Chiral sensor based on chitosan/cyclodextrin dinuclear copper and manufacturing method of chiral sensor

A cyclodextrin dual-nuclear copper and chitosan technology is applied in the field of electrochemical sensors and molecular recognition, which can solve the problems of long analysis time, high instrument cost, and difficulty in in-situ and online detection, and achieves high detection sensitivity and preparation. The method is simple and the effect of detecting the appropriate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

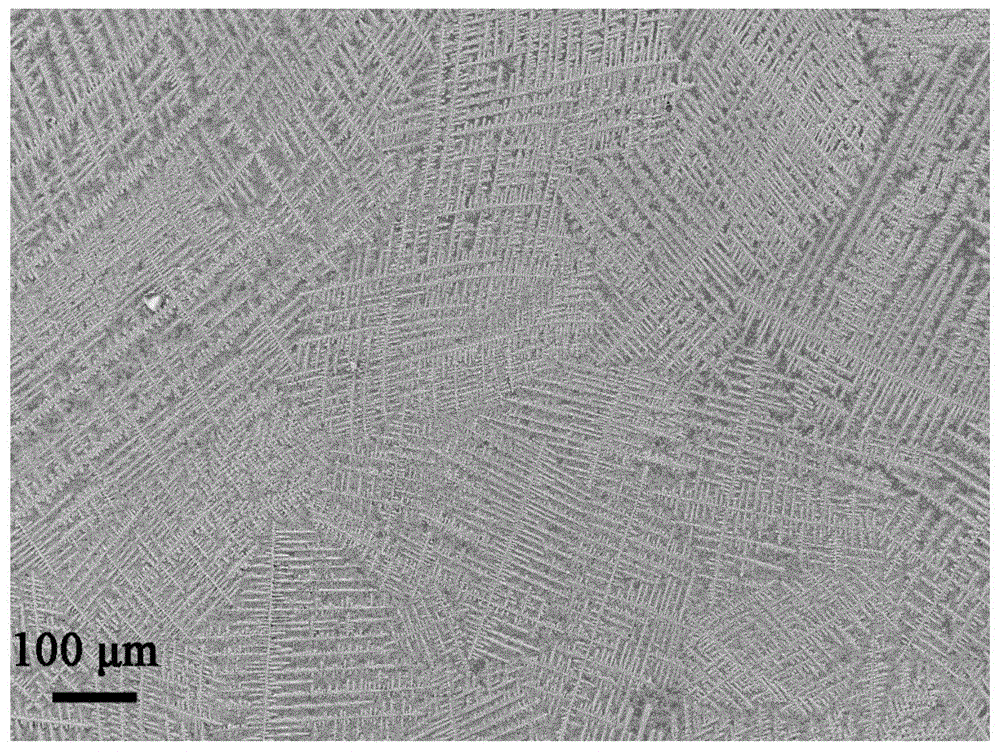

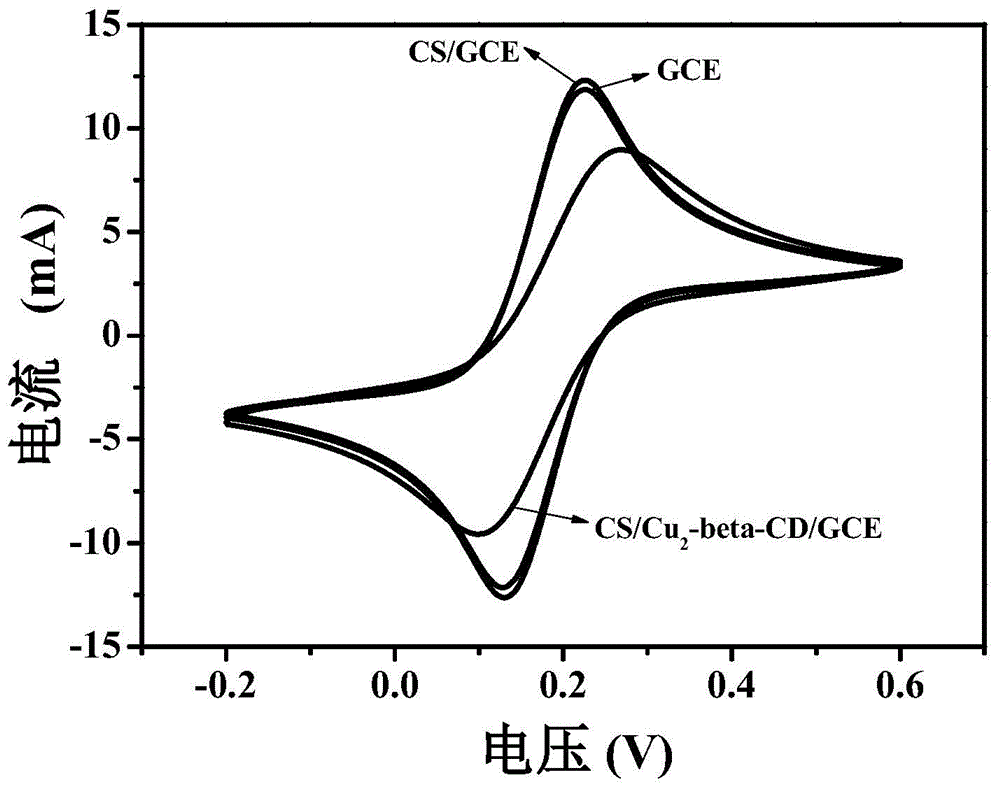

Image

Examples

Embodiment 1

[0031] (1) Configure 5mM Cu 2 -β-CD solution (the solvent is 0.1M PBS, pH=7.0-9.0).

[0032] (2) Prepare CS solution (solvent is 0.1-0.3M HCl, pH=1.0-2.0), and deposit on the surface of glassy carbon electrode by constant potential to obtain non-alkali-treated CS / GCE modified electrode; place the electrode in alcohol The ammonia solution was subjected to alkali treatment for 15 minutes, then rinsed with a small amount of ethanol, and placed in air to dry to obtain an alkali-treated CS / GCE modified electrode.

[0033] (3) Place the electrode prepared in step 2 on the Cu prepared in step 1 2 -18~28h in β-CD solution, self-assembled to obtain CS / Cu 2 - β-CD modified electrodes.

Embodiment 2

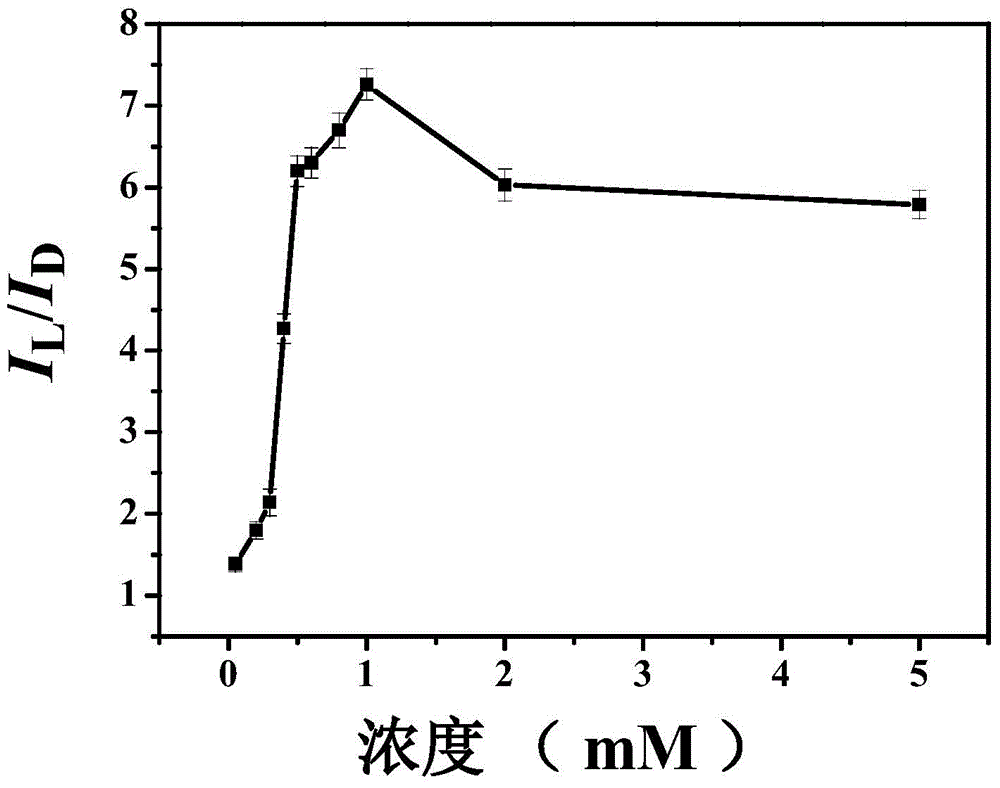

[0035] In order to investigate CS / Cu 2 - Differences in the recognition ability of β-CD modified electrodes to different concentrations of Trp enantiomers.

[0036] Therefore, 0.05 mM, 0.2 mM, 0.3 mM, 0.4 mM, 0.5 mM, 0.6 mM, 0.8 mM, 1 mM, 2 mM, 5 mM of the Trp enantiomers were used, respectively. See the result image 3 , it can be seen that when the concentration of Trp enantiomer is 1mM, the oxidation peak current ratio of L / D-tryptophan (L / D-Trp) reaches the maximum.

Embodiment 3

[0038] In order to examine the different deposition times of CS, the CS / Cu 2-Differences in the ability of β-CD modified electrodes to recognize Trp enantiomers. Therefore, adopt the deposition time of 150s, 300s, 350s, 375s, 400s, 450s respectively, carry out the recognition of Trp enantiomer, its result sees Figure 4 , when the deposition time is 375s, CS / Cu 2 -The β-CD modified electrode has the best recognition effect on the Trp enantiomer. When the deposition time is too short, the amount of chitosan deposited on the surface of the glassy carbon electrode is relatively small, so that the quality of the formed chitosan film reaches Less than the desired experimental effect. When the deposition time is too long, the amount of chitosan adsorbed on the surface of the electrode will be too much, so that the thickness of the formed chitosan film will be thickened, which is not conducive to Cu 2 -Self-assembly of β-CD, affecting Cu 2 -β-CD interacts with chitosan, thereby a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com