Low power hid lamp drive circuit

A driving circuit and low-power technology, applied in the field of low-power HID lamp driving circuit, can solve the problems of inconvenient use, unfavorable arc formation and maintenance of HID lamps, difficult lighting of HID lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

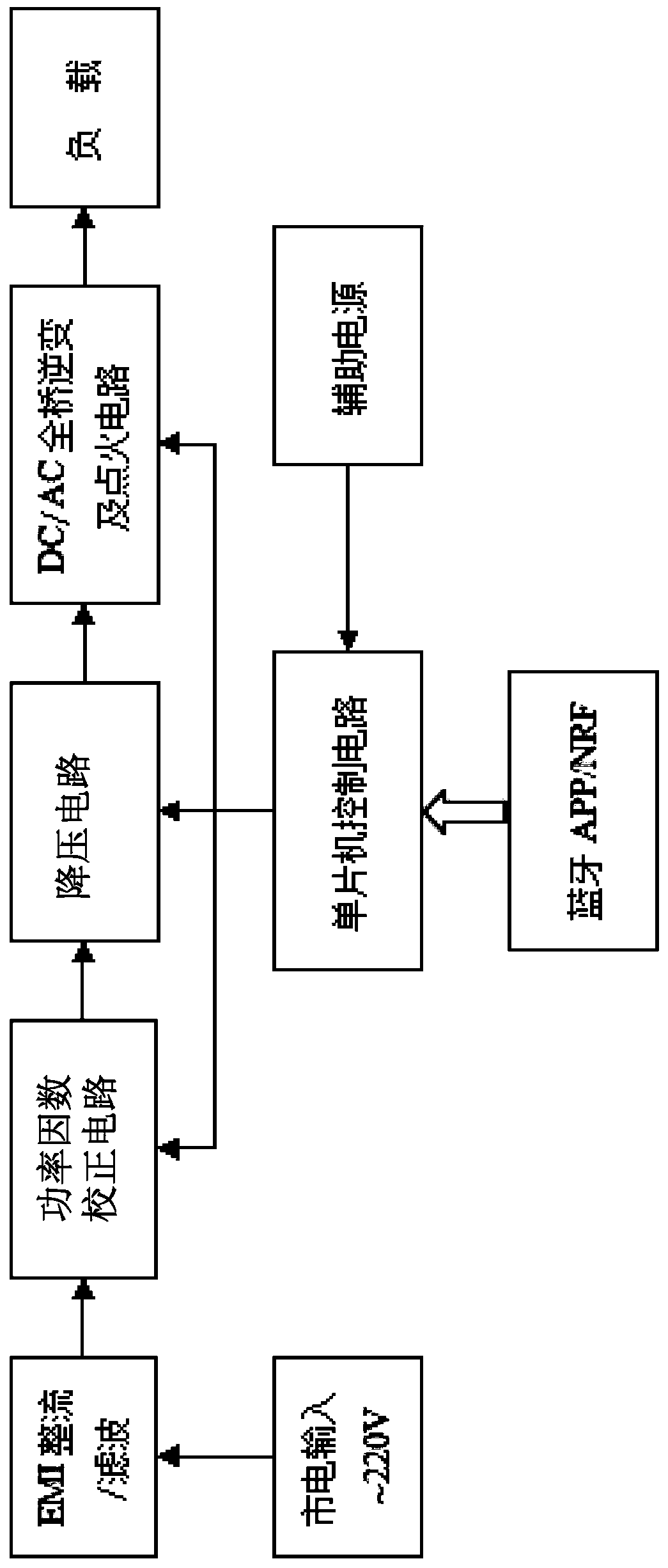

[0026] The low-power HID lamp drive circuit of the present invention, such as figure 1 As shown, it includes EMI rectification / filtering circuit, power factor correction circuit, step-down circuit, DC / AC full-bridge inverter and ignition circuit and single-chip microcomputer control circuit. The input end of the EMI rectification / filtering circuit is connected to the mains input power ~220V, and the output end of the EMI rectification / filtering circuit is connected to the power factor correction circuit, step-down circuit, DC / AC full-bridge inverter and ignition circuit in turn, and the DC / AC full-bridge The output end of the bridge inverter and the ignition circuit is connected to the load, and the output end of the single-chip microcomputer control circuit is respectively connected with the corresponding control ends of the power factor correction circuit, the step-down circuit and the full-bridge inverter and the ignition circuit.

[0027] Electromagnetic Interference (EMI)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com