Full-section advanced curtain grouting construction method for water-rich broken geological zone tunnel

A technology of breaking geology and advanced curtain, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of high pumping and drainage pressure, high risk of flooding, damage to the surface ecological environment, etc., to save construction costs, safe secondary lining effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

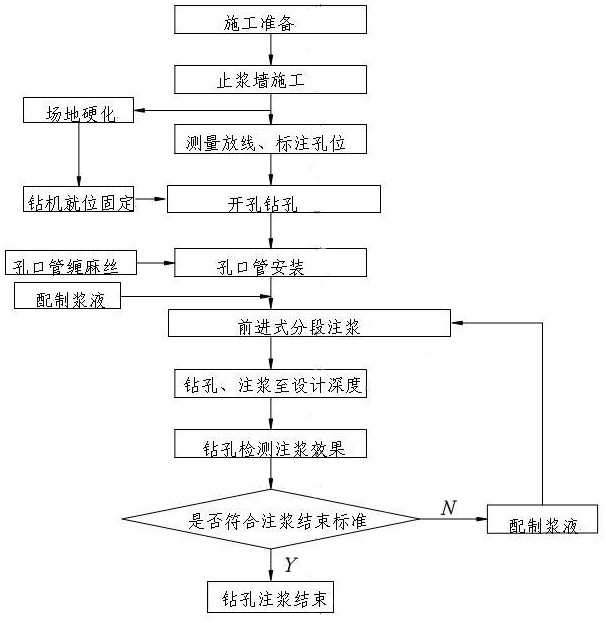

Method used

Image

Examples

Embodiment

[0062] Example: The designed surrounding rock of the tunnel is medium to slightly weathered granite, the geological conditions are extremely complex, and cracks are developed. The tunnel site passes through 16 fault structures and multiple low-resistance anomaly zones. The 1262m section from the tunnel entrance to K94+480 is a forward slope with a slope of -0.4%. With K94+480 as the boundary along the excavation direction, it is a reverse slope, that is, the downhill section with a slope of 2%. The construction length of the reverse slope is 2.0Km. The water gushing face of the line is located in the reverse slope section of the tunnel, which causes the water seepage and gushing water in the tunnel to collect along the slope to the face of the tunnel under the action of gravity. Therefore, it is necessary to pump and drain the accumulated water in time to prevent the water accumulation on the face of the construction face from being too deep , affecting the stability of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com