Damping spring vibration isolator device with expansion sleeves and mounting and adjusting construction method thereof

A technology of damping springs and expansion sleeves, which is applied in the direction of springs/shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as unsatisfactory accuracy, cumbersome on-site leveling, and long movable strokes of dampers, and achieve installation It is easy to adjust the construction method, improve the construction production efficiency, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

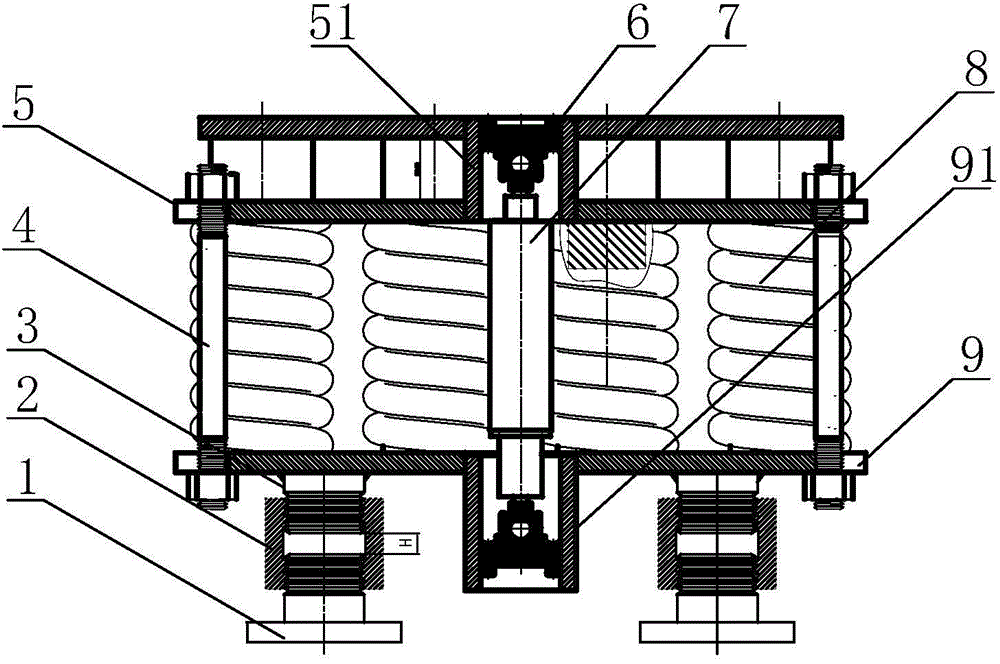

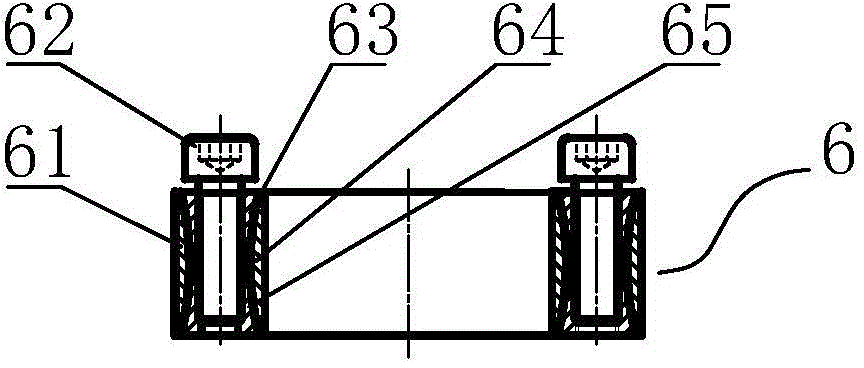

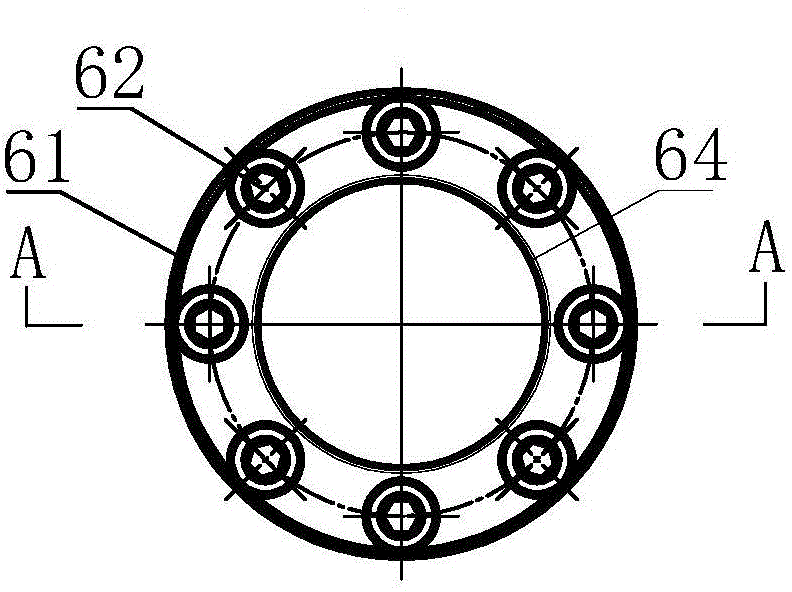

[0042] A damping spring vibration isolator device with expansion sleeves, including an upper pressure bearing plate part 5, a spring 8, a lower pressure bearing plate part 9 and a damper assembly 7, and the spring is installed between the upper and lower pressure bearing plate parts , the damper assembly is installed between the upper and lower pressure plate parts in the middle of the damping spring vibration isolator device, the axial direction of the damper assembly is parallel to the spring length direction, and the upper and lower pressure plate parts are passed through the tight The solid assembly 4 is fixed;

[0043] The upper and lower pressure bearing plate parts are connected with an upper sleeve and a lower sleeve for installing the damper assembly, and the upper end of the damper assembly is connected to the sleeve sleeve 51 on the upper pressure bearing plate component through the expansion sleeve 6 , the lower end of the damper assembly is connected to the sleeve...

Embodiment 2

[0049] An installation and adjustment method of a damping spring vibration isolator device with an expansion sleeve, comprising the following steps:

[0050] The first step is to assemble the damping spring isolator device with expansion sleeve:

[0051] 1) Assemble the upper and lower bearing plate parts and the spring 8 into one body, and lock them with the fastening component 4 after applying pre-pressure;

[0052] 2) Put the damper assembly 7 from the upper sleeve 51 of the upper bearing plate part to a given position in the lower sleeve 91 of the lower bearing plate part, and the sleeve and the damper under the lower bearing plate part The expansion sleeve 6 is placed between the spherical hinge parts of the assembly, and the lower end of the damper assembly and the lower bearing plate part are locked and integrated into one through the locking bolts 62 on the expansion sleeve;

[0053] 3) Put the expansion sleeve 6 between the upper cylinder sleeve of the upper pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com