Width-adjustable cutting instrument for transapical aortic valve resectioning

An aortic and transapical technology, applied in the direction of surgical cutting instruments, endoscopic cutting instruments, dissection instruments, etc., can solve the problems of aortic valve not having the best fit, thrombus, inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

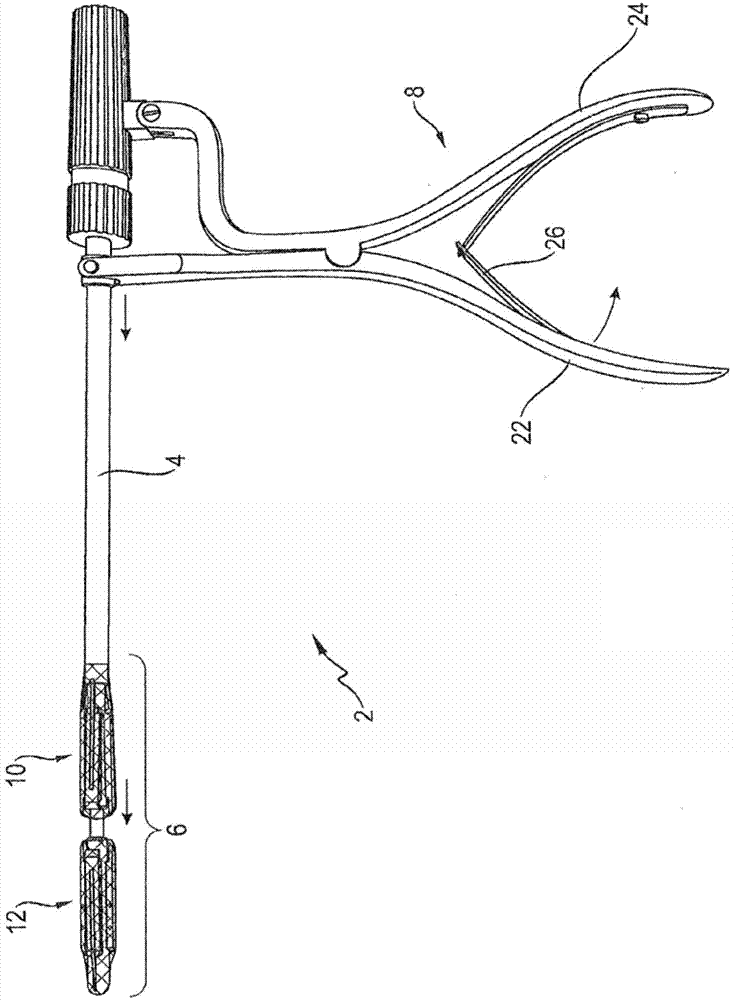

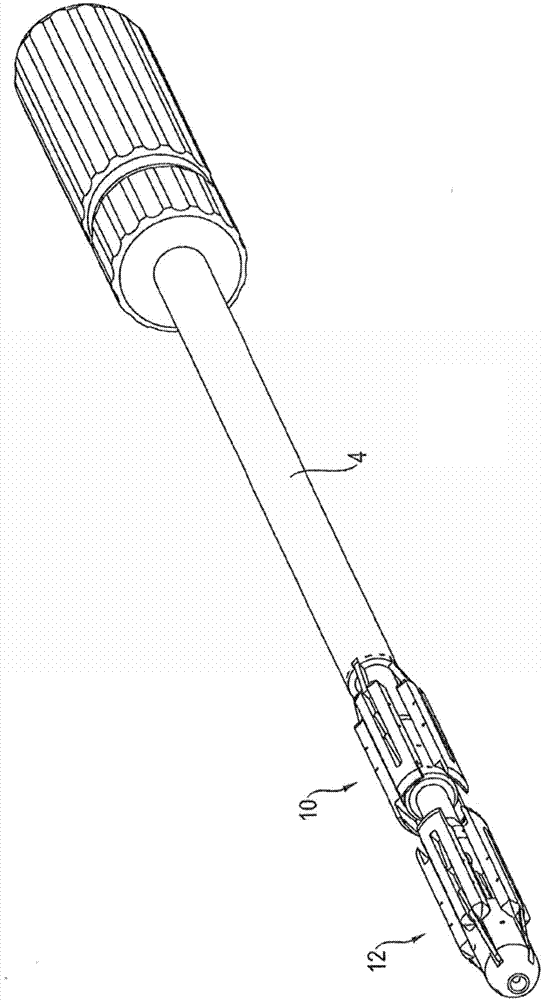

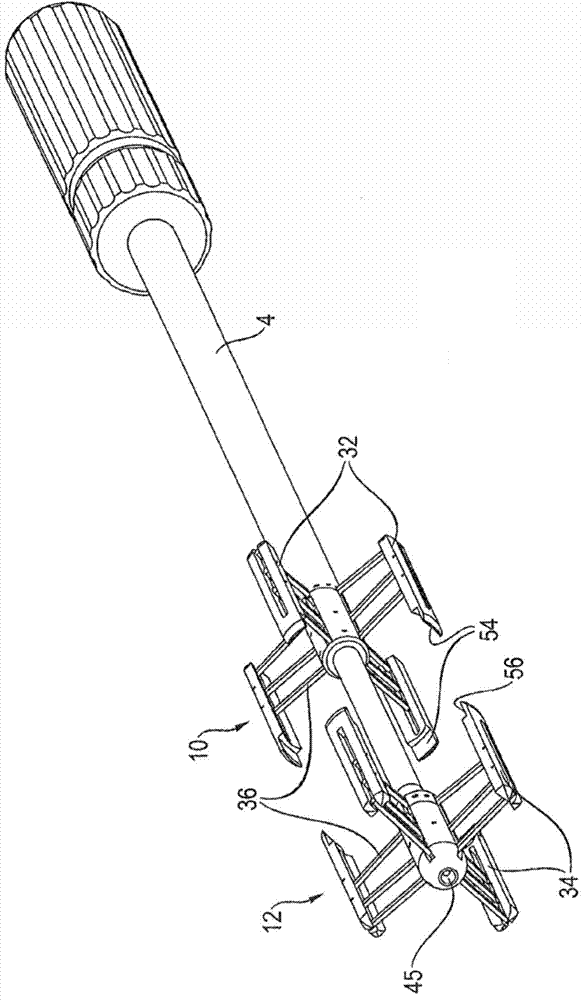

[0074] figure 1 A cutting instrument 2 is shown which is designed according to the invention and which has its distal end of the tool shaft 4 equipped with a cutting unit 6 which can be driven by means of a handpiece 8 arranged on the proximal end of the tool shaft 4 . The shaft 4 may be rigid or flexible; it may be possible to manipulate the shaft by means of a hand piece 8 if necessary. The cutting unit 6 is basically formed as a punch-die unit and consists of two cutting tools 10 and 12 which are arranged axially on the tool shaft 4 and which are movable towards and away from each other by means of a handpiece 8 . More precisely, the proximal cutting tool 10 in the illustrated example acts as a movable punch unit and the distal cutting tool 12 acts as a static die unit. Of course, in alternative designs, the distal cutting tool 12 can be moved towards the proximal cutting tool 10, or both cutting tools can be moved relative to each other.

[0075] The cutting tools 10, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com