Automatic debugging system and method

An automatic calibration and transportation system technology, applied in the direction of stereo system, transportation and packaging, character and pattern recognition, etc., can solve problems such as unevenness and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

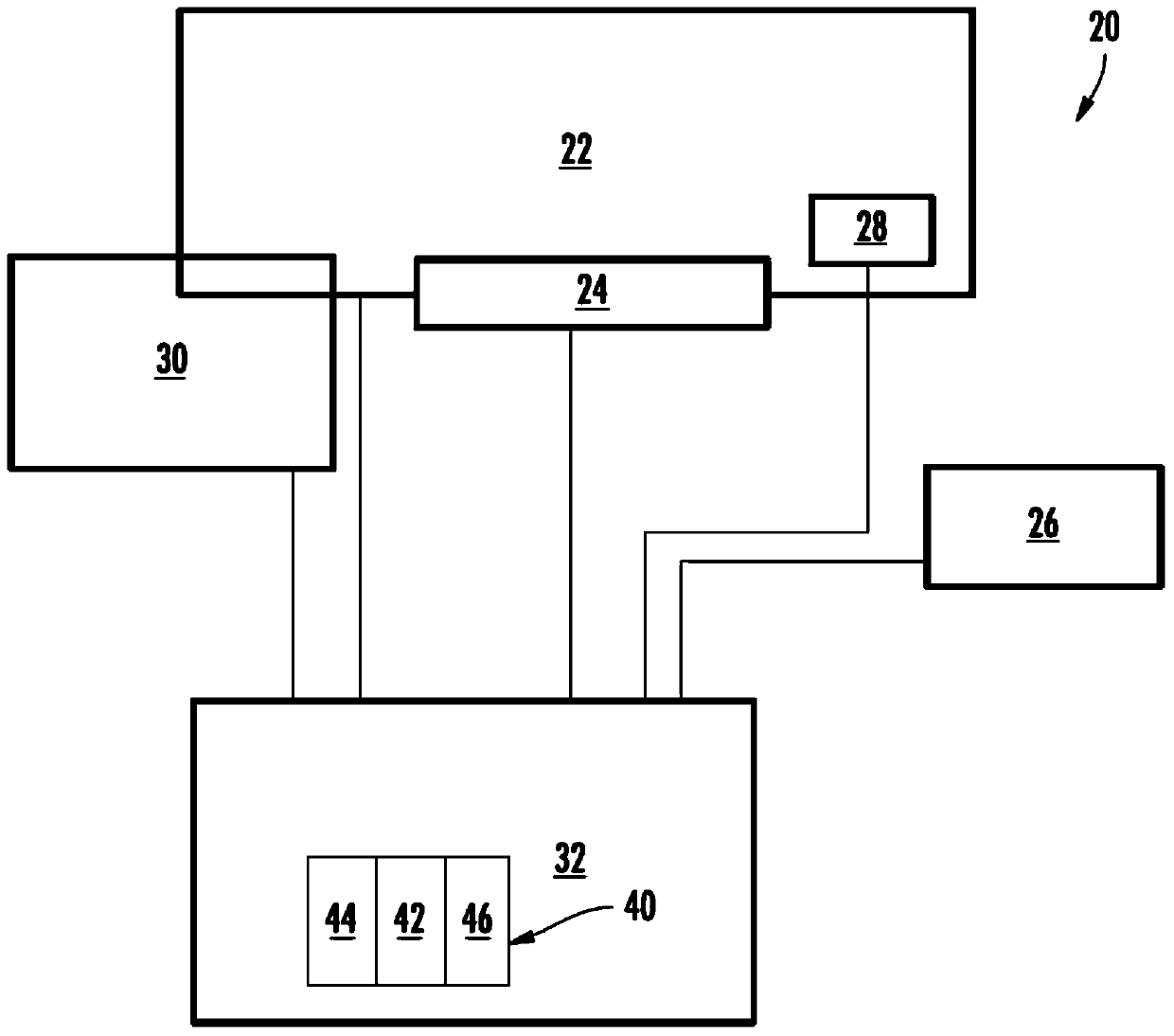

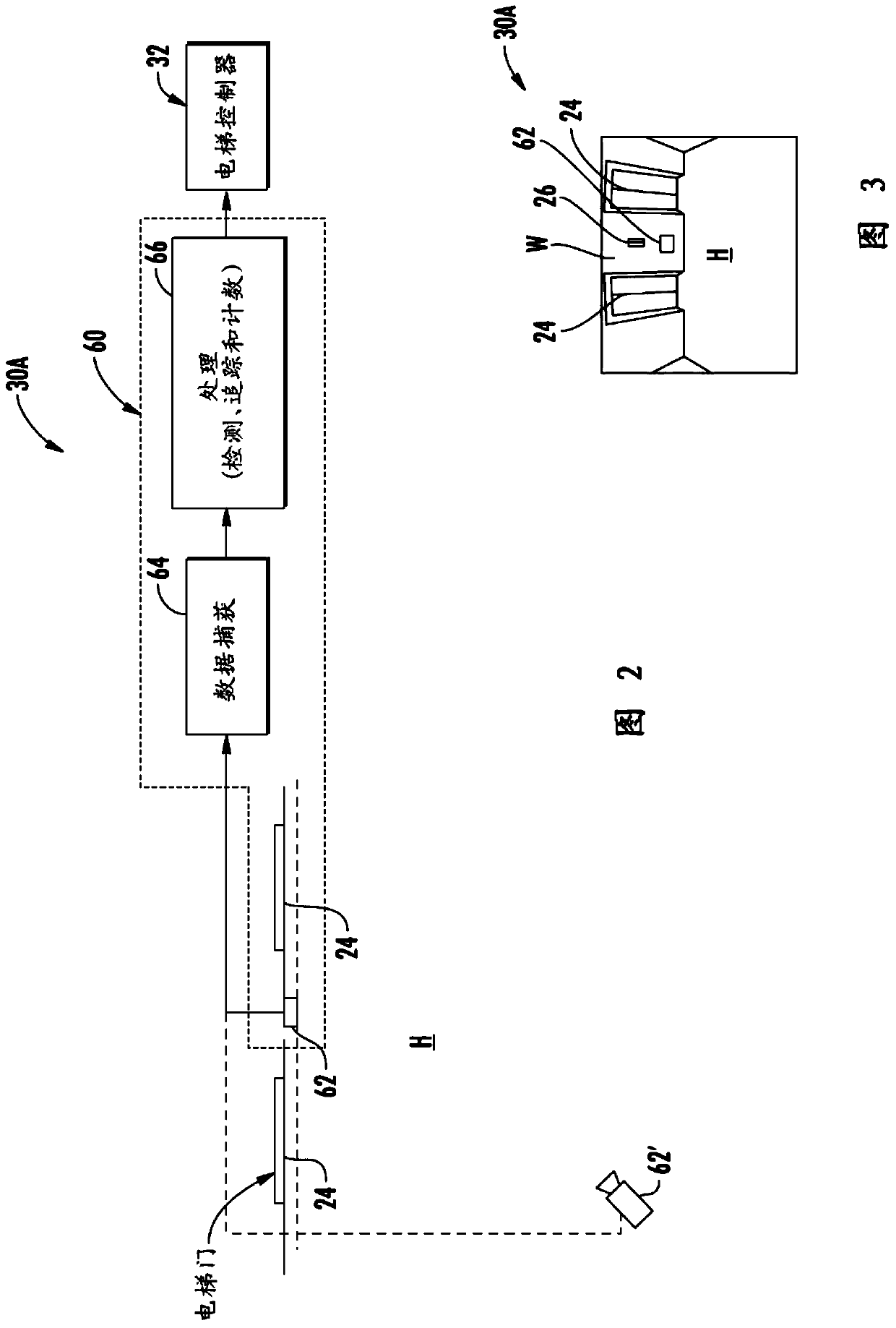

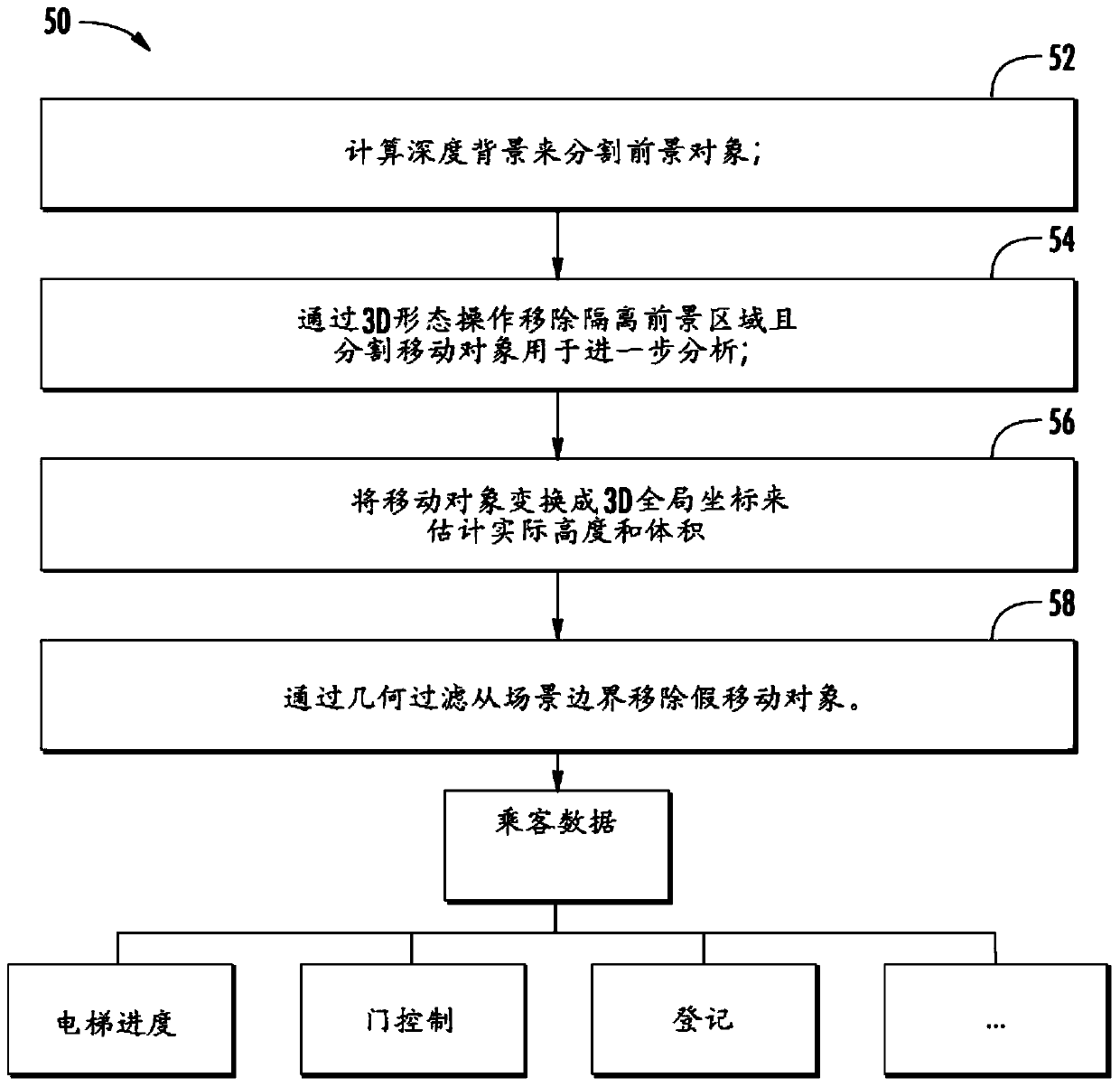

[0048] figure 1 A passenger transportation system 20 is schematically illustrated, such as an elevator system. System 20 may include elevator car 22 , elevator doors 24 , hall phone 26 , car operating panel (COP) 28 , sensor system 30 , and control system 32 . It should be appreciated that while an elevator system is disclosed and described herein by way of example, other passenger transportation systems, such as public transportation, would also benefit. It should also be understood that although a particular system is individually defined, each or any of the systems may be otherwise combined or separated by hardware and / or software.

[0049] The total amount of passenger travel time associated with elevator performance may include three time intervals. The first time interval may be the amount of time a passenger waits in the lobby for an elevator to arrive, hereinafter "wait time". The second time interval may be "door dwell time" or the amount of time the elevator doors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com