A preparation method of inkjet permeable travertine polished brick

A technology of inkjet infiltration and polishing bricks, applied in the field of ceramic building materials, can solve the problems of incapable of rich and changeable brick surface design, cumbersome preparation process, no feeling of holes, etc., to achieve high controllability of travertine effect and rich and changeable color. , good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

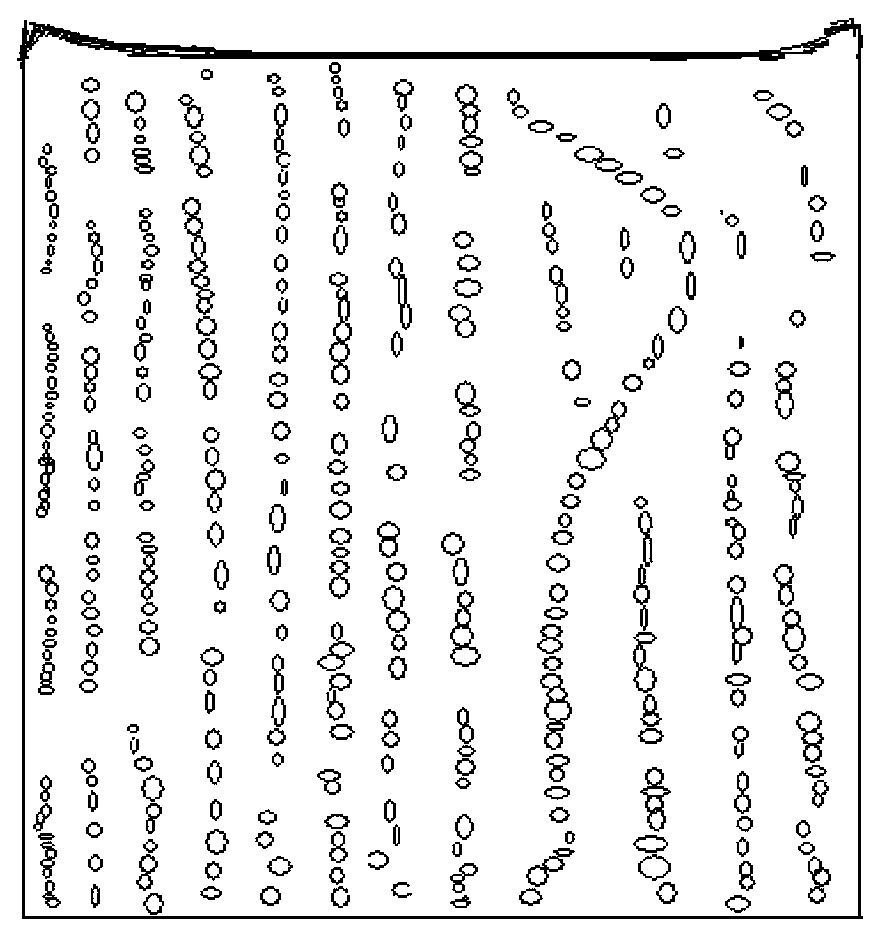

[0025] The invention provides a method for preparing an ink-jet permeable travertine polished brick. The ink-jet permeated travertine polished brick comprises a primer layer and a surface layer from bottom to top. In the fabric layer, holes with rich layers are formed according to the pattern texture. Since the pore-forming agent is lighter in weight than the mixed powder, it basically gathers on the surface according to the fabric texture after the fabric is made. After drying at 50-200°C (such as 50-150°C or 150-200°C), the pores are on the surface of the fabric layer. Formed on and open outwards. The holes can have different shapes and sizes. Holes can be formed in various shapes, such as triangles, quadrilaterals, circles and other shapes. The diameter of the hole may be 1-15 mm.

[0026] The fabric layer is also infiltrated with an inkjet infiltration pattern layer. Preferably, the inkjet penetration pattern layer corresponds to the holes formed according to the patte...

Embodiment 1

[0049] The preparation method of the present invention may comprise the following steps:

[0050] 1. Polyethylene oxide wax is selected as the pore-forming agent material. Prepare pore-forming agents of various colors according to the required ratio; wherein the pore-forming agents are white, light brown (0.15% dark brown ROG201), and light yellow (0.15% orange TD219). It is extruded into various shapes with lustrous pore-forming agent. The particle size is 1-15mm, and the ratio of pore-forming agent to fabric is 1:24. The chemical composition of the fabric is: SiO 2 : 66~72%; Al 2 o 3 : 20~23%; Fe 2 o 3 : 0.1~0.4%; TiO 2 : 0.1~0.3%; CaO: 0.2~0.4%; MgO: 0.1~0.3%; K 2 O: 2.5~3.5%; Na 2 O: 2.5~3.5%; P 2 o 5 : 0.2~0.5%; ZrO 2 : 1~3%, the whiteness is 55~65°, and 2.0~4.0% active silica is added to the fabric.

[0051] 2. According to the secondary material distribution process, the adobe is pressed into shape. Three sheets of film are used. The first sheet of cloth is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com