GH4169 high-temperature alloy round rod finish forging method

A GH4169, 1. GH4169 technology, applied in the precision forging field of GH4169 high-temperature alloy round bar, to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

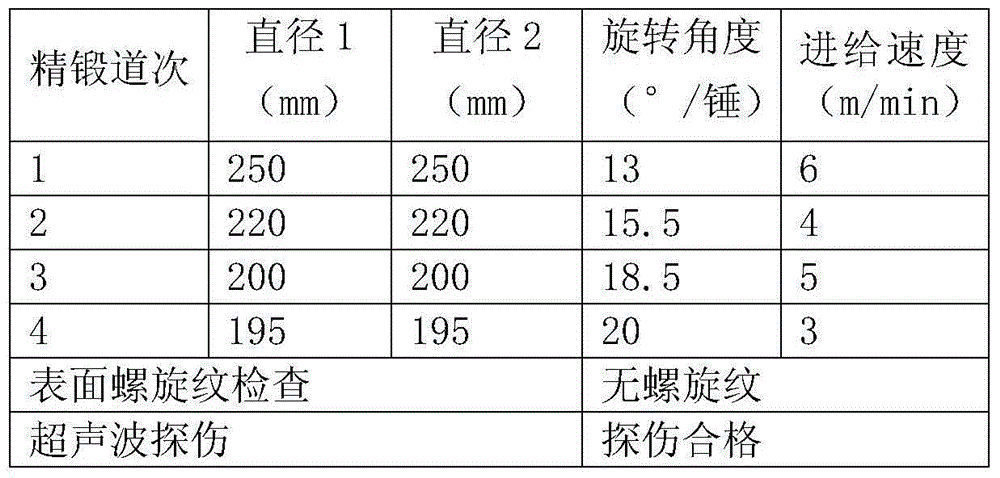

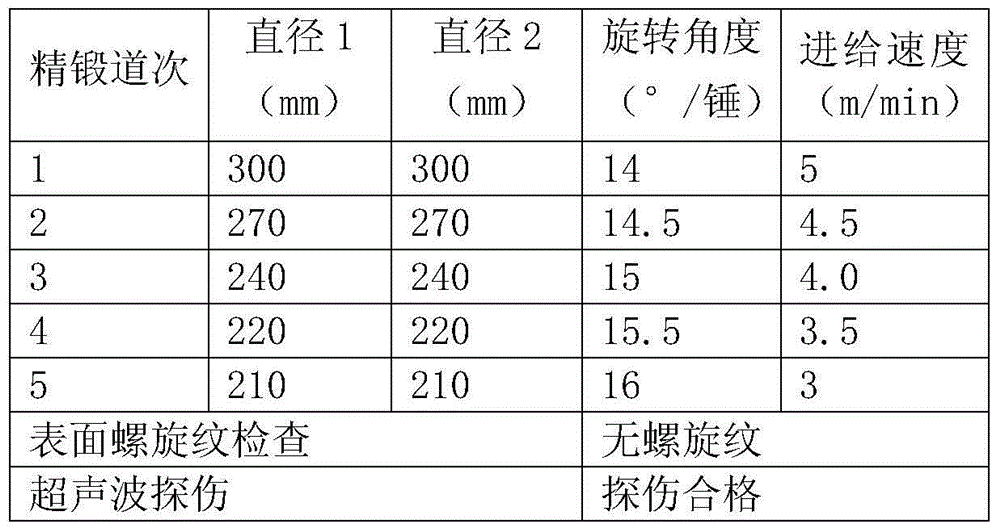

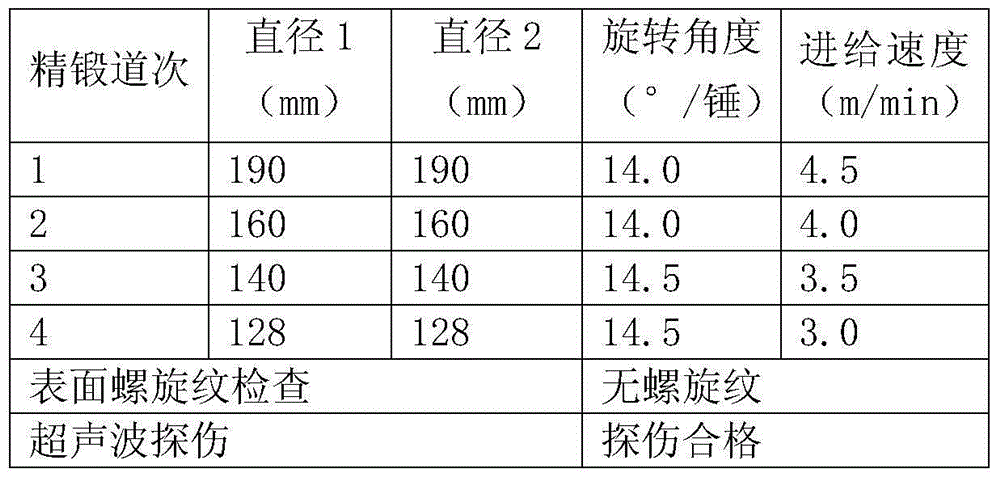

[0014] GH4169 high-temperature alloy round rod precision forging method, including the step of sending the GH4169 high-temperature alloy round rod blank into the precision radial forging unit for forging, the blank is sent into the precision radial forging unit for forging, the round bar The angular rotation parameter of the blank is 13-20° / hammer, and the feed speed of the blank is 3-6m / min.

[0015] The precision forging method for GH4169 superalloy round rods of the present invention focuses on the improvement of the operating parameters of the precision radial forging unit. Specifically, when the precision radial forging unit is working, the billet angle rotation parameter is 13-20° / hammer, that is, After each beating, the unit rotates the billet by 13-20°, the more preferred angle rotation parameter is 14-16° / hammer, and the billet angle rotation parameter of each pass increases grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com