Full-automatic machining tool punching center hole through saw

A center hole, fully automatic technology, used in metal processing mechanical parts, clamping, support and other directions, can solve the problems of inconvenient adjustment when switching between drilling and milling processes, reducing production and processing efficiency, complex equipment structure, etc., to achieve simple structure and cost. Low, improve the degree of automation, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

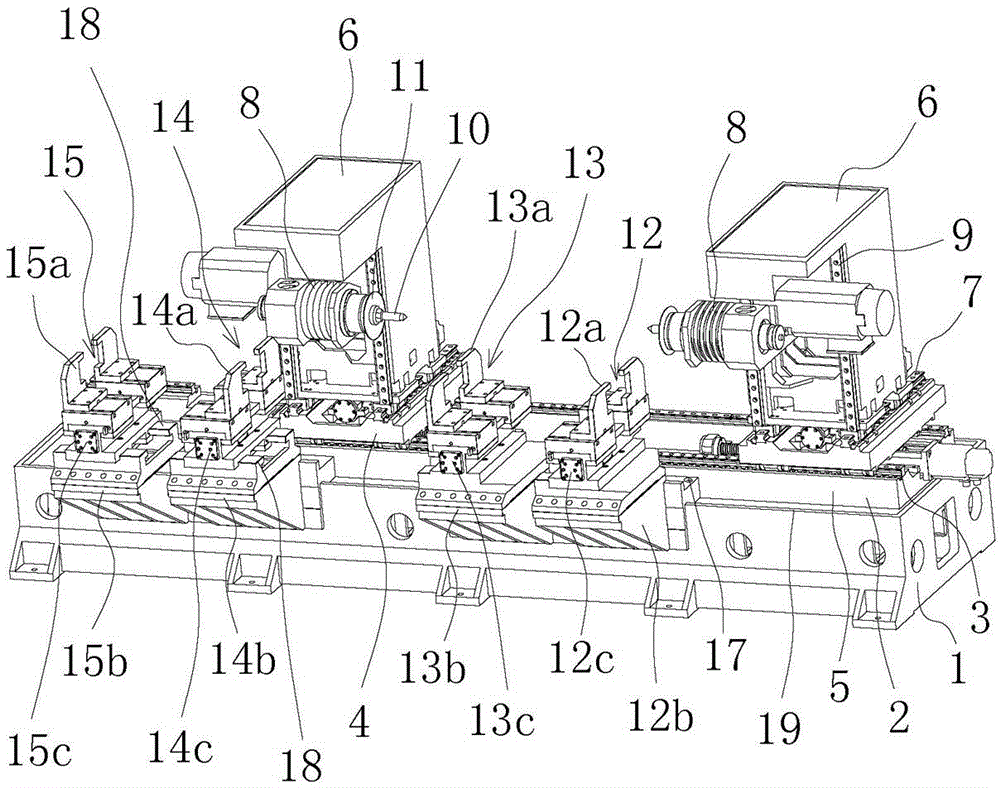

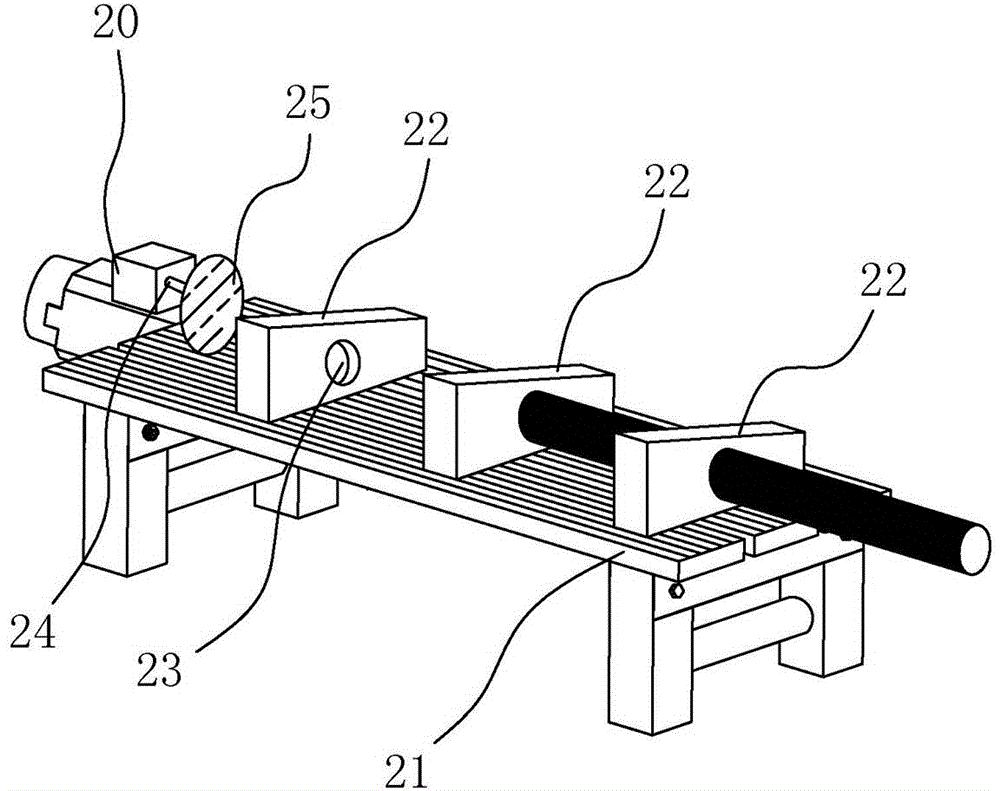

[0017] Such as figure 1 , figure 2 As shown, the fully automatic sawing center hole machine tool includes a bed base 1 and a saddle 2 arranged on the bed base 1. There are two horizontal guide rails 3 arranged in parallel on the slide saddle 2. The horizontal guide rail 3 is provided with a left The slide table 4 and the right slide table 5, the left slide table 4 and the right slide table 5 are all provided with a power box 6, and the left slide table 4 and the right slide table 5 all have a longitudinal guide rail 7 for the power box 6 to move back and forth. The box 6 is equipped with a horizontally arranged power head 8 and the power box 6 also has a vertical track 9 for the power head 8 to move up and down. The end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com