Manufacturing method of bimetallic composite wear-resistant liner

A technology of wear-resistant liner and manufacturing method, which is applied in the field of machinery and mechanical parts of coal-fired thermal power stations, can solve the problems of plastic deformation, poor toughness, poor crack resistance tendency, and low wear resistance, and achieve appropriate hardness and impact toughness , Refinement of material organization structure, stable and reliable effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

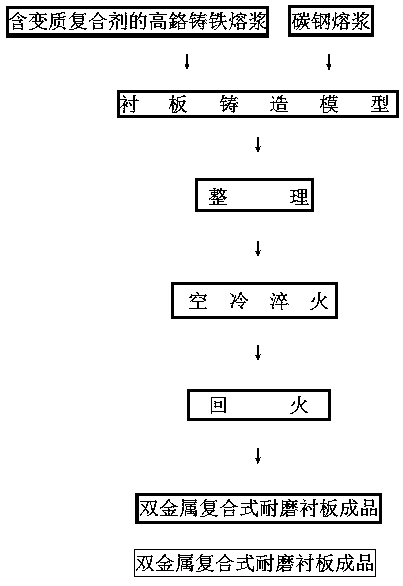

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

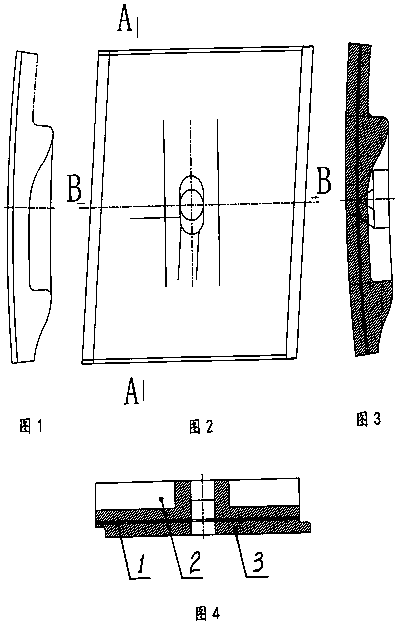

[0049] A method for manufacturing a bimetallic composite wear-resistant liner. The bimetallic composite wear-resistant lining is composed of an intermediate steel plate 1, a high-chromium iron casting 2, and a carbon steel casting 3. One side of the intermediate steel plate 1 is made of The other side of the high-chromium iron casting 2 formed after the high-chromium cast iron magma of the composite agent is solidified, the other side of the middle steel plate 1 and the carbon steel casting 3 formed after the solidification of the carbon steel magma are all connected by casting;

[0050] Both the middle steel plate 1 and the carbon steel casting 3 are plate-shaped structures provided with bolt holes, and the high-chromium iron casting 2 is a plate-shaped structure provided with bolt counterbores and sawtooth-shaped protruding te...

specific Embodiment approach 2

[0064] Carry out according to specific embodiment one. As attached to the manual figure 1 , 2 , 3, and 4 show:

[0065] A bimetal composite wear-resistant liner, which is composed of an intermediate steel plate 1, a high-chromium iron casting 2, and a carbon steel casting 3;

[0066] The bimetallic composite wear-resistant liner, one side of the middle steel plate 1 and the high chromium iron casting 2 formed after the solidification of high chromium cast iron lava containing metamorphic compounding agent, the other side of the middle steel plate 1 and the other side of the middle steel plate 1 and the carbon steel melting The carbon steel castings 3 formed after the slurry is solidified are all connected by casting.

[0067] For the bimetallic composite wear-resistant liner, the middle steel plate 1 and the carbon steel casting 3 are plate-shaped structures provided with bolt holes, and the high-chromium iron casting 2 is provided with bolt counterbores and sawtooth A pla...

specific Embodiment approach 3

[0069] Carry out according to specific embodiment one. As attached to the manual Figure 5 Shown:

[0070] A method for manufacturing a bimetal composite wear-resistant liner, the manufacturing steps are as follows:

[0071] ①. Fabrication of lining plate casting model: On one side of the middle steel plate 1, the high-chromium iron casting 2 model made of polystyrene foam board is bonded with lost foam cold glue, and on the other side of the middle steel plate 1, it is glued with lost foam cold glue Connect the carbon steel casting 3 model made of polystyrene foam board, the high chromium iron casting 2 model, the middle steel plate 1, and the carbon steel casting 3 model together constitute the lining plate model; brush the surface of the lining plate model more than 3 times thick After the lost foam coating is 1.5-2.5 mm, it is dried at 40-50°C; the dried lining board model is placed in a sand box, filled with sand and vibrated, covered with a plastic film, and then a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com