Built-in blade motor type energy recovery absorber

An energy recovery, vane motor technology, applied in liquid shock absorbers, machines/engines, elastic suspensions, etc., can solve the problems of function failure and low energy utilization, and achieve the effect of high-efficiency electrical energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

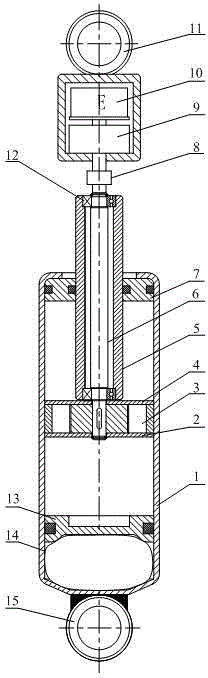

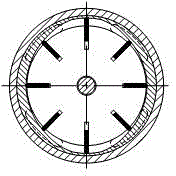

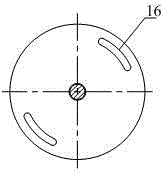

[0019] As attached to the manual figure 1 As shown, a built-in vane motor type energy recovery shock absorber mainly includes a vibration damping cylinder, a piston, a transmission mechanism, a motion conversion mechanism and a generator. The damping cylinder includes a cylinder body (1) and a hollow piston rod (5); the piston is composed of a built-in double-acting vane motor (3), an upper sealing plate (2), a lower sealing plate (4), and an upper sealing plate ( 4) Two upper sealing plate waist-shaped windows (16) are processed in the working area corresponding to the vane motor, and the lower sealing plate (2) is processed with two lower sealing plate waist-shaped windows (17) in the working area corresponding to the vane motor; The transmission mechanism consists of an output shaft (6), a bearing (12) and a coupling (8).

[0020] The piston is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com