Offshore thick oil heat injection and oil extraction pipe column and method

An oil production pipe and heat injection technology, applied in drilling pipes, casings, production fluids, etc., can solve the problems of production shutdown, loss of sand-retaining function of screen pipes, and high investment costs, so as to extend production life, reduce the impact of temperature changes, reduce the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

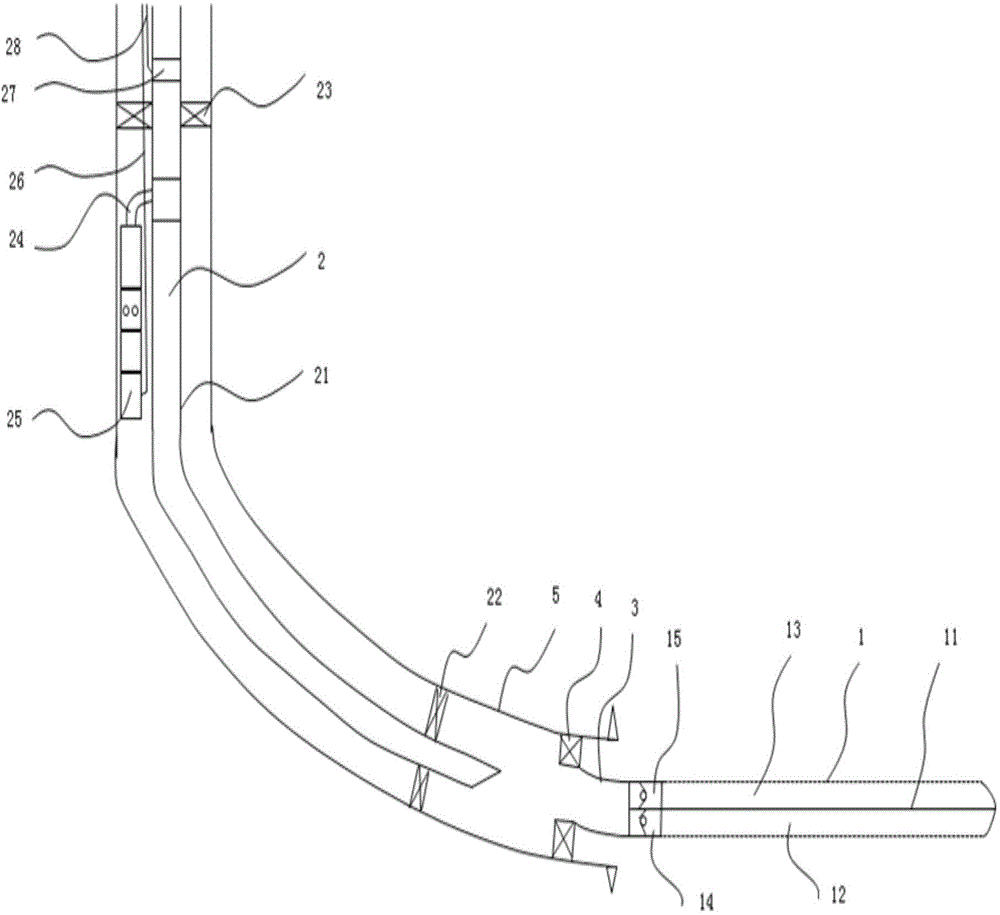

[0012] The offshore heavy oil heat injection and production string of the present invention at least includes a sand control screen 1 and a central string 2; the sand control screen 1 is divided into a heat injection chamber 12 and an oil recovery production chamber by an internal partition 11 of the sand control screen 13. The top of the heating chamber is equipped with a check valve 14 that can flow into the sand control screen, and the top of the oil production chamber is equipped with a check valve 15 that can flow out of the sand control screen. The sand control screen passes through the blind pipe 3 and the sand control pack The device 4 is connected with the oil layer casing 5; the central string 2 is located in the lower part of the oil layer casing 5, and can be lifted and lowered repeatedly; the oil pipe 21 is fixed in the center of the oil layer casing 5 by the bottom packer 22 and the cable packer 23; 21 is connected to the electric submersible pump unit 25 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com