New energy commercial vehicle energy efficient recovery system

A recovery system and commercial vehicle technology, applied in the field of new energy commercial vehicle braking energy recovery system, can solve the problems of brake wear, small brake pedal working angle, low charging efficiency, etc., and achieve the effect of improving efficiency and increasing power generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

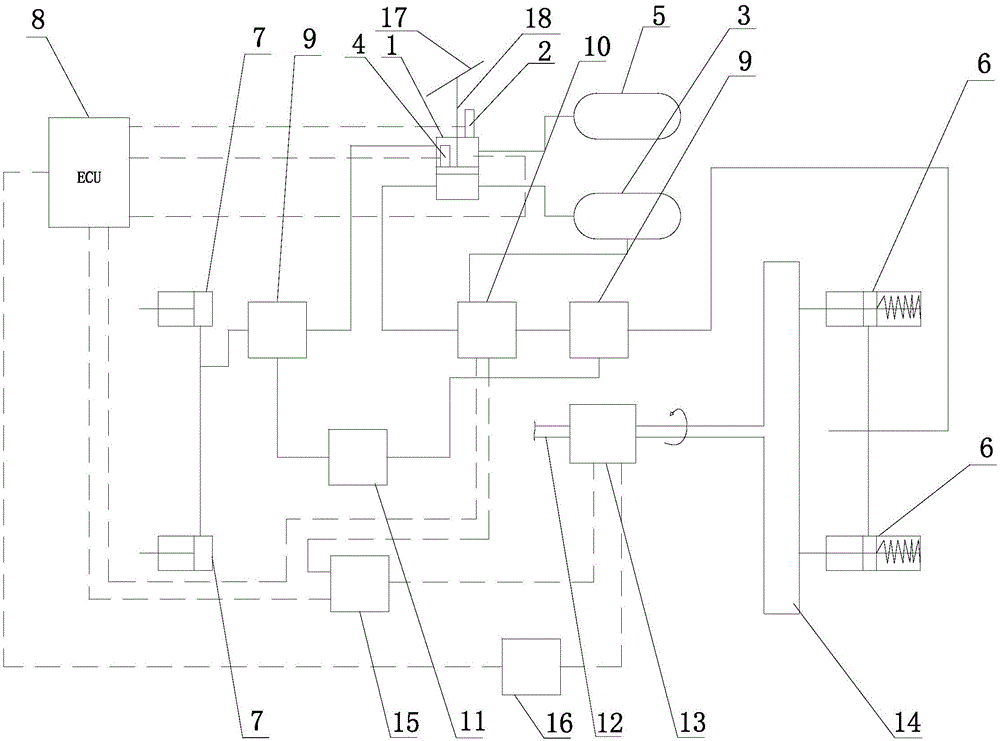

[0017] figure 1 Among them, a high-efficiency energy recovery system for new energy commercial vehicles, including ECU electronic control unit 8, electromagnetic foot valve 1, proportional relay valve 10, front and rear ABS solenoid valves 9, ABS controller 11, generator 13, front axle and rear axle Axle 14, the front axle is provided with a diaphragm compartment 7, the rear axle 14 is connected with a drive shaft 12, the drive shaft 12 is provided with the above-mentioned generator 13, the generator 13 is connected with the storage battery 15, and the generator 13 is controlled by the generator controller 16 is connected with the ECU electronic control unit 8, the rear axle 14 is provided with a spring brake chamber 6, the electromagnetic foot valve 1 is provided with a pedal 17 and a push rod 18 under the pedal 17, the upper air storage tank 5 and the lower air storage tank 3 are respectively It is connected with the air inlet of the upper chamber and the air inlet of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com