzle 7.

[0031] The ceramic porous nozzle 7 is cylindrical, the outer diameter of the ceramic porous nozzle 7 is 18-24mm, the inner diameter of the ceramic porous nozzle 7 is 18-20mm, and the top thickness of the ceramic porous nozzle 7 is 0.8-2mm, so The gas turbulence holes 3 are arranged on the top of the ceramic porous nozzle 7 .

[0032] The gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com