Ink capable of producing corrugated glaze effect

A technology of ink and hydrophobic compound, which is applied in ink, household utensils, applications, etc., can solve the problem of ceramic surface crack sinking and pure matte effect, and achieve the effects of small environmental impact factors, good antifouling effect, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

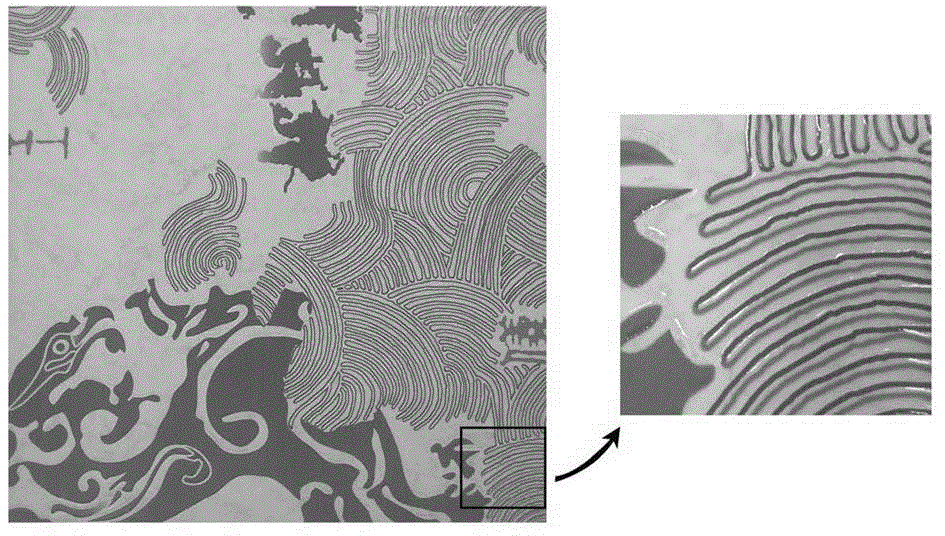

[0036] The similar stone cracks and depressions prepared by the prior art cannot achieve a pure matte effect. The present invention provides a ceramic ink with a glaze removal effect and its preparation method and use method, aiming to overcome this defect.

[0037] The purpose of the present invention can be achieved through the following technical aspects:

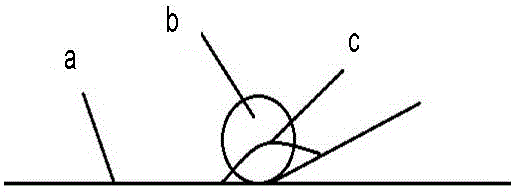

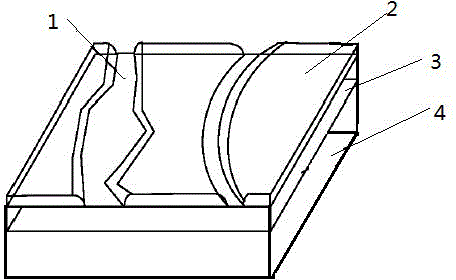

[0038] By adding a certain proportion of low-molecular hydrophobic compounds into the ink, the pattern formed has strong hydrophobic properties, and the glaze sprayed or poured on it cannot stay on the surface, forming a special glaze-removing effect, and forming a uniform pattern according to the pattern change. Bump texture. Then it is fired at high temperature, and then polished to form a strong contrast effect of light and dark.

[0039] The hydrophobic ink used in the inkjet ink is mainly composed of solvent, hydrophobic compound and organic colorant, the ratio of which is 94-99% of solvent, 0.1-5.0% of hydrophobic...

Embodiment 1

[0058] The preparation method of the present invention may comprise the following steps:

[0059] 1. Prepare the surface glaze layer slurry and transparent glaze slurry according to the required ratio, wherein, the dosage ratio of the surface glaze layer composition material to the solvent is 1g: 0.4mL, the solvent in the surface glaze layer slurry is water, and the surface glaze layer The composition is: by mass percentage, SiO 2 : 59.57%; Al 2 o 3 : 25.55%; Fe 2 o 3 : 0.29%; TiO 2 : 0.12%; CaO: 0.28%; MgO: 0.11%; K 2 O: 4.47%, Na 2 O: 2.80%, P 2 o 5 : 0.30%, ZrO 2 6.21%;

[0060] The dosage ratio of transparent glaze layer composition material to solvent is 1g: 0.35~0.45mL, the solvent in the transparent glaze slurry is water, and the transparent glaze composition is: by mass percentage, SiO 2 : 53.87%; Al 2 o 3 : 14.38%; Fe 2 o 3 : 0.17%; TiO 2 : 0.16%; CaO: 11.29%; MgO: 3.21%; K 2 O: 1.05%; Na 2 O: 5.27%; IL: 7.14%; ZnO: 2.58%;

[0061] 2. Self-made inkj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com