Aerosol nucleation turbulent flow tube reactor capable of continuously adjusting reaction time

A reactor and flow tube technology, applied in the field of atmospheric chemical experiment research, can solve problems such as the loss of smoke chamber walls, and achieve the effects of continuous adjustment of reaction time, easy maintenance, and easy repeatability of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

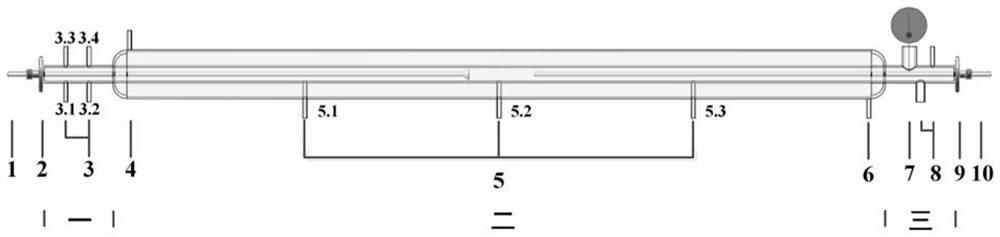

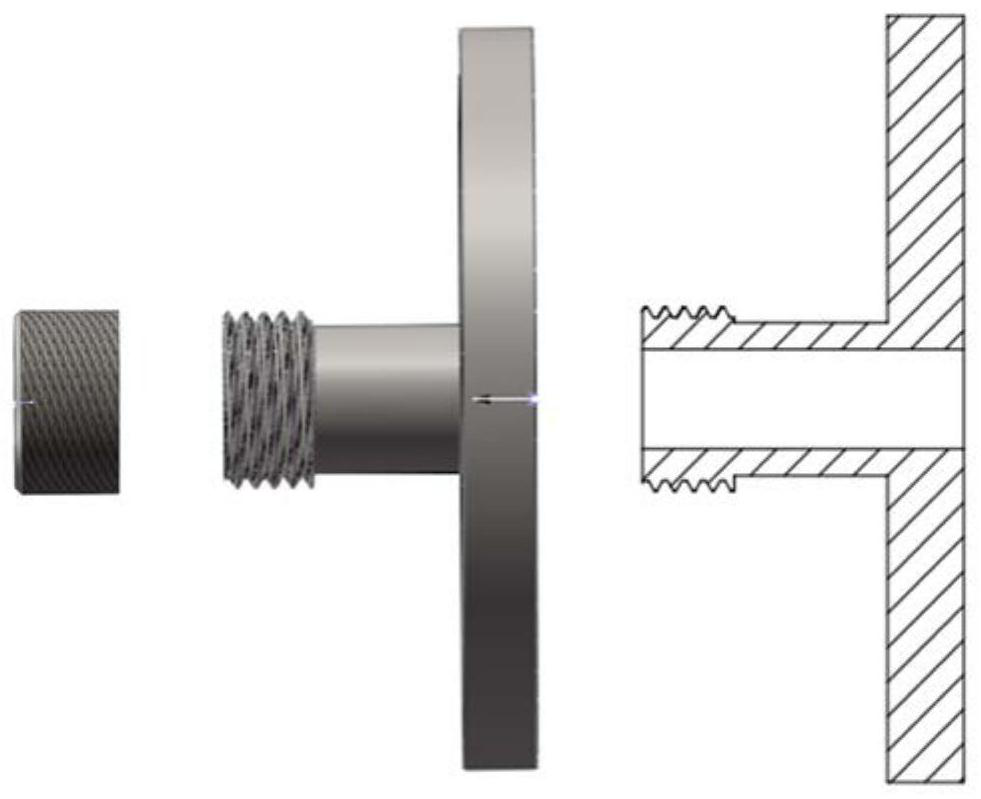

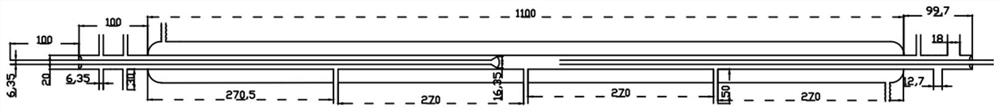

[0041] Aerosol nucleation turbulent flow tube reactor with continuously adjustable reaction time, the structure of which is figure 1 As shown, its dimensions are as image 3 As shown, where the dimensioning unit is mm. like figure 1 As shown, the aerosol nucleation turbulent flow tube reactor that can continuously adjust the reaction time is a shell structure made of quartz glass, mainly composed of an inner tube, a pullable sampling tube 1, a pullable sampling tube 10 and The outer tube is composed of components such as the inner tube. The inner tube is a tubular reaction chamber with a total length of 130cm, an inner diameter of 2cm, and an aspect ratio as high as 65. The sampling area (3) of the sampling position is composed of three integrated parts, which is an open integrated structure integrating gas mixing, aerosol nucleation, and aerosol sampling. Wherein, the left end of the inner tube is the sampling end, and the right end of the inner tube is the sampling end; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com