A head shrinking machine

A technology of necking and left frame, applied in other home appliances, home appliances, applications, etc., can solve the problems of head shaking, damage, single function, etc., to achieve the effect of easy and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

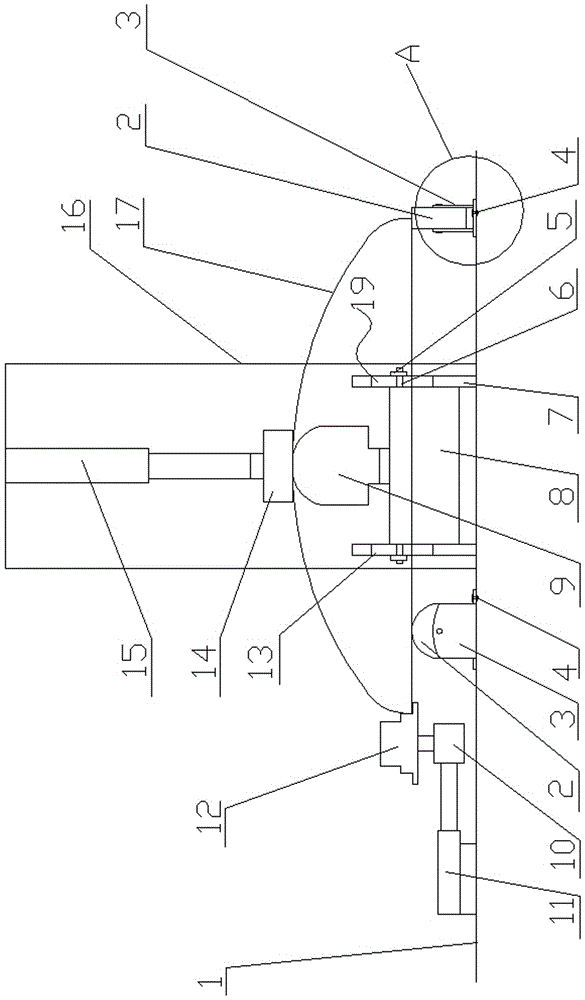

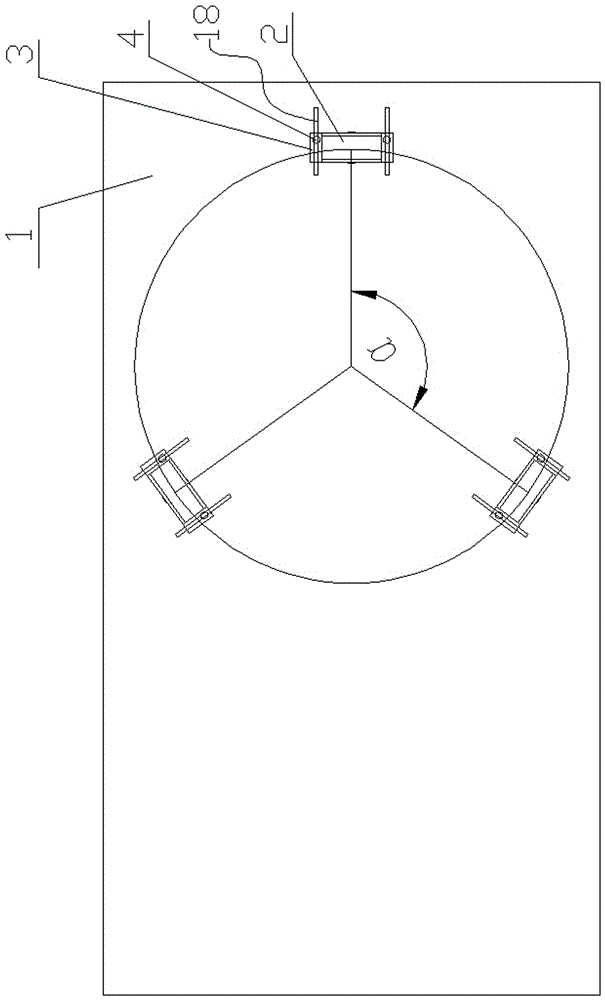

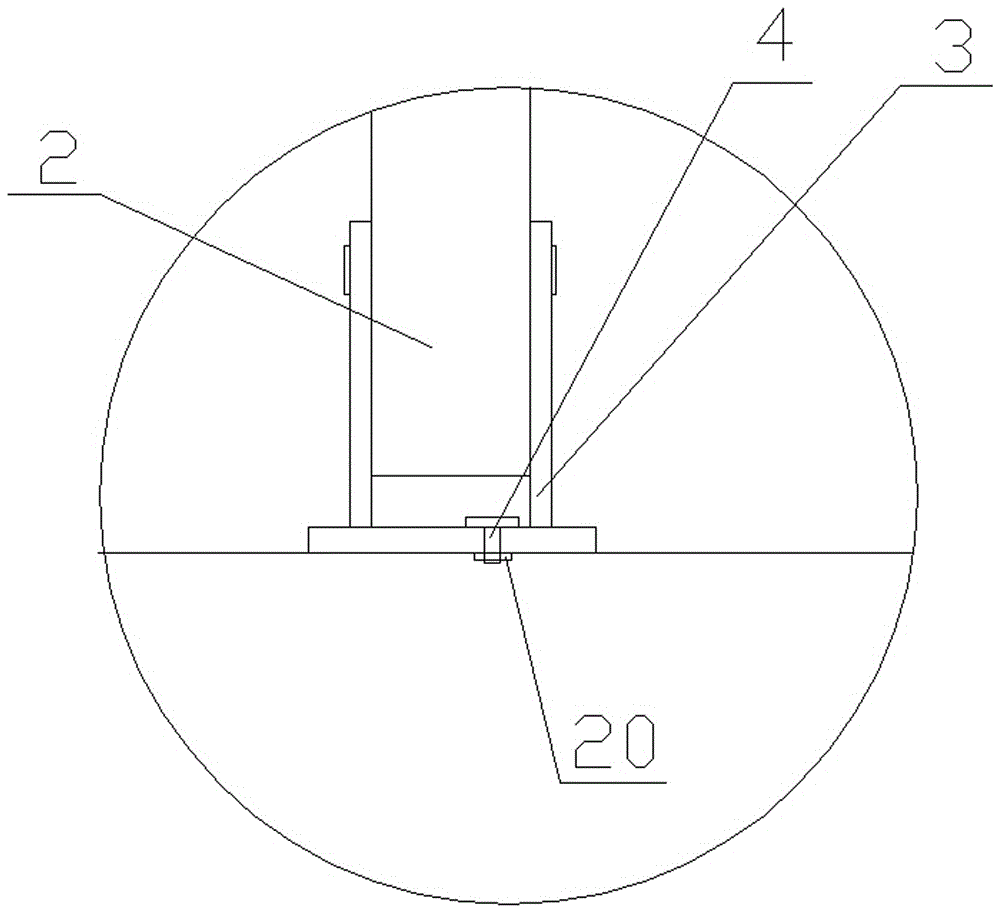

[0015] Such as Figure 1 to Figure 3 As shown, a kind of head shrinking machine of the present invention, it comprises workbench 1, and described workbench 1 is provided with the vertical lower jack column 9 that is axially fixedly connected with motor 8 rotating shaft, vertical lower jack column 9 The upper end of is set as a sphere. Between described motor 8 and workbench 1, be provided with motor elevating frame, described motor elevating frame comprises left frame 13 and right frame 7 that are arranged symmetrically, and described motor 8 is positioned at left frame 13 and right frame 7 In between, symmetrical vertical chute 19 is provided on the opposite sides of left frame 13 and right frame 7, and horizontal bolt 6 is fixedly arranged on the position corresponding to vertical chute 19 on the described motor 8, and horizontal bolt 6 The end of 6 passes through the vertical chute 19, and the transverse bolts 6 are respectively connected with the left frame 13 and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com