Gating system capable of solving inner runner inflow unevenness

A gating system and sprue technology, which is applied in casting molding equipment, molds, cores, etc., can solve the problem of uneven inflow of sprue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

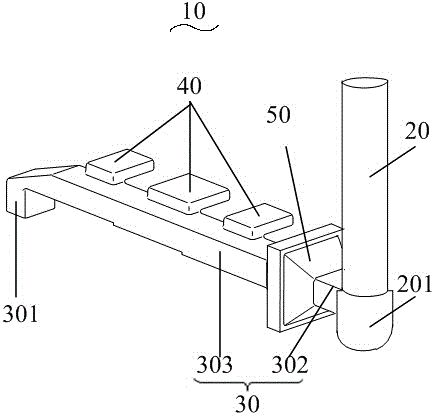

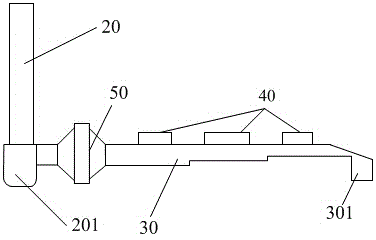

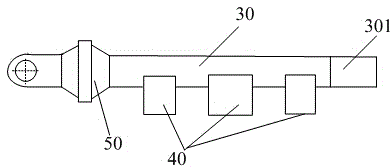

[0013] See Figure 1 to Figure 6 , the gating system 10 for solving the uneven inflow of the ingate includes a sprue 20 , a runner 30 and an ingate 40 , the upper end of the sprue 20 is used to connect the sprue basin, and the lower end is connected to the runner 30 , The bottom end of the sprue 20 is provided with a buffer dimple 201 for buffering molten iron. The cross-sectional area of the buffer dimple 201 is larger than that of the sprue 20, and the cross-section of the buffer dimple 201 and the cross-section of the sprue 20 are concentric circles. , the upper end surface of the joint between the runner 30 and the sprue 20 is flush with the top surface of the buffer dimple 201, the buffer dimple 201 can buffer the impact of the molten iron, and shorten the iron at the corner of the sprue 20 and the runner 30. liquid turbulence zone, thereby guiding the molten iron to flow into the runner 30 smoothly and slowly.

[0014] See Figure 1 to Figure 6 , the runner 30 is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com