Basket carrier type counterweight elevator energy-saving apparatus and control system

A technology of energy-saving devices and regulating devices, which is applied to elevators, transportation and packaging, elevators, etc. in buildings, and can solve problems such as traction drive energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

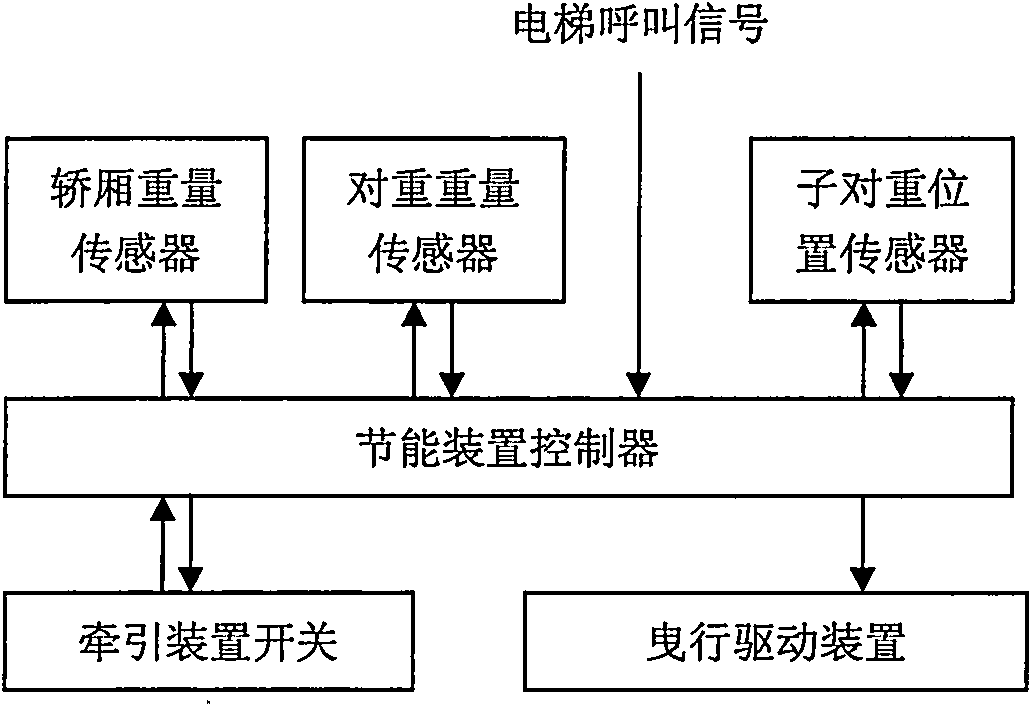

[0024] 1. Introduction to the functions of the main components of the device of the present invention

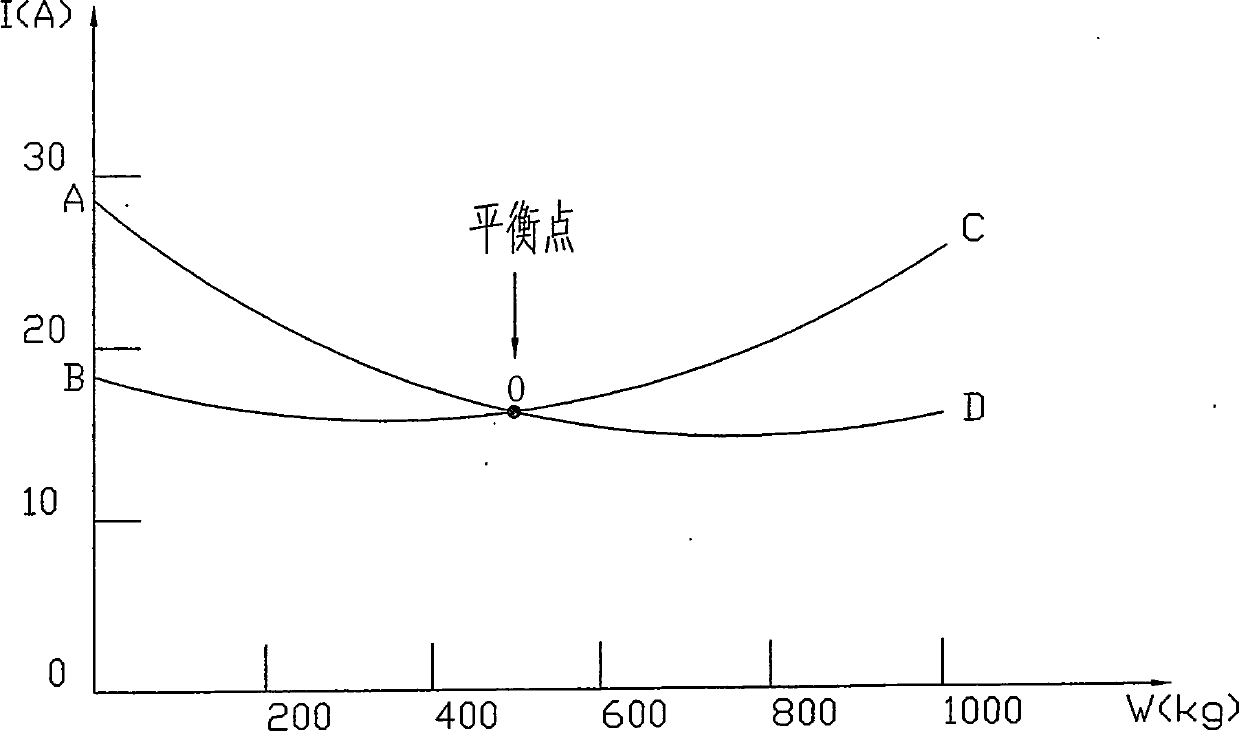

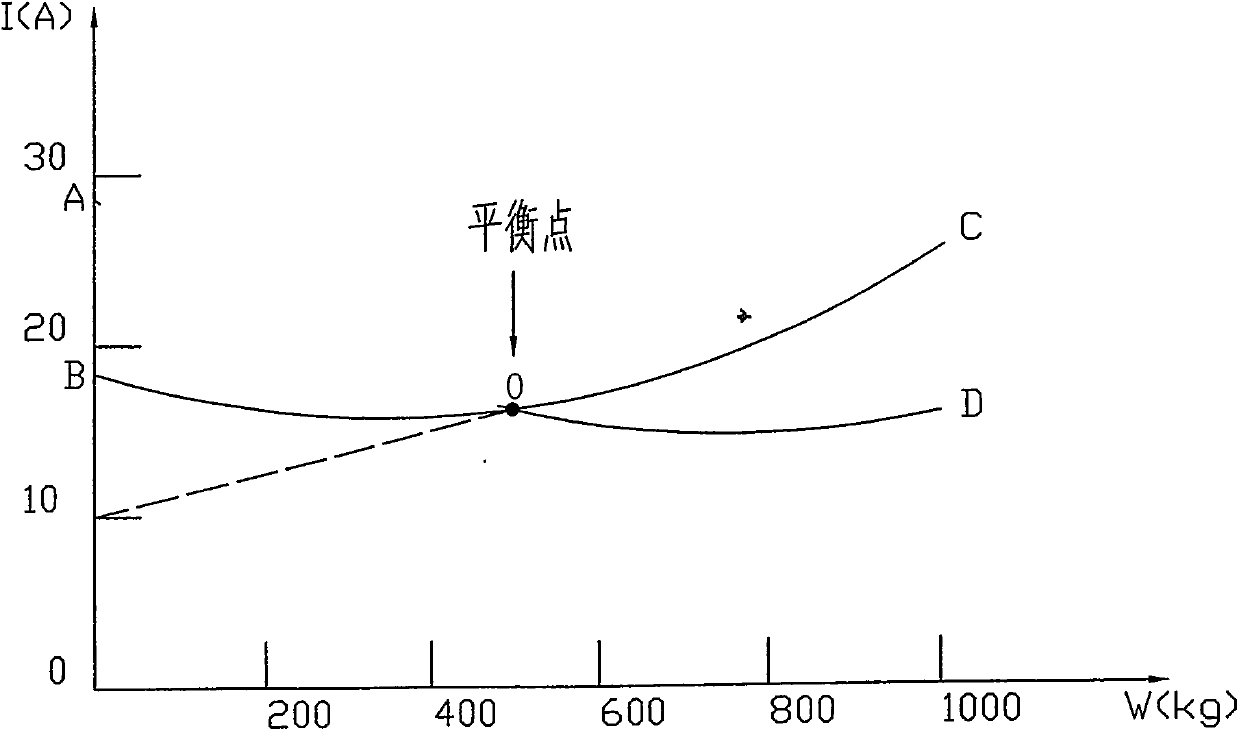

[0025] The sub-pairs are reused to balance the weight difference between the car 6 and the counterweight 17 on both sides of the traction sheave 1 . from Figure 5 It can be seen that a set of energy-saving device has only one sub-counterweight frame, and traction wire rope adjustment devices 7 are installed on the left and right sides of the car bottom to pull the sub-counterweight lower pulley 14. in the upper and lower spaces in the middle.

[0026] The hoisting or unloading of the neutron counterweight during elevator operation is realized by the traction device 7 tightening and loosening the traction wire rope 4. The action and range of the traction device 7 are subject to the dynamic balance between the car and the counterweight accepted by the energy-saving device. Control instruction.

[0027] The counterweight is on the bottom floor, and when the empty car needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com