Biological sludge zero-discharge sewage treatment plant and method

A biological sludge, zero-discharge technology, applied in biological sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of increasing the accumulation of inorganic substances, reducing the ratio of VSS/MLSS, affecting normal operation, etc. problem, to achieve high activity, inhibit sludge bulking, and promote energy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

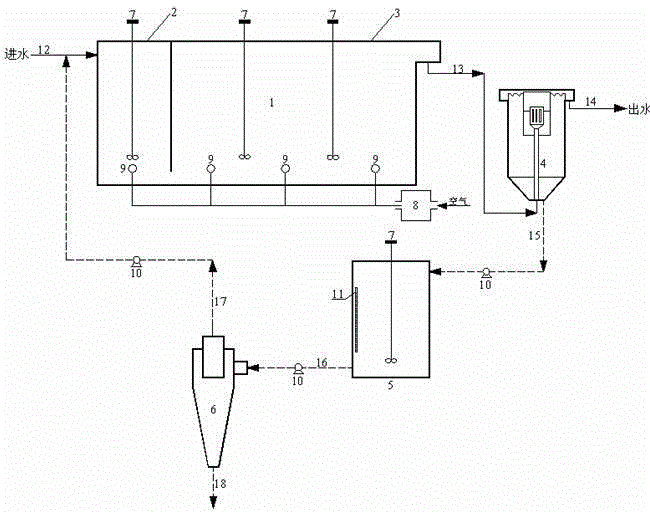

[0021] see figure 1 , the device consists of an aeration tank 1, a secondary sedimentation tank 4, and an anaerobic decoupling tank 5 to form the main process of OSA sludge reduction. Biological sludge and inorganic sand separator 6 is embedded in the return sludge pipeline. The raw sewage enters the aeration tank 1 through the water inlet pipe 12 and the highly active organic sludge from the overflow sludge port of the separator 6 through the return sludge pipe 17. The bottom of the secondary sedimentation tank 4 and the inlet of the anaerobic decoupling tank 5 are connected by a return sludge pipe 15, and the bottom of the anaerobic decoupling tank 5 and the inlet of the separator 6 It is connected by the return sludge pipe 16, the secondary settling tank 4 is discharged from the top sewage pipe 14, and the separator 6 discharges the remaining sludge (inorganic sludge) from the bottom outlet through the sludge pipe 18.

[0022] The return flow of sludge in the system is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com