Potato planting machine

A technology for planting machines and potatoes, which is applied in the field of agricultural machinery, can solve the problems of structural defects, low degree of automation, and low sowing accuracy of potato planting machines, and achieve the goal of enhancing ridging effects, reducing labor costs, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

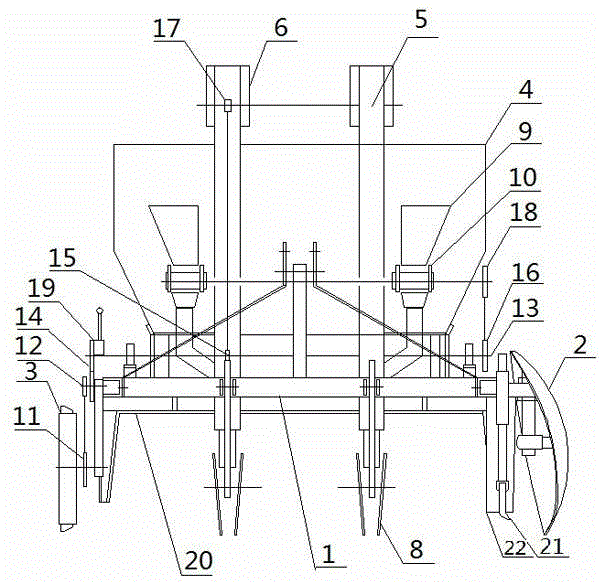

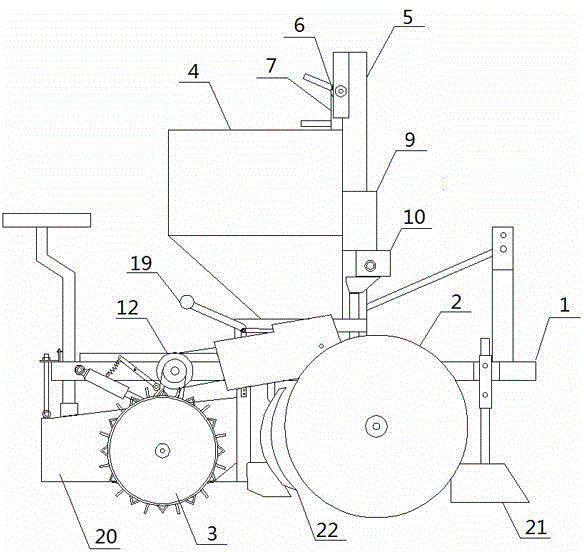

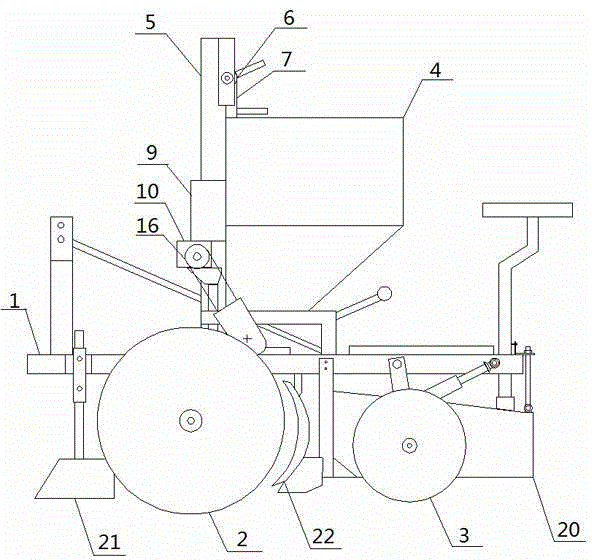

[0017] Such as Figure 1 to Figure 3 A potato planting machine shown includes a frame body 1, and the frame body 1 is provided with a ridging disc 2 and a ground wheel 3 in sequence from front to back, and an adjustable soil lifting shovel is arranged in front of the ridging disc 2 21. A soil retaining plate 22 is provided behind the ridging disc 2, ground teeth are provided on the wheel surface of the ground wheel 3, and a ridging soil board 20 with a trapezoidal cross section is provided at the rear of the frame body 1; The frame body 1 is provided with a seed storage box 4, and the side wall of the seed storage box 4 is vertically provided with a seed discharge pipe 5, and the seed discharge port of the seed discharge pipe 5 is located below the frame body 1; 5 is vertically provided with a lifting device, which includes a transmission sprocket 6 and a lifting chain 7 with a hopper, and the lifting chain 7 extends into the seed storage box 4; the bottom of the frame body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com