Novel granular material short-distance horizontal conveying device

A granular material and horizontal conveying technology, which is applied in packaging and other directions, can solve the problems of short service life of material conveying equipment, slow material conveying speed, high repair and maintenance costs, and achieve the effects of high cost performance, simple cleaning, and improved purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0024] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

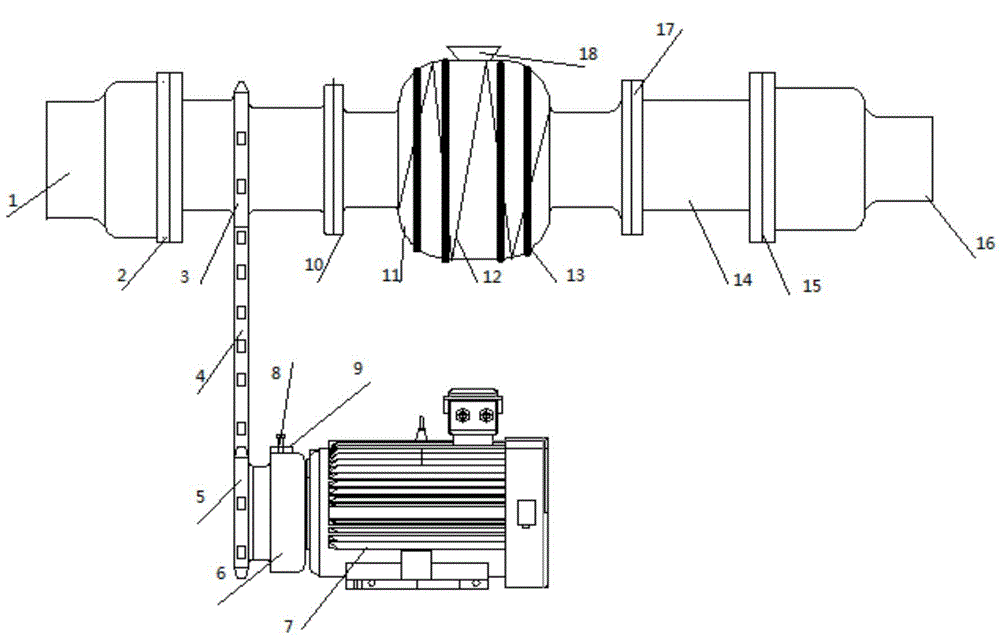

[0025] The new material conveying device includes feed inlet 1, large flange A2, sprocket A3, transmission chain 4, sprocket B5, working head 6, motor 7, adjusting bolt 8, frame 9, small flange A10, and casing 11. Spiral attachment 12, filter screen 13, pipe 14, large flange B15, discharge port 16, small flange B17 and hand hole 18, the left end of the pipe 14 is provided with the feed port 1, close to the The large flange A2 is fixed on the pipeline 14 at one end of the feed inlet 1, the sprocket A3 is fixed on the left end of the pipeline 14, and the transmission chain 4 connects the sprocket A3 and the sprocket B5 , the sprocket B5 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com